Maintenance – Blue Angel Pumps 63042-BLA1 User Manual

Page 4

4

Operating Instructions

2 HP Grinder Pumps

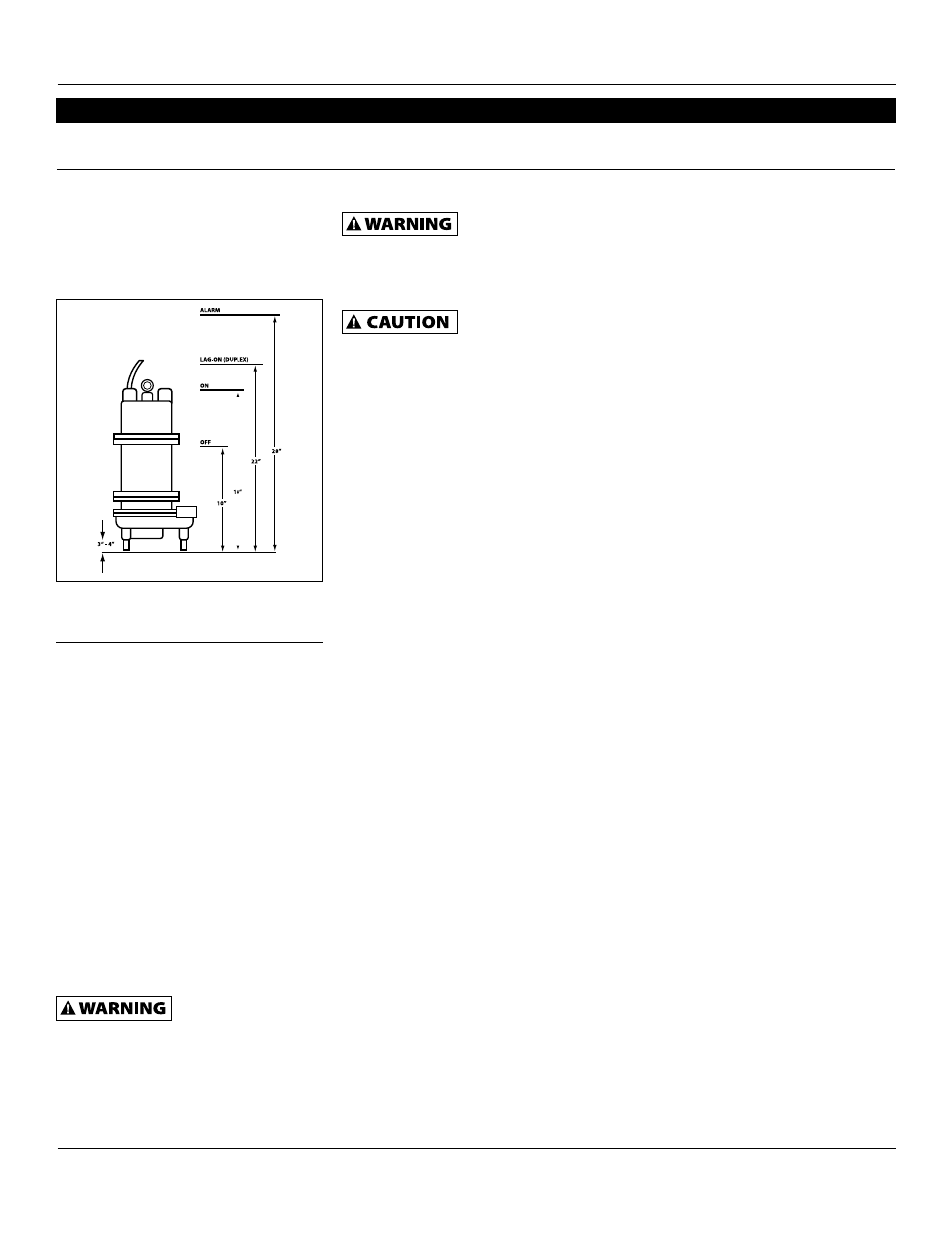

Note: If pump is not mounted on a

lift-out rail system, the leg kit needs

to be installed. Set leg height so a 3”

– 4” clearance is achieved between the

bottom pump inlet and basin bottom.

Maintenance

Only qualified mechanics with proper

tools and knowledge should attempt to

service this pump.

REPlAcING GRINDER IMPEllER AND

sHREDDING RING

Note: This is the only disassembly

operation permitted in the field. All

other repairs must be performed at an

authorized service center or the factory.

standard Tools Required:

• Standard socket wrench set

• Standard set of open-end

wrenches

• Hammer

• Vise grip pliers

• Allen head socket set

• Screwdrivers

• Wire brush

Disconnect all power

and control wires to

motor at the control panel before starting

the disassembly operations. Do not rely

upon opening the circuit breaker only.

Hazardous cutter.

Rotation of the cutter

with hands in the cutter area can cause

loss of fingers. Keep hands away from

the pump inlet opening when working

on or handling the pump for any reason.

Pump should be

sanitized with bleach

before starting work.

• Pump should be thoroughly

cleaned of trash and deposits

before starting disassembly

operations.

• Wear protective gloves and

clothing.

• Always use a rag on the impeller

when turning to prevent cutting

hands on the sharp edges of the

shredding ring.

DIsAssEMbly oF sHREDDING RING

AND GRINDER IMPEllER

1. Remove 3 bolts from grinder ring

flange with socket wrench. The

grinder ring is pressed into the

flange for convenient removal.

2. Thread 2 of the bolts (removed from

the grinder ring flange) into the

tapped back-off holes in the flange

and evenly tighten the bolts to back

the grinding ring out of the pump

housing.

3. Hold the grinder impeller by prying

against the impeller cutting bar and

remove the cap screw from the end

of the shaft.

4. Use a large screwdriver to the slot

of the shaft and tap on the cutter

vane with a hammer. Tap in a

counterclockwise direction (thread is

right-hand).

5. If the impeller removes easily, clean

and replace if worn.

6. Make sure the pump impeller has

not loosened when the grinder

impeller was removed. This can be

checked on reassembly of grinder

impeller and shredding ring. The

tips of the impeller cutter vanes

should extend 1/8” below the

bottom of the shredding ring. If

the distance is greater, the pump

impeller has loosened. If the

distance is less, shredding ring is not

properly seated.

7. After the volute case has been

removed, wrap emery cloth around

the shaft and hold with vise grip

pliers. Us a cloth on the impeller and

thread tight against shoulder on

shaft.

8. Clean all threads with a wire

brush and file smooth any nicked

threads. Apply an anti-seize or other

graphite compound on threads

before replacing grinder impeller.

9. Make sure cap screw in bottom of

pump shaft is tight. Hold impeller

with screwdriver between the cutter

bar and teeth of shredding ring

while tightening the cap screw.

10. Make sure the impeller turns freely

by hand after reassembly. Some

drag will be present due to the

shaft seals. There should not be any

binding or tight spots when turning

the grinder impeller.

11. If there is any rub or drag on the

shredding ring, loosen the 3 bolts

in the shredding ring plate and

tap lightly with the hammer to

loosen. Retighten the bolts. Be

sure to tighten the bolts evenly,

applying pressure on all 3 bolts. DO

NOT COMPLETELY TIGHTEN ONE

BOLT BEFORE TIGHTENING THE

OTHER BOLTS. THIS WILL CAUSE

MISALIGNMENT AND LOCKING OF

SHREDDING RING AND GRINDER

IMPELLER.

HP

Voltage

Phase

breaker size

Heater size

2

230

3

20 Amp

K-50

2

460

3

15 Amp

K-33

chart 3

www.waynewatersystems.com

Figure 3 - leg Kit