Dwyer BFM User Manual

Page 3

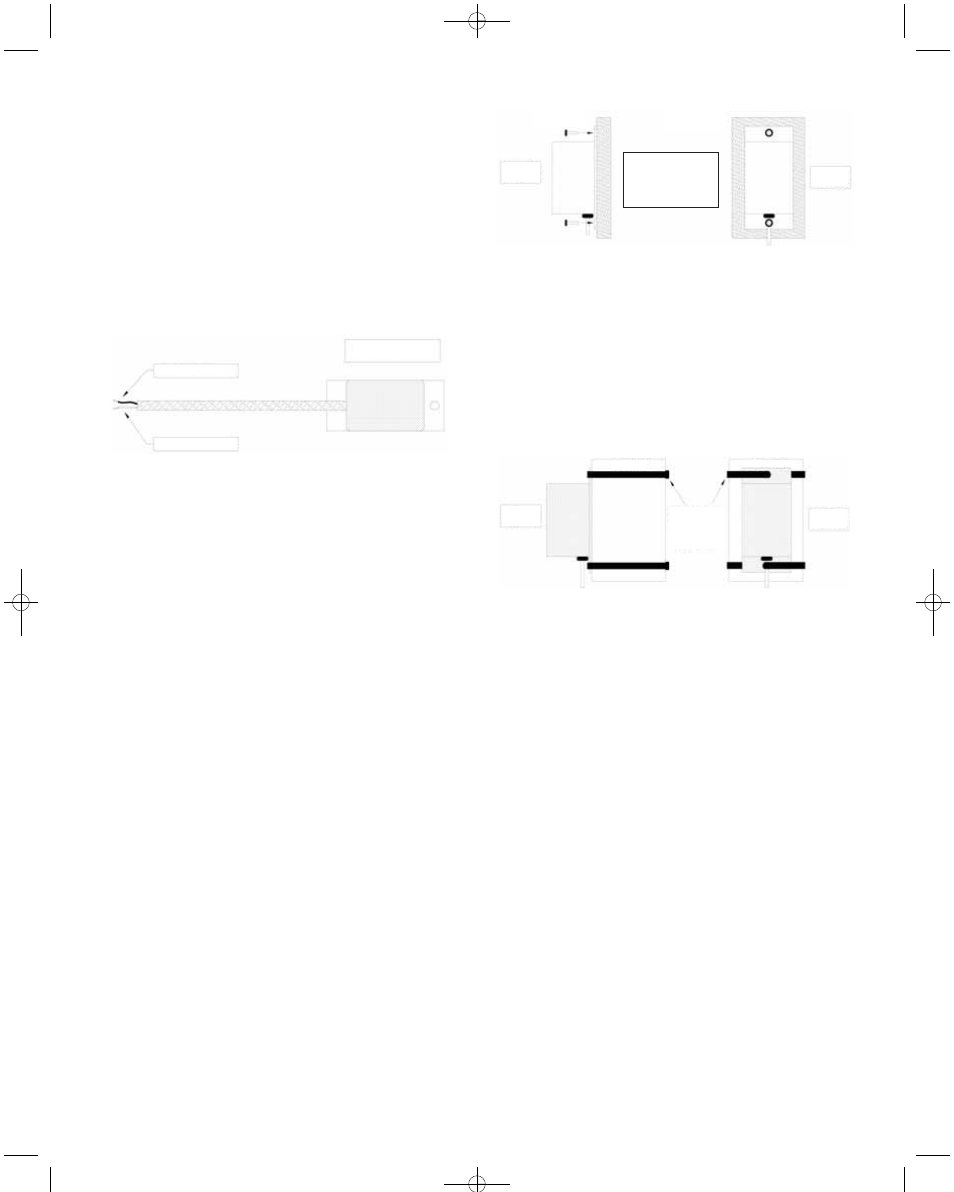

BLACK LEAD

RED/WHITE LEAD

BFM SENSOR

RELAY AND LOW LEVEL LOGIC WIRING

See those sections later in this manual.

SENSOR INSTALLATION

The BFS-1 sensor is in very a rugged polymer housing with a

sealed 6´ cable pigtail (Fig. 5):

• Red/Black = Positive

• White/Black = Negative (this is electrically connected to the

metal sensor stud)

SIDE VIEW

FRONT VIEW

BFM

SENSOR

BFM

SENSOR

NOTE: PILOT HOLES

ARE DRILLED INTO

FLAT SURFACE AND

MOUNTED WITH

PORPER HARDWARE.

MOUNTING PROCEDURES FOR SENSOR:

The BFS-1 Sensor can be screwed, clamped or strapped in

place and is able to detect flow through most sheet metal.

• Clean the surface area where the sensor is to be installed.

The surface should not have any buildup or scale but does

be perfectly clean.

• The sensor stud located at the bottom of the sensor

housing must make solid contact with the surface of the

pipe to be monitored.

MOUNTING TO A FLAT SURFACE:

Refer to the mounting holes located at each end of sensor

housing (Fig. 6).

• Mark mounting holes.

• Drill pilot holes for mounting screws.

• Screw sensor housing to flat surface.

MOUNTING TO A ROUND OR NON-FLAT SURFACE:

(FIG. 7)

• Using strapping (such as heavy duty wire-ties) or clamps to

secure the sensor housing to the pipe so the metal sensing

stud makes firm contact with the surface.

BFM

SENSOR

BFM

SENSOR

SIDE VIEW

FRONT VIEW

NOTE: STRAPS

OR CLAMPS

ARE USED FOR

MOUNTING TO

NON-FLAT

SURFACE

Figure 5

Figure 6

Figure 7

FL-1-BFM:TEMPLATE 12/4/08 10:59 AM Page 3