Dwyer BFM User Manual

Page 4

SENSOR LOCATION:

TO ENHANCE SENSITIVY INSTALL THE SENSOR

WHERE THE FLOW IS MOST TURBULENT OR WHERE

MATERIAL IMPACTS THE PIPE WALL.

THE FOLLOWING POINTS ARE IDEAL (FIG 8):

• Pipe elbow

• Point where material drops into spouting or chutes

• Point where material drops from conveyor onto the chute

BE SURE SENSOR STUD

IS MAKING A GOOD

TIGHT CONTACT WITH

MOUNTING SURFACE.

STUD SENSOR

INPUT

PUMP

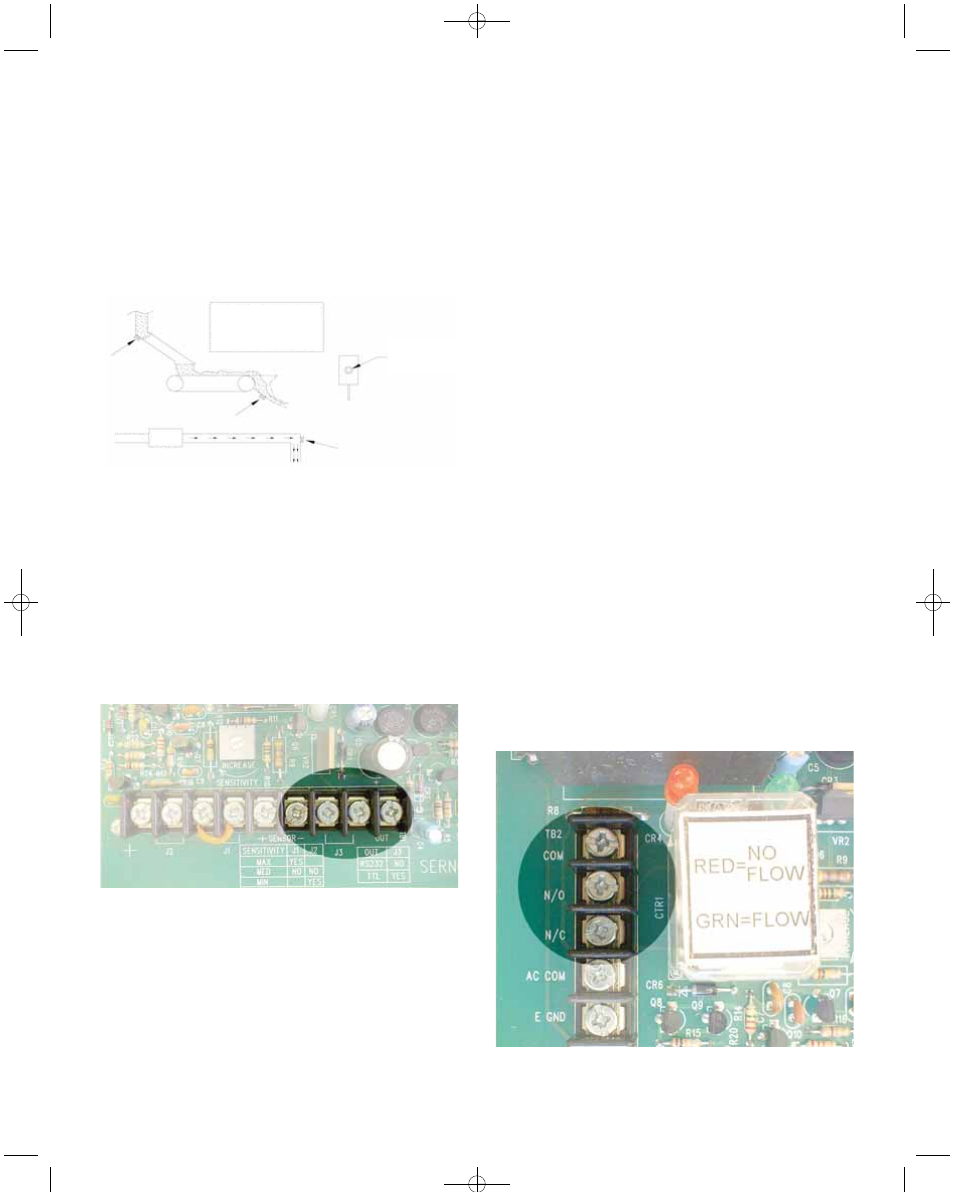

LOW LEVEL (LOGIC) OUTPUT WIRING

Low level outputs available (Fig. 9):

• TTL logic output

• RS232 logic output

TTL LOGIC OUTPUT:

The TTL Logic output is a 5VDC output.

To obtain a TTL Logic Output install jumper J3 as indicated

on the BFM PCB. Connect logic level output wiring to the

“Out” (+5V) terminal and the Sensor “-” (0V) terminals on TB1.

• NO FLOW: Red LED lights and 0VDC will be present at the

“OUT” terminal.

• FLOW: Green LED will light and 5VDC will be present at the

“OUT” terminal.

RS232 LOGIC OUTPUT:

The RS232 output is an industry standard 5VDC minimum

into 3K load. To obtain an RS232 logical output do not install

jumper J3 as indicated on BFM PCB.

• NO FLOW: Red LED lights and 0 VDC will be present at the

"OUT" terminal.

• FLOW: Green LED will light and 5VDC min. will be present

at the "OUT" terminal.

NOTE: For proper logic input to your computer, consult your

computer manual for the correct pin configuration for RS232

or TTL.

RELAY OUTPUT WIRING

Relay (CTR1) Contact Specifications:

• 4 amp at 125 or 250 VAC

• 1/10 HP at 125 or 250 VAC

• 3 amp at 30 VDC

Relay Output Wiring on TB2 (Fig. 10):

• COM = Common contact

• N/C = Normally closed

• N/O = Normally open

Figure 8

Figure 9

Figure 10

FL-1-BFM:TEMPLATE 12/4/08 10:59 AM Page 4