Maintenance, General safety information, Continued) – Blue Angel Pumps BCAPSE50ODS User Manual

Page 3

3

www.blueangelpumps.com

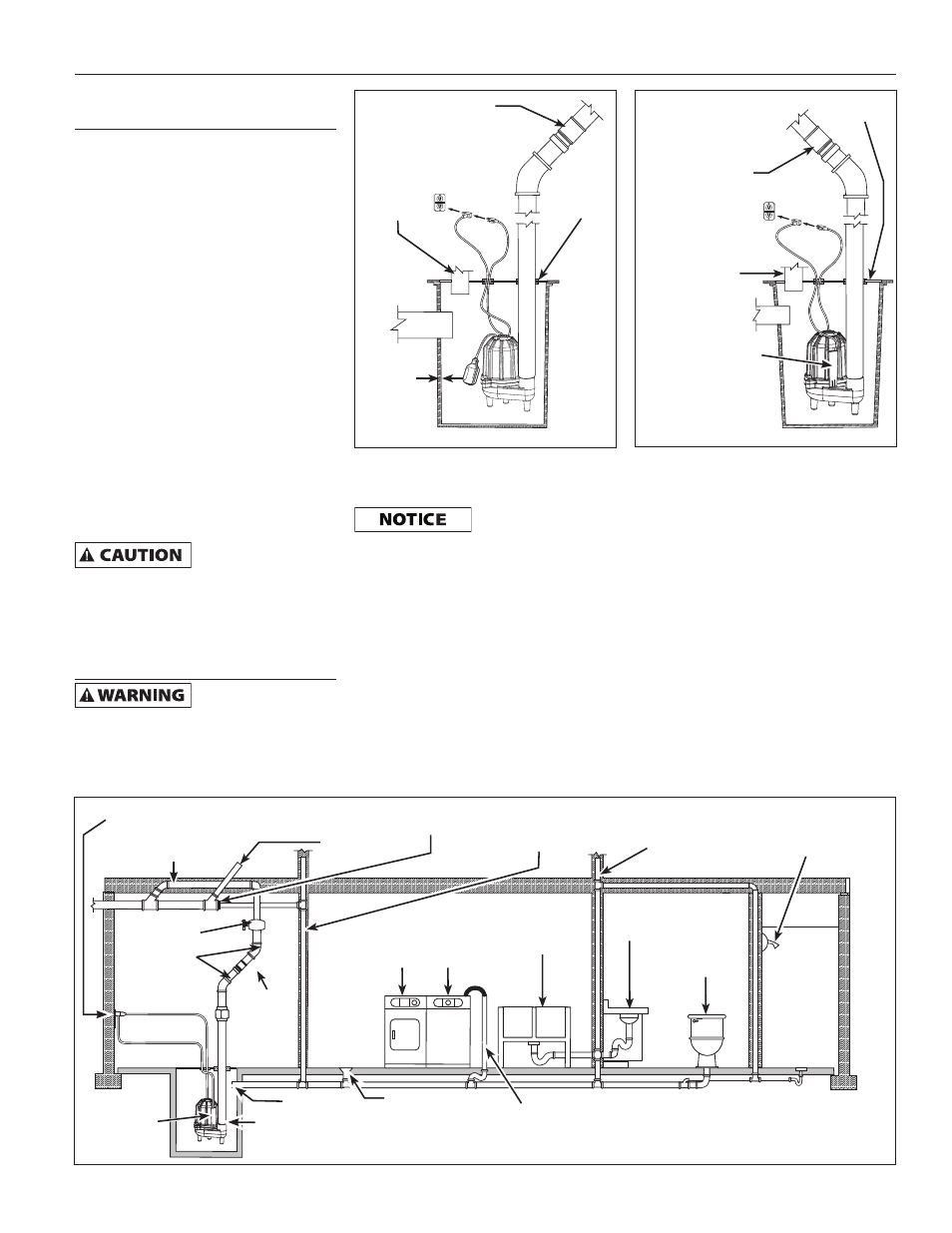

6. BCSE50T models are supplied with

a detachable tether switch with a

piggyback plug (see figure 3A). The

length of the tether (distance of cord

from float to clamp) should not be set

shorter than 3-1/4 inches and should

not be used in a basin smaller than 14

inches in diameter. If using a differential

other than the factory setting, be sure

when the pump shuts off at least 4

inch of fluid is left in the basin so the

impeller remains submerged.

7. BCAPSE50 models are supplied with

an capacitive water sensor. Orient the

pump in the basin so that the water

sensor is 180° away from the inlet.

Make certain the incoming water

stream does not hit the capacitive

surface (See Figure 3B).

8. When a tether switch is used, rigid

dis charge pipe is required. If the

pump is allowed to move, the

tether switch could be re strict ed

by the basin wall, pre vent ing the

pump from operating.

Before removing

pump from basin

for service, always disconnect electrical

power to pump and control switch. For

any work on pump or switch, ALWAYS

unplug the power cord. Do not just turn

off circuit break er or unscrew fuse.

Maintenance

Make certain that

the pump is

unplugged before attempting to service

or remove any component. This pump is

assembled in the factory using special

equipment; therefore only authorized

service dealers or qualified electricians

should attempt to repair this unit.

Improper repair can cause an electrical

shock hazard.

The pump contains

oil that may be

under pressure because of heat. Let the

pump cool for a minimum of two hours

before servicing this unit.

1. Disassembly of the motor prior to

expiration of war ran ty will void the

warranty. It might also cause internal

leakage and damage to the unit. If

repairs are required, return the pump

to the dealer from whom it was

pur chased or call 1-888-636-6628. If

motor is ever disassembled the o-rings

must be replaced. Care must be taken

to ensure that all seals do not leak.

2. After the basin cover is removed

and necessary dis charge piping

disconnected, lift pump from basin.

3. Pump should be checked on a

regular basis for proper op er a-

tion. If anything has changed since

unit was new, the unit should be

removed and repaired or replaced.

Only qualified electricians or service

peo ple should at tempt to repair

this unit. Improper repair and/or

assembly can cause an electrical

shock hazard.

4. Place the pump in a suitable area

where it can be cleaned thoroughly.

Remove all scale and deposits on pump.

5. Submerge the complete pump in a

disinfectant so lu tion (10% chlorine

bleach solution) for at least one

hour before handling the pump.

Check valve 45º

Vent

Inlet

Gasket

1/2 inch

Min.

Clearance

Basin

figure 3A - Prefabricated Basins

Check

valve 45º

Vent

Inlet

Gasket

*Orient the pump so that

the switch is 180° away

from the inlet. Make sure

the incoming water stream

does not hit the switch

surface.

Basin

figure 3B - Prefabricated Basins

figure 2 - Typical Installation

Upper level

drainage

Float

switch

2 inch

Check

Valve

45º Elbow

Washer

Dryer

Floor drain

Washer drain

Flange

Cleanout

Laundry tubs

Lavatory

Shower

Toilet

Vent pipe

Vent pipe

Sewage pump passes

2 inch dia. solids

Three prong grounded outlet equipped

with a ground fault interruptor

2 inch

Gate Valve

2 inch Discharge pipe

General Safety

Information

(continued)

BCSE50T, BCSE50M

BCAPSE50 and BCAPSE50-2