Caution – Sterlco Micro Series Water Temperature Control Unit User Manual

Page 14

Page 14

MICRO Series Water Temperature Control Units

3-4 Piping

Considerations

for Permanent Installations

We recommend an optional (or customer-installed) strainer on the COOLING

WATER IN inlet.

The unit must have at least 16 psig (110.32 kPa/1.1 bars) water supply pressure

to prevent pump cavitation that can be caused by the water “flashing” to steam.

To avoid damage to the pump or other components, make sure that maximum

supply pressure does not exceed 40 psig (275.8 kPa/2.8 bars).

Keep restrictions to a minimum by using proper inlet pipe sizing. If the water

supply piping is larger than ¾”, reduce the size at the unit. The table below

contains the pipe sizes that are used in the unit.

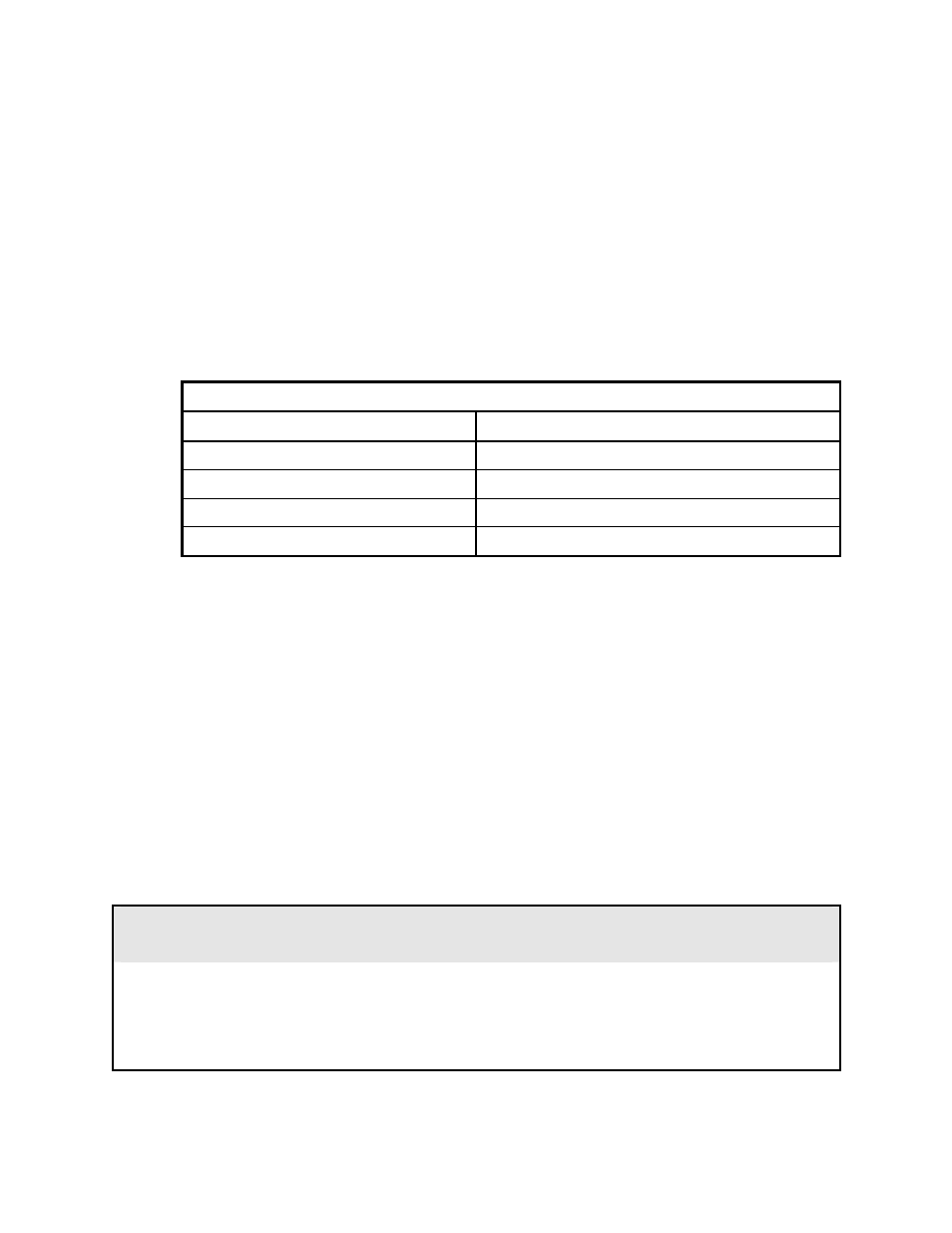

Pipe sizes for ½ hp and ¾ hp (0.37 kW and 0.56 kW) units

Location

Size in inches NPT

Process delivery

¾”

Process return

¾”

Water supply

¾”

Drain ¾”

Common black pipe is recommended for permanent installations. MICRO Series

water circuit piping is non-ferrous (stainless steel and brass) and reacts electro-

chemically with ferrous metallic materials such as iron. Some water contains

dissolved minerals that greatly accelerates the reaction between dissimilar metals.

Non-ferrous piping is recommended to minimize galvanic action. If piping must

be copper, use dielectric unions at the unit.

3-5 Piping Considerations for High Mobility Installations

Mobile MICRO Series systems must use high quality hose rated for at least 150

psig and 250

°F (1,034.25 kPa/10.34 bars and 121ºC).

Quick disconnects may be used for mobility, although they cause a drop in

pressure. If used, they must be sized carefully to minimize pressure drop. Don’t

use quick disconnects with check valves unless absolutely necessary.

!

CAUTION

Non-relieving quick connect fittings or check valves on the water supply

must have a pressure relief piped to the drain.

Failure to do so could result in a dangerous over-pressure condition!