Dwyer Mark User Manual

Page 11

10

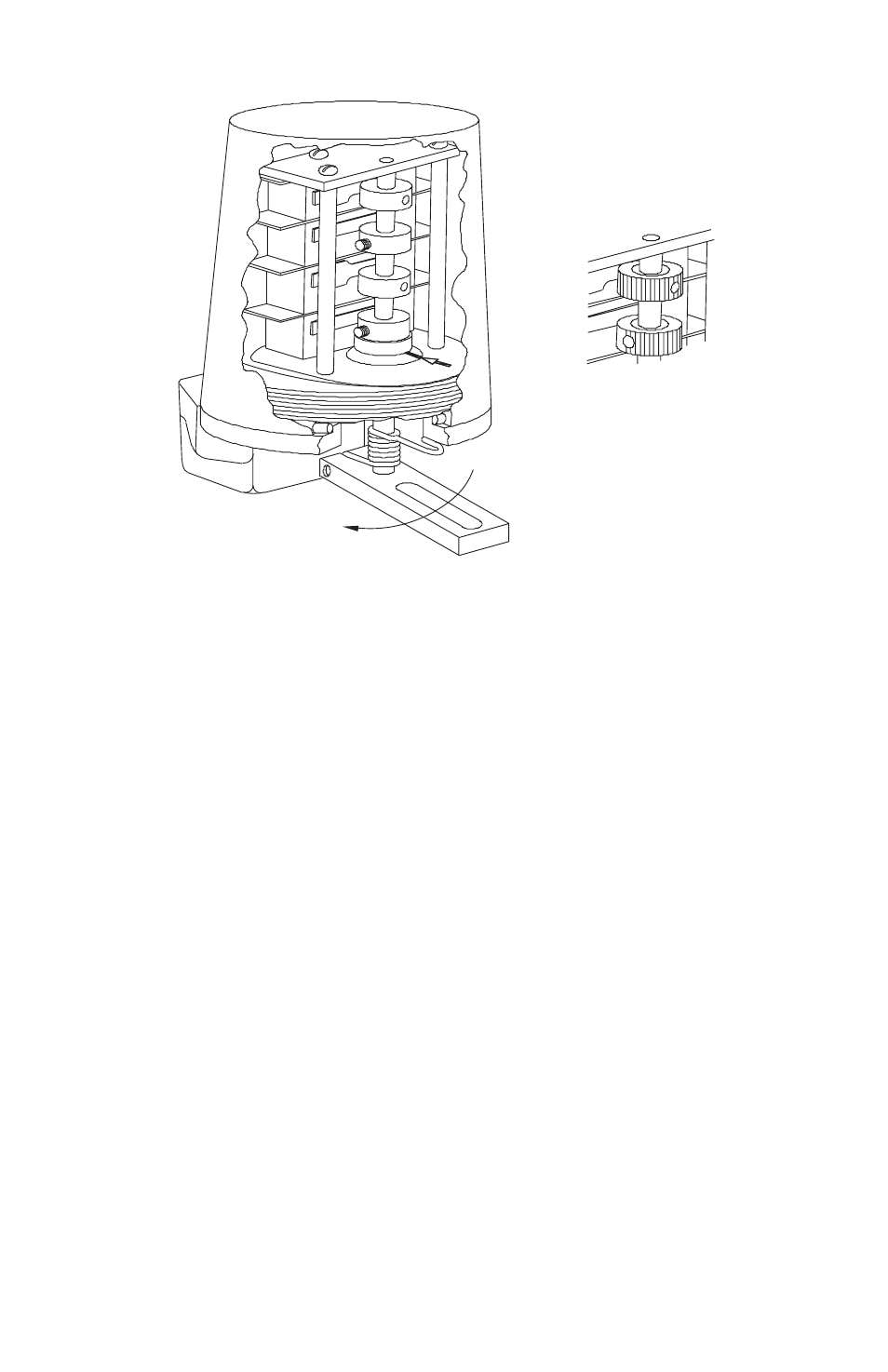

MARK 1 AND 4 LEVER DRIVE INSTALLATION

1

2

3

4

3

4

CLOCKWISE

INSTALLATION PROCEDURE

1. Attach proper mounting bracket to switch housing using screws provided. Tubular spacers are provided for some

installations.

2. Attach appropriate driving lever onto shaft. Do not tighten.

3. Attach switch and bracket to actuator, making sure that lever is free to rotate over entire range of actuator stroke.

4. Attach driving pin or bolt through lever arm if slotted, or on driving side of solid lever. (It may be necessary to loosen

or remove mounting bracket to accomplish connection on some actuators.)

5. Operate actuator very slowly and observe movement of all pins and levers to be sure there are no interferences.

Slide lever up or down on switch shaft to most desirable position. When all motions are made and clearances are

adequate, tighten clamp screw on lever that was left loose in step 2. Tighten all mounting screws. Recheck the

travel of all levers and pins for proper clearance through the entire stroke of the actuator.

6. Unscrew cover. Keep threads clean and free from damage. Index marks are imprinted into driven magnet collar as

shown (Mark 1 only). Set screws or holes in manual cams (#2, 4 and 6) will be directly above index marks on those

switches that are Closed. Marks must be in line when making switch cam adjustments. Cams are set at factory

when in the counterclockwise position, as shown, and listed as follows:

2 Switch Unit

#1 Open

#2 Closed

4 Switch Unit

#1, 3 Open

#2, 4 Closed

6 Switch Unit

#1, 3, 5 Open

#2, 4, 6 Closed

90º travel in clockwise direction will reverse all of above switch positions.