AMETEK 7230 HT Digital Probe User Manual

Page 20

18

For probes ordered with only 1 temperature sensor (i.e.

T1 or R1), a temperature reading is taken on that one

temperature sensor and that value is placed in all fi ve

temperature data locations in the string.

NOTE

: Data values outside the ranges specifi ed above

indicate an error condition.

A value of “999.9999” will be transmitted if there is

an error in the product or interface levels. A value of

“-999.9” will be transmitted if there is an error in the

temperature sensor measurement.

Calculation of Checksum

All characters (from and including the start character

(‘^’) to and including the comma (‘,’) after the fi nal

temperature digit) in the data string are added up to a

byte (8-bit) value. Take the upper nibble (4-bits) and

lower nibble (4-bits) of that byte and convert each

nibble value to its equivalent ASCII character.

For example:

If all the characters add up to 0xA5 (hex); it would

transmit an ‘A’ and a ‘5’ char to represent the upper and

lower nibble values. The 2-digit ASCII checksum (CC)

would be: 0x41 0x35 (or the ASCII equivalent chars ‘A’

‘5’).

Data Transmission Example

The following example represents the data transmitted

from a 7235 HR Digital Stik.

The following example represents a full transmission

data string (139 bytes) from a 7235 HR Digital Stik

probe with the following information (Bytes 0 - 135 are

used to compute the checksum):

NOTE

: The Level data in the following chart may not

be representative of a valid product level. The data is

for demonstration purposes only.

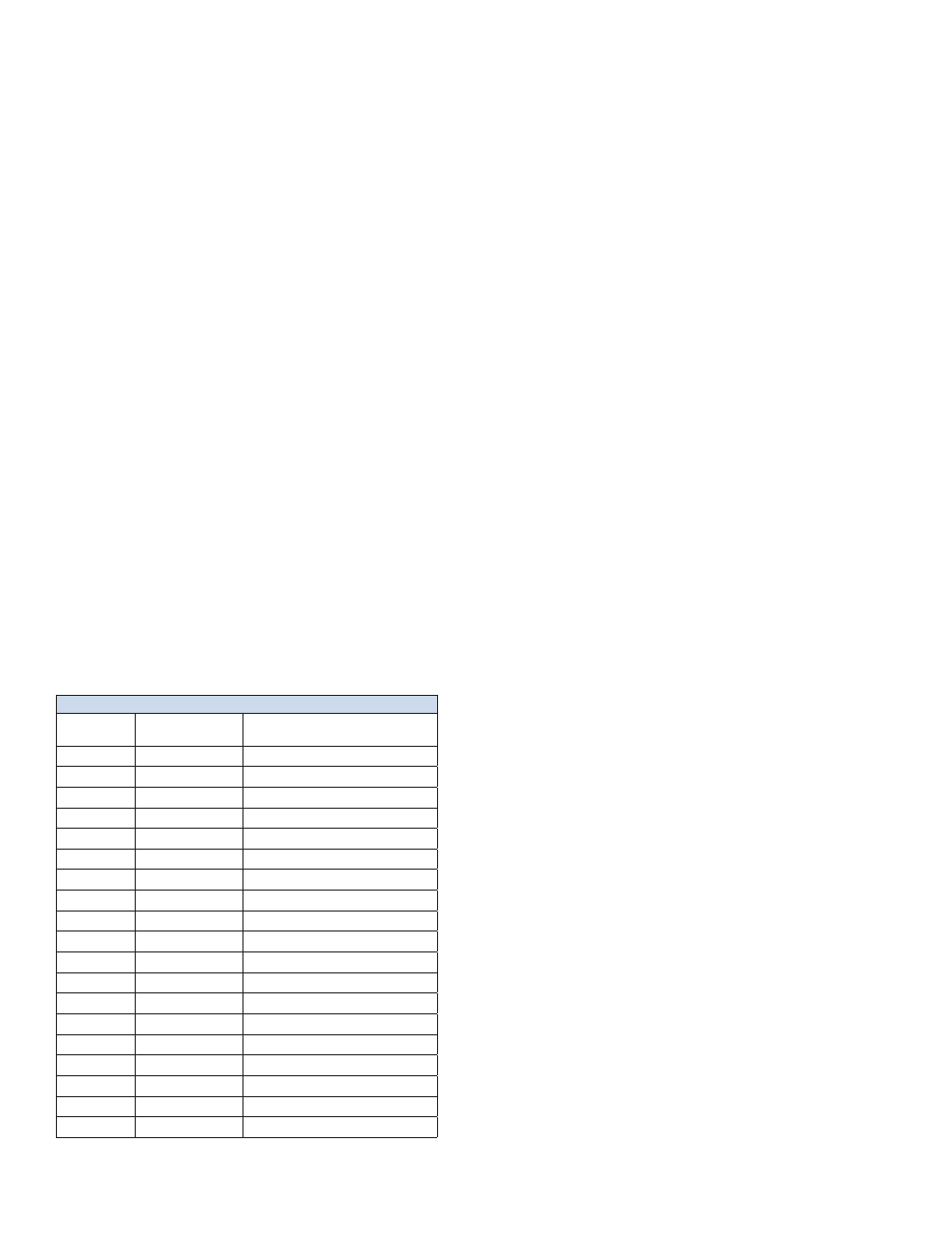

Data Transmission

Byte #s

ASCII Chr

String

Level Name

0-1

^,

Start Character

2-10

123.4567,

Product 1

11-19

456.7890,

Product 2

20-28

654.3212,

Product 3

29-37

987.6543,

Product 4

38-46

124.5789,

Product 5

47-55

234.5678,

Product 6

56-64

267.4310,

Product 7

65-73

478.2354,

Product 8

74-82

752.6143,

Product 9

83-91

891.4578,

Product 10

92-100

002.5389,

Interface 1

101-107

+122.1,

Temperature 1

108-114

+122.3,

Temperature 2

115-121

+122.5,

Temperature 3

122-128

+122.3,

Temperature 4

129-135

+122.1,

Temperature 5

136-137

CC

2-digit ASCII Checksum

138

Return

Section 4 - Basic Trouble

Shooting: 7230 HT Series

Magnetostrictive Probes

Symptoms:

No Signal

Intermittent Signal

Erratic Temperature reading

Faulty water level measurement

Faulty product level measurement

Diagnostics:

1.

Check error codes for 7231 HT Modbus probe

• Error Codes (page 10)

a) Value of 2000 in the product, interface or

temperature registers indicates a loss of signal.

b) Value of 1000 in the product or interface register

indicates a communication problem or a “dead”

probe.

2.

Check error codes for 7235 HT Digital probe

• Error Codes (page 18)

a) 999.9999 error of signal for product or interface

level.

b) -99.9 error of signal from temperature sensor.

(see page 18)

3. Locating the Problem Source

• Is the problem with the probe or elsewhere?

Connect a working (or demo) probe from another

tank to confi rm that the problem is related to the

probe and not the wiring or communications.

• Does the wiring (ground and signal) and power

meet the specifi cations? If not, you can have

erratic or complete loss of signal.

• Has the PLC/controller been setup properly to work

with this probe?

4. Floats

• Are the correct number of fl oats being used?, F1 is

one fl oat, F2 is two fl oats.

• Are the fl oats correctly installed? The product fl oat

must be positioned above the Interface (water)

fl oat.

• Were the fl oats supplied (or evaluated) by APT?

Internal magnet must match probe.

• Are the fl oats “sticking” or moving freely? No

build-up on probe.

• Are the magnets in the product and interface fl oats

4 inches apart on a long probe?

5. Magnetic Fields

• Was the head of the probe accidentally

magnetized? This can be done in the fi eld and can

cause signifi cant problems. Degauss the head of

the probe.

• Is there a magnet fi eld in the tank? Pull the probe

partially out of the tank about 2 ft to see if the

problem is resolved.

6. Unexpected Readings

• Confi rm actual levels and temperature reading

directly from Probe. Compare these to known

values. This can be done manually in the fi eld.

Make sure that temperature sensors located

outside of the liquid are not being used to calculate

an average.

.