Shaft drive yoke drive clockwise cam screws – Dwyer Mark User Manual

Page 13

12

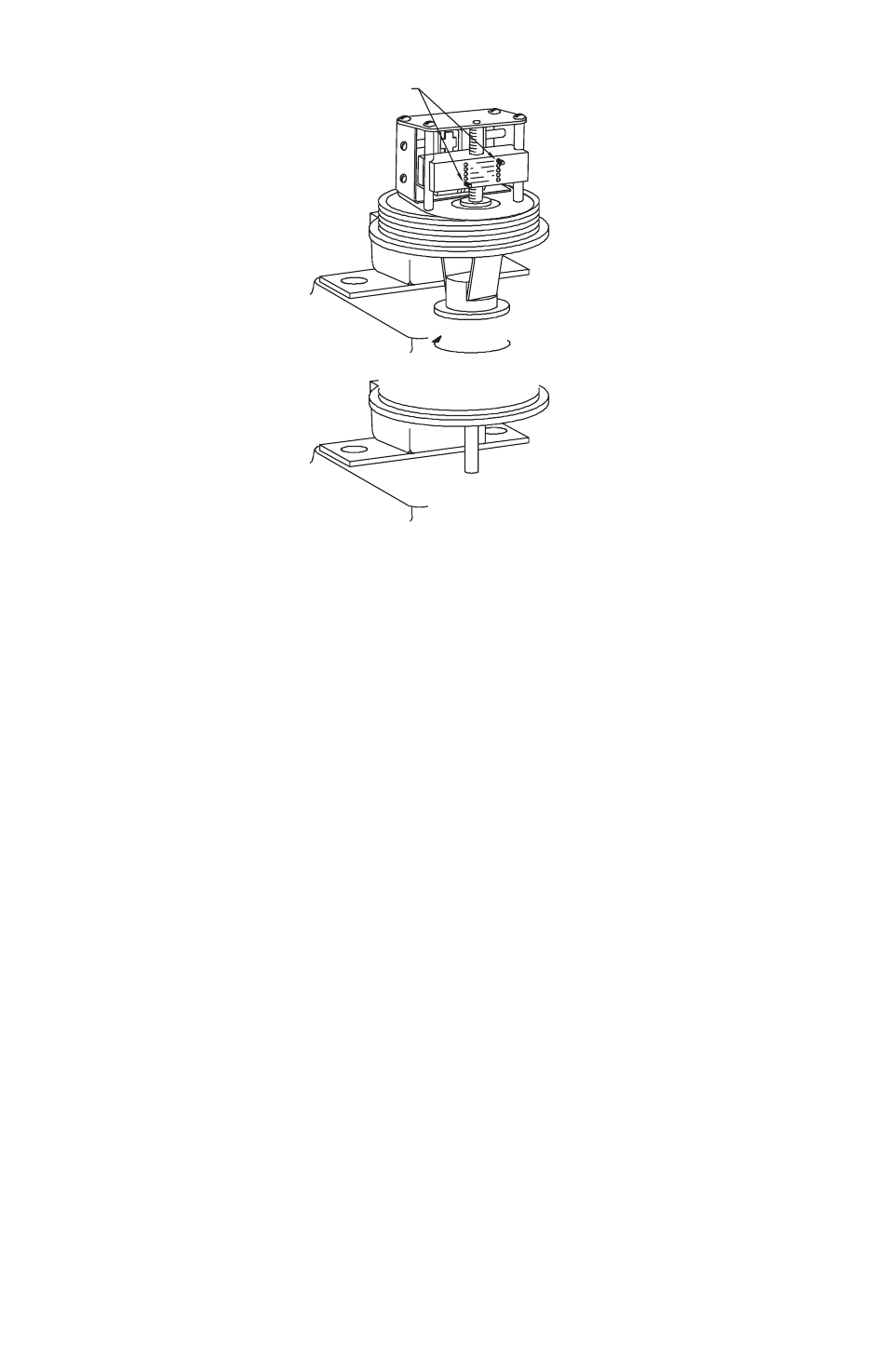

MARK 3 DIRECT AND LEVER DRIVE INSTALLATION

SHAFT DRIVE

YOKE DRIVE

CLOCKWISE

CAM SCREWS

1

2

A

B

C

D

E

INSTALLATION PROCEDURE

Mount the switch as necessary, concentric and perpendicular over the rotating shaft that is to be monitored. Direct drive

yokes are available in many widths and lengths to fit your needs (Yokes are fabricated from spring temper stainless

steel. Do not attempt to fabricate your own yokes.) Shaft drive units require an appropriate coupling (flexible type

recommended) to the shaft being monitored.

ADJUSTING PROCEDURE

1. Remove cover by unscrewing. Take care to keep threads clean and free from damage.

2. Clockwise rotation of the yoke or shaft will move the bar up, counterclockwise moves it down.Switches are set at

the factory for approximately one revolution of the yoke or shaft to actuate switch #1. Notice, that the cam screw for

switch #1 is in location E. By changing that cam screw to location D, three additional revolutions of the yoke or shaft

will be required to actuate #1 switch. Moving the cam screw to holes C, B or A will add three revolutions for each

location moved, until 13 revolutions are required between switch #1 and 2 actuation.

3. The cam screw for switch #2 in location A. By moving it to location B, C, D, or E, three revolutions are added for

each location change.

4. Rotate the switch slowly through the full cycle several times before tightening the bolts securely. Observe the

rotation for signs of yoke or shaft misalignment or binding with the actuator shaft. Correct as necessary, then

tighten the mounting bolts and recheck alignment.