Warranty/return – Dwyer IPFS User Manual

Page 6

rePAir & PArTs

signal

The flow sensor has only one moving part, the rotor. If this is

turning properly and there is no signal, the Hall-effect sensor is

not operating properly. To check the signal, apply 12 Vdc regu-

lated* power to the red (+) and black (-) leads. Set a multimeter

to voltage reading. Put the positive multimeter lead on the red

wire and the negative lead on the white wire. Slowly turn the

rotor. Voltage reading should swing between +12 Volts and 0

Volts as the rotor turns. If it does not, the Hall effect sensor

is not working properly. Checking for continuity is not a useful

test of these sensors.

*NOTe: An unregulated power supply can exceed max voltage of micro

powered sensor (gray cable) and damage sensor.

.

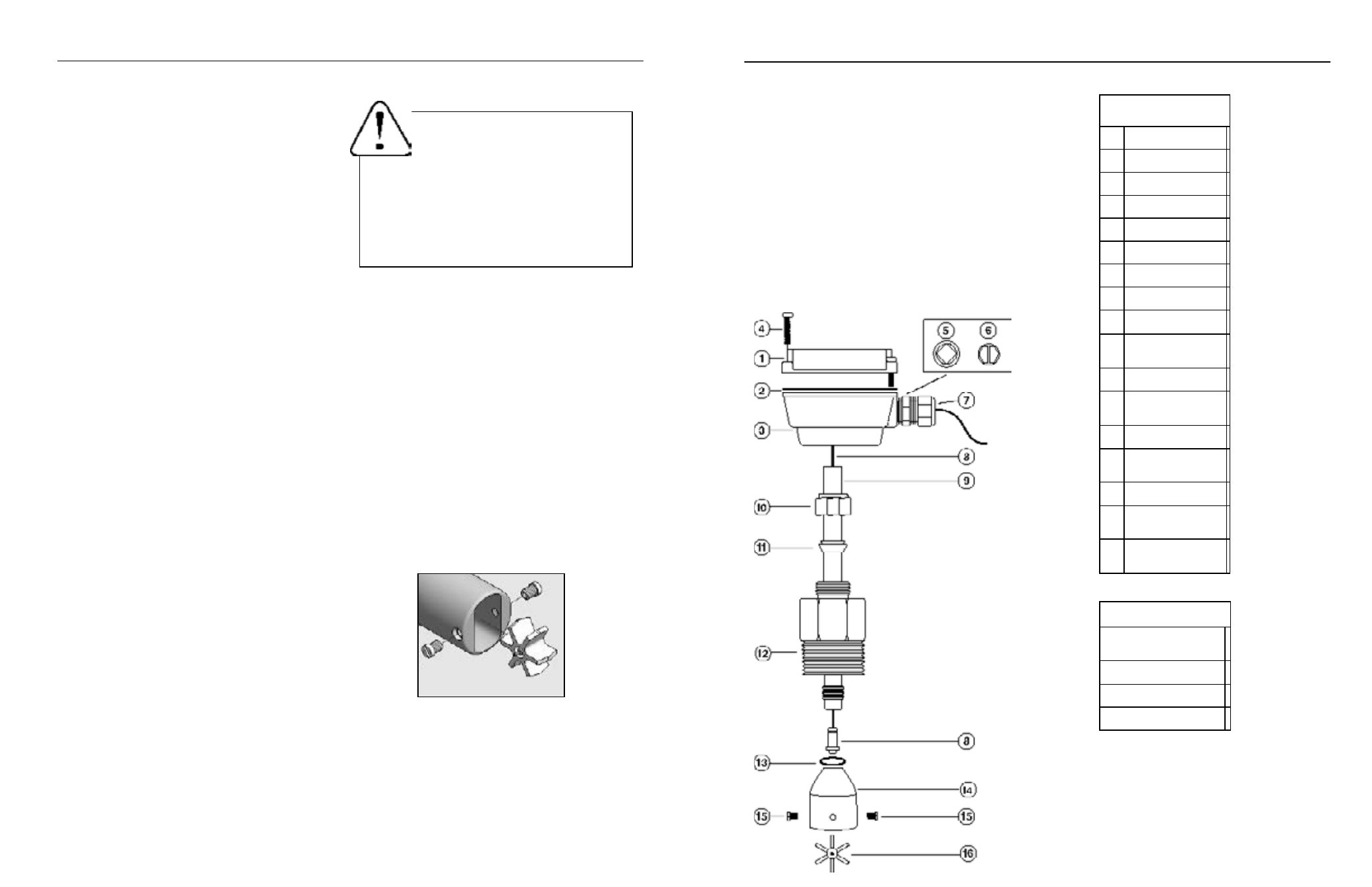

IPFS-0XX Parts

1

Upper housing assembly

2

Gasket

3

Lower housing

4

Housing screw (4 req'd)

5

Plug, steel

6

Plug, plastic

7

Strain relief

8

Pickup, Standard (for RTI)

9

Tube

10

Compression nut

11

Compression ferrule

12

Adapter fitting

13

Rotor housing O-ring (EPDM)

14

Rotor housing

15

Jewel bearings (2 req)

16

Rotor with shaft

17

Rotor repair kit

(includes of #15 & #16)

Page 8

Parts explosion

IPFS-1XX (HOT-TAP) Parts (not shown)

Adapter fitting

Ball valve assembly

Collar, locking

Hex nipple, 2"

Page 9

rotor replacement.

Rotors are easily field-replaced. Shaft

and rotor are a single unit, and are not replaced separately.

If replacement is due only to normal shaft wear, bearing re-

placement is probably not necessary. If the rotor has been

damaged by impact, the bearings should also be replaced.

Rotor and bearings can be ordered as a kit. Follow these

steps:

1. Unscrew the threaded bearing housings to expose

the shaft ends. If bearings are being replaced,

back them completely out.

2. Remove the rotor. Put the new rotor in its place.

3. Thread in one bearing housing part way, then the

other. Take care to start the end of the shaft into

the bearing hole before tightening further.

4. Screw in bearing housings until they bottom.

Note

: Do not use excessive force.

5. Check for free spin. Blowing lightly on the rotor

should result in it spinning rapidly and coasting to

a smooth stop.

rePAir

caution!

Never attempt to remove a flow

sensor when there is pressure in the pipe

unless it is specifically designed for hot

tap installation and removal. Loosen the

compression nut slowly to release any trapped pres-

sure. If fluid sprays out when removing the sensor,

stop turning and depressurize the pipe. Failure to

do so could result in the sensor being thrown from

the pipe, resulting in damage or serious injury.

OPerATiON

Theory.

In principle, an insertion flow sensor measures the

velocity of flow at one point in the pipe, and flow rate and total

can be inferred from this one point. Accuracy is decreased

by any factor which makes the flow at the measured point

unrepresentative of the entire flow stream. This includes

distorted flow patterns caused by upstream fittings too close

to the sensor. The worst offenders are fittings that increase

the flow on one side of the pipe, such as partially-opened

gate or butterfly valves. Fluid moving in a pipe does not all

flow at the same velocity. Toward the center of the pipe,

fluid moves faster than at the wall, and the relationship be-

tween the two changes as overall flow rate increases. This

change in the “velocity profile” can result in non-linearity,

which means that the K-factor that is correct for one flow

rate may be incorrect for another. The recommended depth

settings have been carefully chosen to minimize this source

of error, and should be followed carefully, especially in the

smaller pipe sizes.

Flow range.

These sensors are designed to operate at flow

velocities of 0.3 to 30 feet per second. If erratic readings

are encountered at low flows, check the chart to see if flow

is below minimum for the pipe size. The standard shaft and

bearings should have a long life at continuous high flow.

OPerATiON & rePAir

Refer to "Terms and Conditions of Sale" in our catalog or on

our website. Contact customer service to receive a Returns

Goods Authorization number before shipping your product

back for repair. Be sure to include a brief description of the

problem plus any relevant applciation notes.

WArrANTY/reTUrN