Dwyer IPFS User Manual

Page 2

TABLe OF cONTeNTs

General information

General Information, Features, Specifications ................................................................................................. Page 1

installation

Piping, Positioning the Meter, Immersion, Depth Setting ................................................................................ Page 2

IPFS-0 Installation, IPFS-1 Installation ............................................................................................................. Page 3

Dimension C, Pipe Wall Thickness .................................................................................................................... Page 4

Flow Rate ............................................................................................................................................................ Page 4

Straight Pipe Recommendations ...................................................................................................................... Page 5

Full Pipe Recommendations .............................................................................................................................. Page 6

connection

Calibration .......................................................................................................................................................... Page 7

Operation & repair

Theory of Operation, Flow Range, Rotor Replacement .................................................................................... Page 8

repair & Parts

Signal, Parts Explosion, Parts List .................................................................................................................... Page 9

Troubleshooting

Problem, Probable Cause, To Try....................................................................................................................... Back

TABLes AND DiAGrAMs

Features .............................................................................................................................................................. Page 1

Specifications Table ........................................................................................................................................... Page 1

Piping .................................................................................................................................................................. Page 2

Positioning the Meter ......................................................................................................................................... Page 2

Depth Setting ..................................................................................................................................................... Page 2

Meter Installation ............................................................................................................................................... Page 3

Table 1 (Dimension 'C') ...................................................................................................................................... Page 4

Table 2 (Pipe Wall Thickness) ............................................................................................................................ Page 4

Straight Pipe Recommendations ...................................................................................................................... Page 5

Full Pipe Recommendations .............................................................................................................................. Page 6

Connection Diagram .......................................................................................................................................... Page 7

K factor

................................................................................................................................................................ Page 7

Rotor Replacement ............................................................................................................................................ Page 8

Parts Explosion ................................................................................................................................................... Page 9

Parts List ............................................................................................................................................................. Page 9

Troubleshooting: Problem, Probable Cause, To Try .......................................................................................... Back

Page 1

GeNerAL iNFOrMATiON

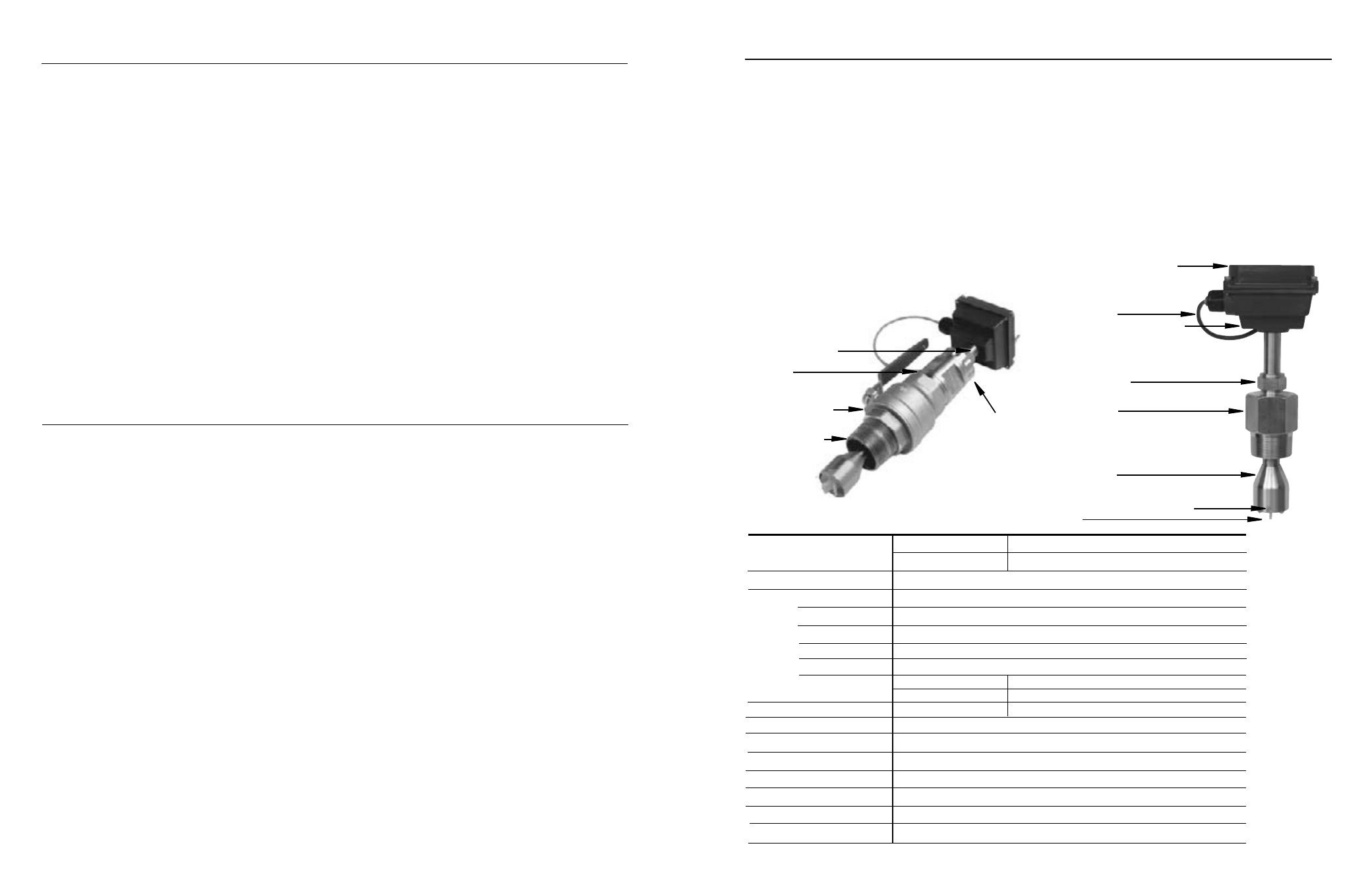

FeATUres

Adapter fitting with

2” NPT threads

Full-port 2” ball valve

for sensor removal

2” Adapter

removes to mount

hot-tap machine

3/4” diameter tubing

for low insertion force

iPFs-1XX

Rotor

Rugged cast aluminum housing

18 Foot Cable

Modular electronics (optional)

• rate/total/pulse/4-20 mA

• blind 4-20 transmitter

• pulse divider

Compression nut

for easy adjustment, secure locking

Adapter fitting

with 1-1/2” male NPT threads

Rotor housing

Removable jewel bearings for

exceptional low flow performance

iPFs-0XX

sPeciFicATiONs*

GeNerAL iNFOrMATiON

The IPFS Series are adjustable depth insertion paddlewheels

that come in brass or 316 stainless models to fit 3” to 40” pipe.

Installation fittings are standard 1-1/2" or 2” NPT. Fittings such

as saddles and weldolets may be purchased either locally or from

Dwyer Instruments Inc.

Ruby bearings and a non-drag Hall-effect sensor give these meters

the widest flow range of any of the paddlewheel types. A sensor

detects the passage of miniature magnets in the six rotor blades.

The resulting square-wave signal can be sent for hundreds of

feet over unshielded cable without a transmitter and connected

directly to many PLC’s and other controls without any additional

electronics.

If desired, a modular system of electronics can be installed

directly on the flow sensor or mounted remotely. The Series RTI

provides digital rate and total display, as well as programmable

pulse output; the Series RTI also provides a 4 to 20 mA analog

output. The Series BAT is a blind analog transmitter. Program-

mable pulse for pump pacing is available with the Series PWD.

The “hot-tap” models IPFS-1 can be installed or serviced without

shutting down the line by means of a 2” full-port isolation valve

that comes with a nipple for installation on the pipe fitting. In most

circumstances, no special tool is required.

Locking collar

s-size

L-size

3” to 12” (50 - 300mm)

12” to 40” (300 - 1000mm)

Hall Effect sensor, 12 Vdc current sinking pulse

Cast aluminum

Brass or 316 SS

PVDF

Nickel-bound tungsten carbide (zirconia ceramic optional)

Ruby jewel

iPFs-0

iPFs-1

None

Bronze (316SS optional)

1.5” NPT

2” NPT

0.3 - 30 feet/sec (0.1 - 9 meter/sec)

+/- 1.5% of full scale

200˚ F (93˚ C)

200 psi (14 bar)

0.44 x pressure in pipe

5-24 Vdc, 1.5 mA

#22 AWG 3-con, 18’ (6m); 2,000’ (650m) maximum cable run

Pipe size

sensor

Materials Housing

sensor Body

rotor

shaft

Bearings

isolation Valve

Fitting size

Flow range

Accuracy

Maximum Temperature

Maximum Pressure

insertion Force

Power

cable

*Specifications subject to change.