Chapter 3 programming & maintenance – AMETEK 955DQ Brik LDT User Manual

Page 7

7

1080 N. Crooks Road • Clawson, MI 48017 • 800.635.0289 • 248.435.0700 • Fax 248.435.8120 • www.AMETEKAPT.com

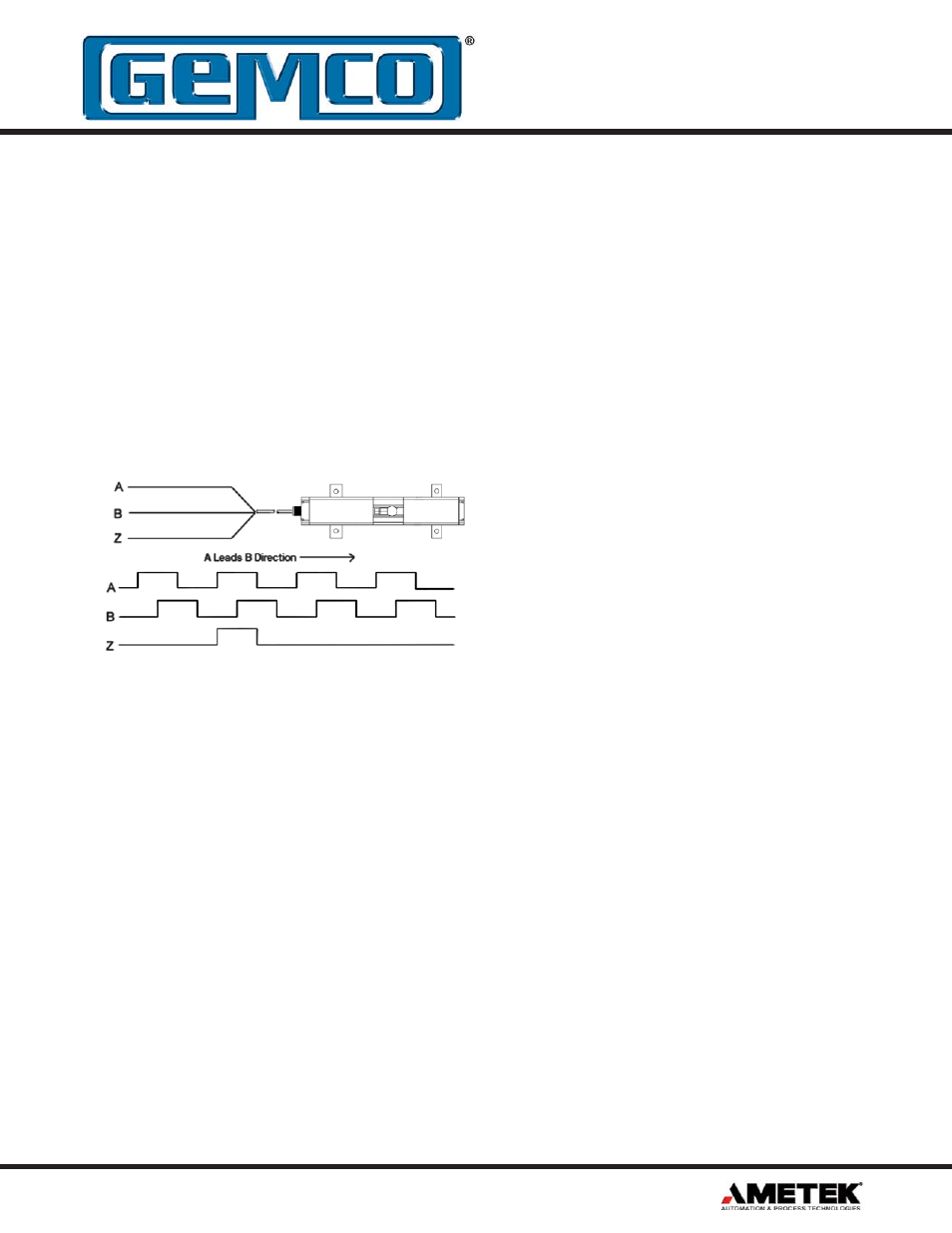

3.1 Quadrature Output

A new method of interfacing magnetostrictive transducers

offers customers an interface as common as analog

with the speed and accuracy of pulsed type signaling.

The GEMCO 955DQ LDT provides quadrature output

directly from the transducer to the controller (see drawing

below). The output from the transducer can be wired

directly to any incremental encoder input card, without

the need for a special converter module or PLC interface

card designed specifically for use with a pulsed output

magnetostrictive transducer.

The quadrature output provides absolute position data

in engineering units. This means that the need for the

calibration constant (wire speed) programming has been

removed, thereby eliminating the possibility of having an

improperly calibrated system. The output signal wires

are driven by differential line drivers, similar to the drivers

used in most magnetostrictive pulsed type transducers,

providing a high degree of noise immunity.

A unique feature of this transducer is a “burst” mode of

operation. An input on the transducer triggers a data

transfer of all the incremental position data relative to

the transducer’s absolute zero position. This can be

used to achieve absolute position updates when power

is restored to the system or anytime an update is needed

to re-zero or home the machine. Additionally, another

input to the transducer can be used to establish a “zero”

position for the transducer.

Chapter 3 Programming & Maintenance

3.2 Signal Connection Application Note

Overview

This application note will clarify the input and output

signals of the 955DQ quadrature probe.

Inputs

The quadrature probe has two inputs, the “zero” and

“burst” inputs. These inputs are “single ended”. That is,

the connection for each input consists of only one wire,

the corresponding signal wire. For these (single ended)

inputs, the signal is measured with reference to the

power supply ground, which is sometimes referred to as

“common”.

The quadrature probe is available with either +24 VDC

level signal thresholds or TTL level thresholds. The

signal voltage level required to activate the input for the

+24 VDC level signal is proportional to the power supply

voltage that the customer is supplying to the probe. This

level is approximately 41% of the power supply voltage.

For example, if the power supply voltage powering the

probe is exactly 24 VDC, the threshold voltage would be

approximately 9.84 volts.The TTL level threshold signals

are activated when these inputs exceed the typical TTL

level threshold, which is 2.0 VDC.

Additionally, for the 24 VDC level signals, the customer

can specify either a “sourcing” or “sinking” type of input.

A “sourcing” input type is pulled high internal to the probe.

To activate a “sourcing” input, the customer must pull the

signal lower than the threshold voltage to activate the

input. A “sourcing” input is usually driven by a “sinking”

output or a switch connected to ground. A “sinking”

input type is pulled low internal to the probe. To activate

a “sinking” input, the customer must pull the signal

higher than the threshold voltage to activate the input. A

“sinking” input is usually driven by a “sourcing” output or

a switch connected to the power supply.

It is important that the customer drive the signal levels

much greater or lower than the threshold voltages.

Asserting a signal with a voltage level close to the

threshold voltage could induce multiple activations of that

input (or none at all) and therefore produce unexpected

results or probe readings.