Dwyer IEFS User Manual

Page 7

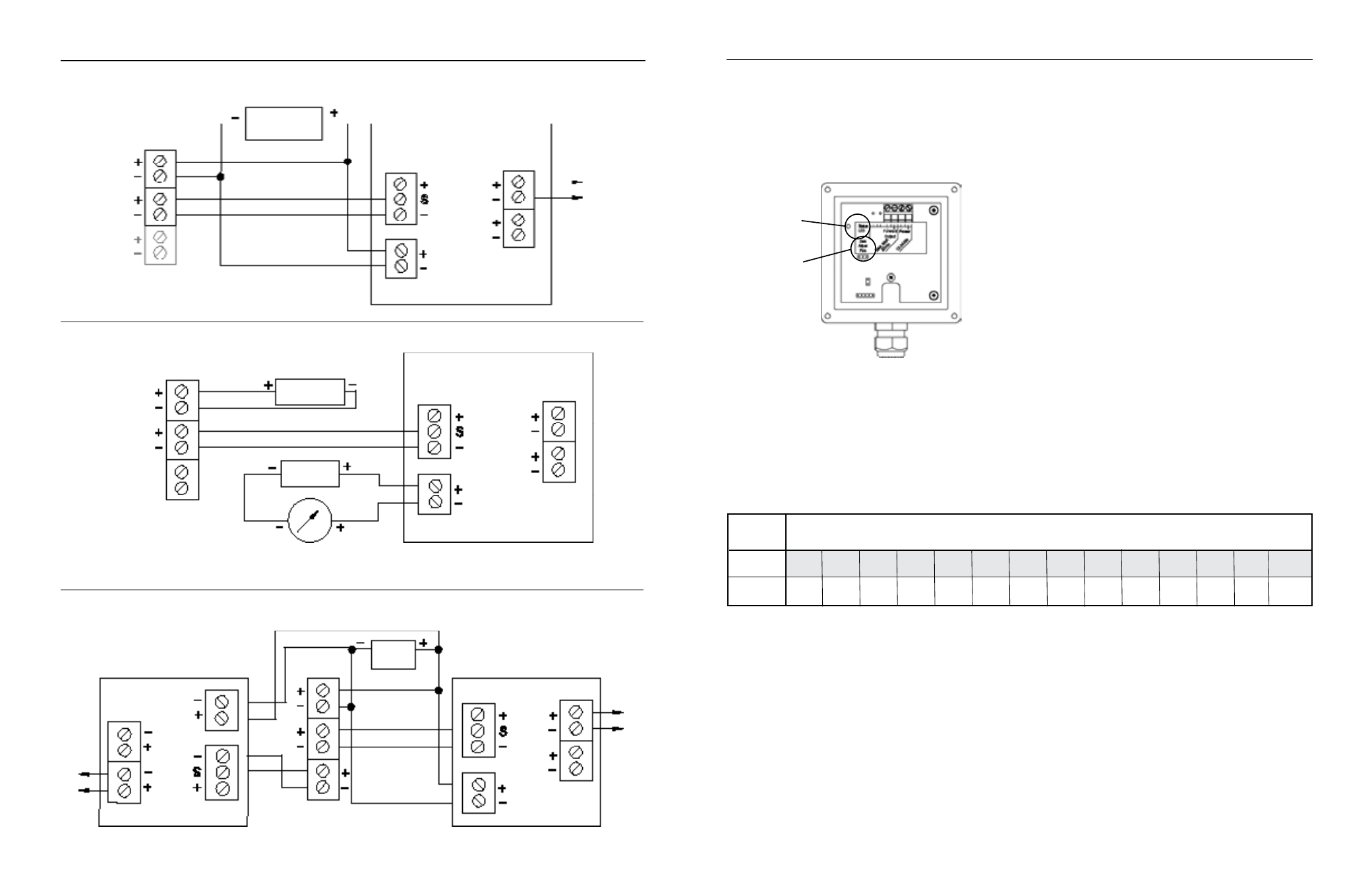

CONNECTIONS DIAGRAMS

SERIES RTI DISPLAy AND PROPORTIONAL FEED

Sensor

Input

Power

Forward Output

SERIES IEFS

24 VDC Power

Power

4 to 20mA

Pulse

Scaled

Pulse

Pass-Thru

To

Proportional

Feed

Metering

Pump

SERIES RTI DISPLAy AND 4 to 20 mA OuTPuT

SERIES RTI

*See Dual RTI Diagram for an

example of bidirectional connections.

*See Dual RTI Diagram for an

example of bidirectional connections.

Page 10

Page 11

Reverse Output

(-RFO only)

IEFS SERIES

DuAL SERIES RTI DISPLAyS

(Example of bidirectional Connection)

Power

Forward Output

Sensor

Input

24 VC

Power

Power 4 to 20mA

Pulse

Scaled

Pulse

Pass-Thru

SERIES RTI

SERIES RTI

Sensor

Input

Power 4 to 20mA

Pulse

Scaled

Pulse

Pass-Thru

Reverse Output

(-RFO only)

Reverse Output

(-RFO only)

Power

Forward Output

SERIES IEFS

4 to 20 mA Device

(e.g. pump, PLC)

24 VDC

Power

Sensor

Input

Power

4 to 20mA

Pulse

Scaled

Pulse

Pass-Thru

SERIES RTI

24 VD-

CPower

Min 0.28

Max 20.0

FLOW RATES (IN GALLONS PER MINuTE)

Feet Per

Second

NOMINAL PIPE SIzE

3” 4” 6” 8” 10” 12” 14” 16” 18” 20” 24” 30” 36” 48”

6

11

25

44

69

99

134

175

222

274

395

617

888

1580

440

783

1,762

3,133

4,895

7,050 9,596 12,533 15,863 19,584 28,200 44,064 63,452 112,804

OPERATION & MAINTENANCE

Minimum Flow.

As with any other flow sensor, there is a

rate below which the IEFS Series sensor cannot read. Check

the table below for the minimum flow rate detectable by the

sensor for a given pipe size.

Presence of Flow Indication.

To assist in troubleshooting, the

“Status LED” has two blinking modes in normal operation.

When there is no flow detectable by the meter (below

minimum threshold), the LED blinks every 8.0 seconds. When

there is detectable flow, the same indicator blinks every 3.0

seconds (Pulses are being output when indicator is blinking

every 3 seconds).

Filtering.

The software of the IEFS Series filters out electrical

noise and averages sudden variations in the flow to smooth

the output. It takes a matter of seconds for the flow sensor to

get up to full output when it is powered up or when flow begins.

Electrode Coating.

Grease or other adhering, non-conductive

materials can stop flow detection if the electrodes become

heavily coated. To clean the electrodes, remove the sensor

from the pipe and gently scrub the electrodes (three silver

bumps) on the reading face of the flow sensor. A mild soap

(dishwashing liquid for example) can be used to aid the

cleaning process.

To perform the adjustment, after determining that there is a

full pipe with no flow, short between the two pins marked “Zero

Adjust”. A red LED light will come on for approximately 50

seconds and then go out. The zero adjustment is completed.

zero Adjustment.

When the Series IEFS meter is powered up

and there is no flow, there should be no output pulses (or, if

connected to the RTI, flow rate should read “0”). If there are

pulses, it may be necessary to adjust the flow meter under no-

flow conditions after it has been installed. This should only be

done if the indicated flow is low, near the lower cutoff.

zero

Adjust

Pins

Status

LED