Dwyer MFD-1 User Manual

Proximity controls, Model fd fluidizer disk

PROXIMITY CONTROLS

Phone: 219/879-8000

www.dwyer-inst.com

A DIVISION OF DWYER INSTRUMENTS, INC.

Fax: 219/872-9057

e-mail: [email protected]

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

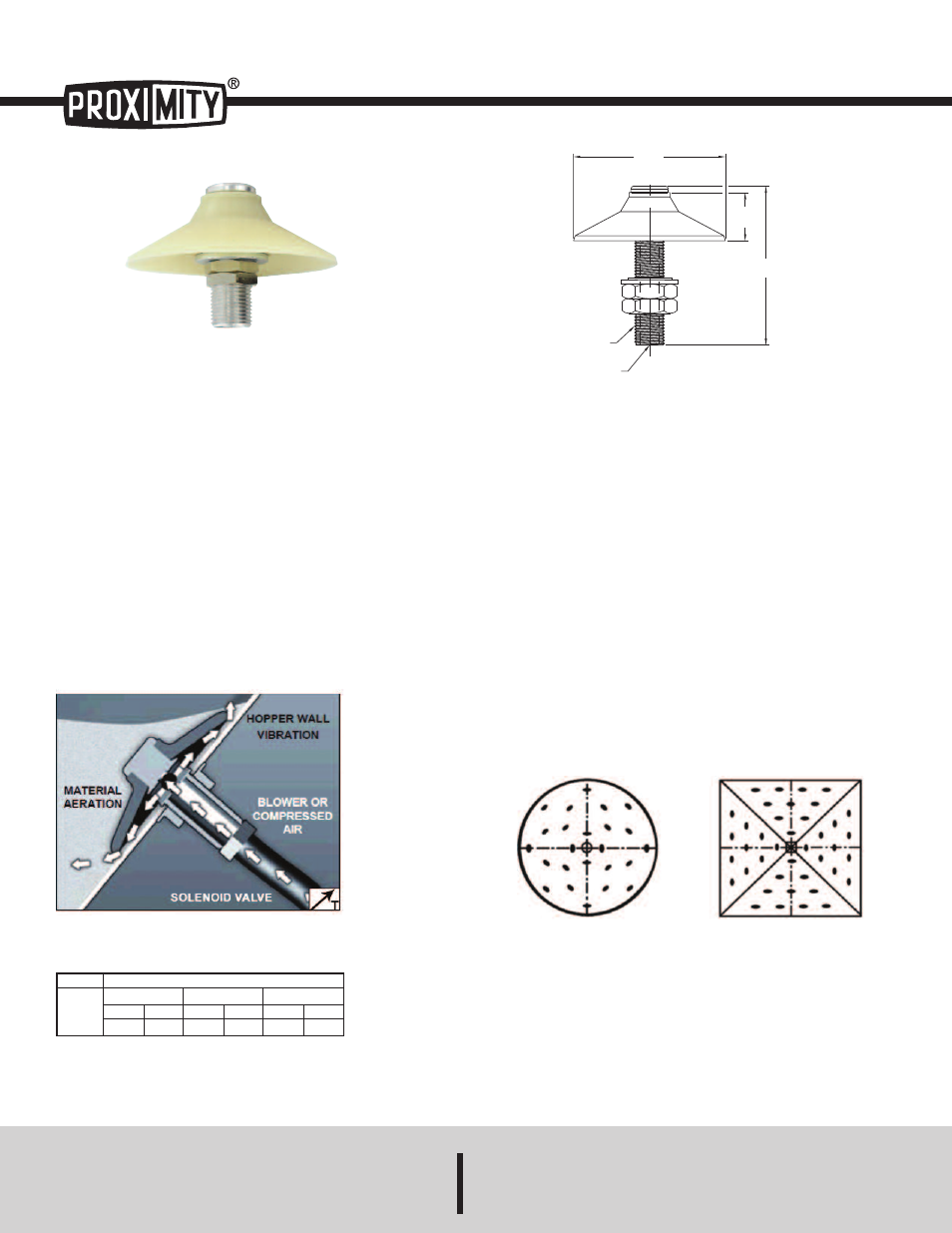

Model FD Fluidizer Disk

Bulletin F-FD

Specifications – Installation and Operating Instructions

The Model FD Fluidizer Disk combines aeration and vibration to solve the

most difficult bulk solid flow applications. The special design creates a vibration

as the air flows between the pads boot and bin wall. This provides a very

effective flow aid for all types of dry products. Plus the FD does not require

a specific air pressure for operation. Your pneumatic system pressure can

range from 29 to 87 psi.

HOW IT WORKS

Air is introduced in the silo or bin through the fluidizer disk. As the air discharges

in the material it provides aeration effect to fluidize the material. The positive

air pressure keeps the material from getting under the boot. The air flowing

under the boot causes it to vibrate. The vibration of the boot helps move

material that has a tendency to hang up or bridge. When the air is removed

from the boot, the pressure of the material and the design of the boot forces

the boot against the side of the bin. This prevents material from getting under

the boot and into the air supply line.

SPECIFICATIONS

Temperature Limits: -40 to 340°F (-40 to 170°C).

Air Supply: 29 to 87 psi (2 to 6 bar).

Air Consumption: See model chart.

Air Connection: 3/8˝ male BSP and 1/2˝ female BSP.

Material:

Disk: Silicon 50 SH (A) Elastosil (FDA approved);

Center Shaft: 304 SS;

Sealing Washer: EPDM;

Flat Washer: Galvanized steel;

Hexagonal Nuts: Nickel plated brass.

Weight: 7.9 oz.

Model

FD-1

Air Consumption

29 psi (2 bar) 58 psi (4 bar) 87 psi (6 bar)

LPM

100

CFM

3.53

LPM

150

CFM

5.29

LPM

250

CFM

8.82

INSTALLATION

To install the Fluidizer Disk, drill a 7/8˝ hole in the hopper, bin, silo, etc., wall

where material flow is a problem. From the inside, place the stainless steel

shaft and silicon disk assembly through the walls, from the outside, slip on

the sealing washer, flat washer and hexagonal nuts. Tighten down until snug.

The unique design of the Fluidizer Disk allows the pad to be mounted on

virtually any kind of surface, but for best results, try mounting on a clean and

smooth surface.

TYPICAL MOUNTING CONFIGURATION

MAINTENANCE

Upon final installation of the Model FD Fluidizer Disk, no routine maintenance

is required. A periodic check of the system is recommended. The Model FD

is not field serviceable and should be returned if repair is needed (field repair

should not be attempted and may void warranty). Be sure to include a brief

description of the problem plus any relevant application notes. Contact

customer service to receive a return good authorization number before

shipping.

©Copyright 2014 Dwyer Instruments, Inc.

Printed in U.S.A. 5/14

FR# R6-443810-00 Rev. 1

4-3/32

[104.0]

1-19/64

[33.0]

4-19/64

[109.0]

1/2˝ BSP

3/8˝ BSP

Silo cutaway showing FD in use.