Application, Troubleshooting, Installation – Red Lion ITMS User Manual

Page 10

10

INSTALLATION

The unit is equipped with a universal mounting foot for attachment to standard DIN style mounting rails, including G profile rail

according to EN50035 - G32 , and top hat (T) profile rail according to EN50022 - 35 x 7.5 and 35 x 15. The unit should be installed in a

location that does not exceed the maximum operating temperature and provides good air circulation. Placing the unit near devices that

generate excessive heat should be avoided.

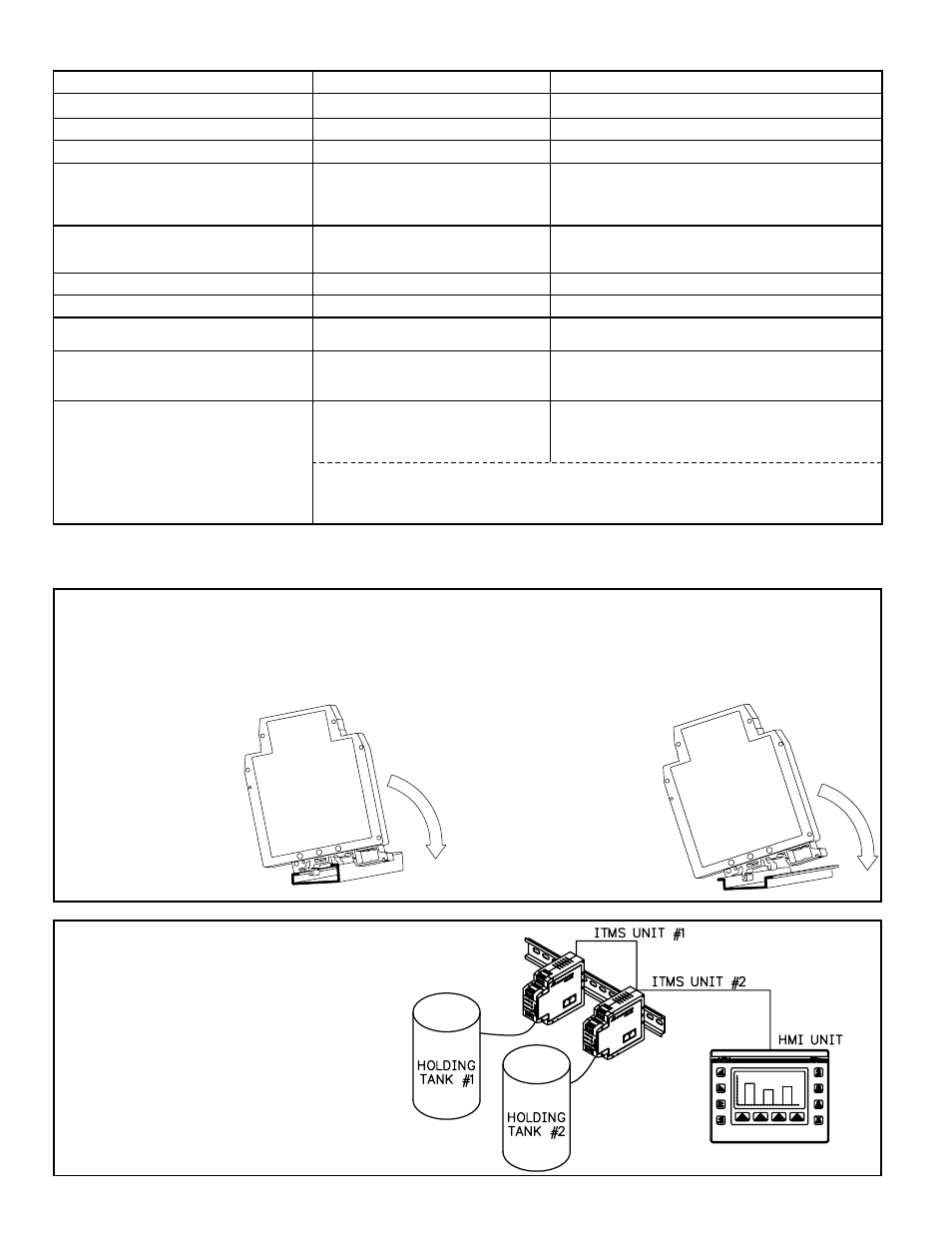

G Rail Installation

To install the ITMS on a “G”

style DIN rail, angle the module

so that the upper groove of the

“foot” catches under the lip of the

top rail. Push the module toward

the rail until it snaps into place.

To remove a module from the

rail, push up on the bottom of the

module while pulling out and

away from the rail.

T Rail Installation

To install the ITMS on a “T”

style rail, angle the module so

that the top groove of the “foot”

is located over the lip of the top

rail. Push the module toward the

rail until it snaps into place. To

remove a module from the rail,

insert a screwdriver into the slot

on the bottom of the “foot”, and

pry upwards on the module until

it releases from the rail.

APPLICATION

A chemical company wanted to remotely monitor the

temperature of several holding tanks. Using the ITMS, the

customer was able to receive, interpret, and store the

temperature readings via standard thermocouples. To provide a

remote display, the customer chose a Red Lion Paradigm HMI

(Human Machine Interface). The HMI communicates with the

ITMS modules and displays the information graphically,

providing an intuitive interface. As an added benefit, the ITMS

alarm setpoints can be adjusted from the HMI, while providing

reliable local alarm outputs.

TROUBLESHOOTING

* Can be monitored by accessing coils 9-16, or register 40025.

For further technical assistance, contact technical support.

PROBLEM

CAUSE

REMEDIES

Green LED will not light

Module power

Check module power connections and voltage level

Process Value not changing

Input signal

Check input signal connections and signal level

Incorrect scaling

Check input setup, scaling values, and re-download

Alarms disabled

Alarm threshold over range*; checksum

error; Input over/under range; open or

shorted probe*; calculated results over

+32000 or -32000; in Calibration Mode

Adjust alarm Setpoint and Hysteresis to ensure trigger

point is within -32000 to +32000 (See Alarm setup). For

other possible causes, see the remaining remedies

Process Value stays at 32001 or -32001

Input over or under range* due to:

Wrong TC, or RTD

Incorrect input type

Check input level

Check input type, and re-download

Process Value stays at -32002

NOTE: The ITMS’ serial settings must match the device that it is communicating with. If you do not know or

cannot recall the ITMS settings, they can be reset back to factory defaults. Simply jumper the Serial Default

terminal to Common, and cycle power. The serial settings will default to RTU mode, 9600 baud, 8 data bits, no

parity, with an address of 247.

Shorted RTD:*

Process Value stays at 32002

Open TC or RTD:*

Check input signal connections and probe

Process Value stays at 32100, Flashing

LEDs, alarms disabled

Parameter checksum*, loss of

parameter settings

Calibration checksum*

Re-download SFIMS file (reconfigures each parameter)

Perform calibration procedure

Will not communicate

(Green LED not flashing)

Incorrect serial settings (ITMS port)

Incorrect serial settings (computer port)

Incorrect wiring

Verify ITMS communications setup

Go to pull down menu SETTINGS, PC PORT SETTINGS

Try switching A+ and B- lines

Provide a common connection

Check input signal connections and probe

Process Value stays at +32003 or -32003

Calculated Temp. value over +32000 or

-32000

Check offset value, Register 40012

Process Value not changing or incorrect