Water quality requirements and specifications, Acceptable water quality specifications – HP Modular Cooling System User Manual

Page 60

Water quality and leveling requirements, and condensation management 60

Water quality and leveling requirements, and

condensation management

Water quality requirements and specifications

Closed-loop water must not contain any lime scale deposits or loose debris. The water must have a low level

of hardness, particularly a low level of carbon hardness. Filters must be used to remove free floating

particulates and be regularly maintained. Additionally, the water must not be so soft that it attacks the

materials with which it comes into contact. You must periodically add new fresh water, but also to remove

some enriched water. HP recommends a #30 mesh filter is recommended for filtering water entering the

MCS-200 unit and a 1 µm filter for prolonged performance.

Also consider the required set point for the water temperature. Temperatures near or below 0ºC (32ºF) mean

that the chilled water plant condenser is very close to or below the freezing point of the water. The chilled

water temperature to be supplied to the MCS-200 unit is 5ºC (41ºF). Freezing water can cause a blockage

and damage to the unit. Therefore, an additive such as glycol might be necessary to lower the freezing point.

However, the heat transfer potential of the water is lower, so the equipment must be derated properly.

In a cooling loop, metallic materials in a pipe distribution network are in constant contact with recirculating

liquid and can react with impurities to cause corrosion that can develop into leaks or form deposits and

blockages.

The rate of galvanic corrosion depends on the electrical potential between the two dissimilar metals and the

temperature of the liquid.

A 10-degree increase in water temperature can double the rate of corrosion.

For more information, see the HP Modular Cooling System Site Preparation Guide on the HP website

Acceptable water quality specifications

Closed-loop water must not contain any lime scale deposits or loose debris. The water must have a low level

of hardness, particularly a low level of carbon hardness. Filters must be used to remove free floating

particulates and regularly maintained. The water must not be so soft that it corrodes the materials that it

comes into contact. You must periodically add new fresh water, and remove some of the enriched water. HP

recommends a #30 mesh filter for filtering water fed to the MCS-200 and a 1 µm filter for prolonged

performance.

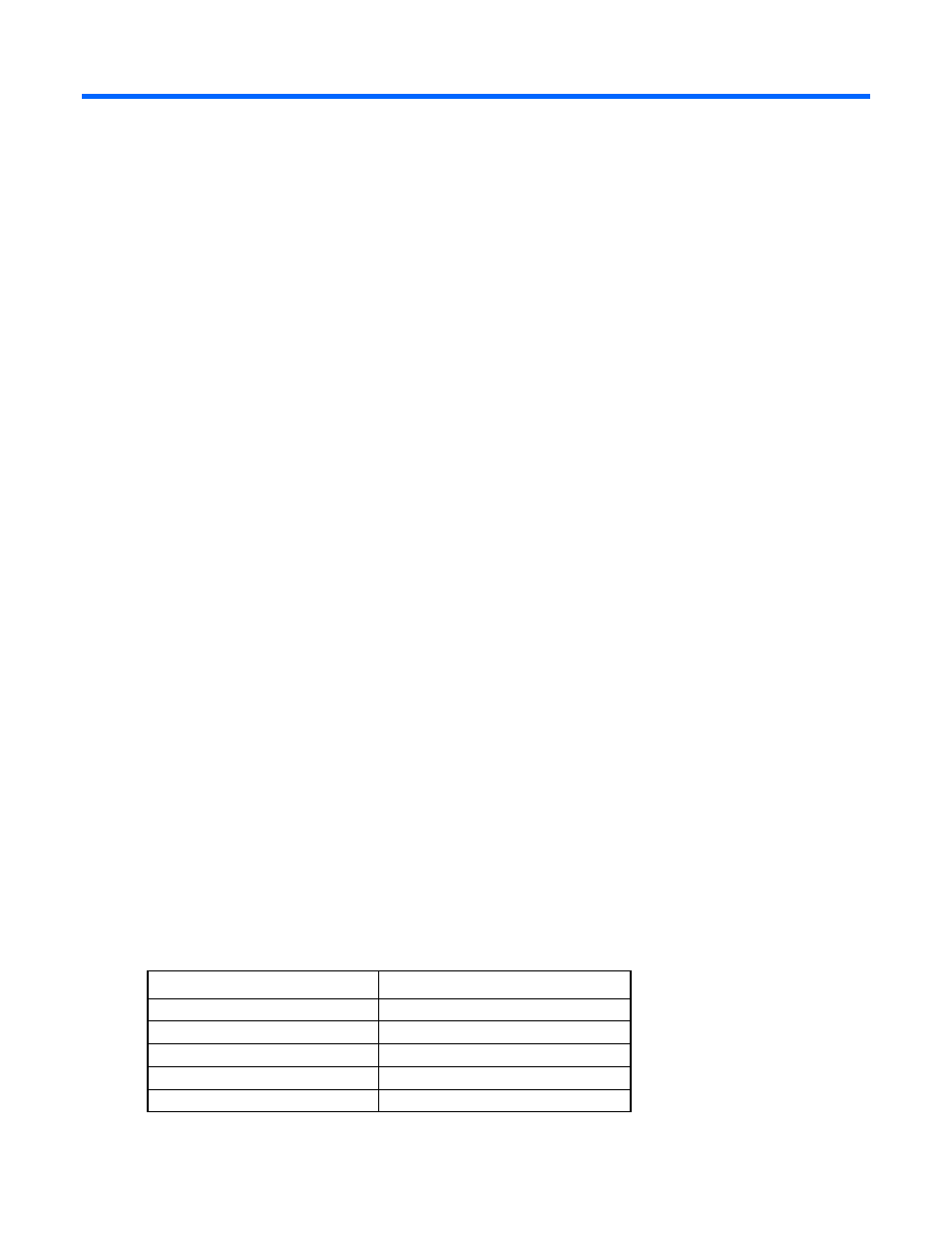

The following values are water quality ranges required for continuous quality of performance.

Parameter

Range

pH

7-9

Specific conductance at 25ºC (77ºF) <2500 µmhos

Sulfur (SO

4

), total

<100 ppm

Chloride (Cl)

<50 ppm

Sulfide (S)

<10 ppm