Control panel and level sensing, 2 hp grinder pumps, 3operating instructions – Blue Angel Pumps 63042-BLA1 User Manual

Page 3: Chart 2

3

Operating Instructions

2 HP Grinder Pumps

The double seal grinder pumps contain

an electrode for detecting water within

the unit. The electrode is housed within

the seal chamber, isolated from the

motor chamber by a mechanical shaft

seal. If the electrode detects water

within the oil-filled housing, it will close

the circuit to the alarm light in the

control panel, indicating the motor must

be serviced before the upper mechanical

shaft seal fails. The BLUE conductor is

connected to the seal leak probe.

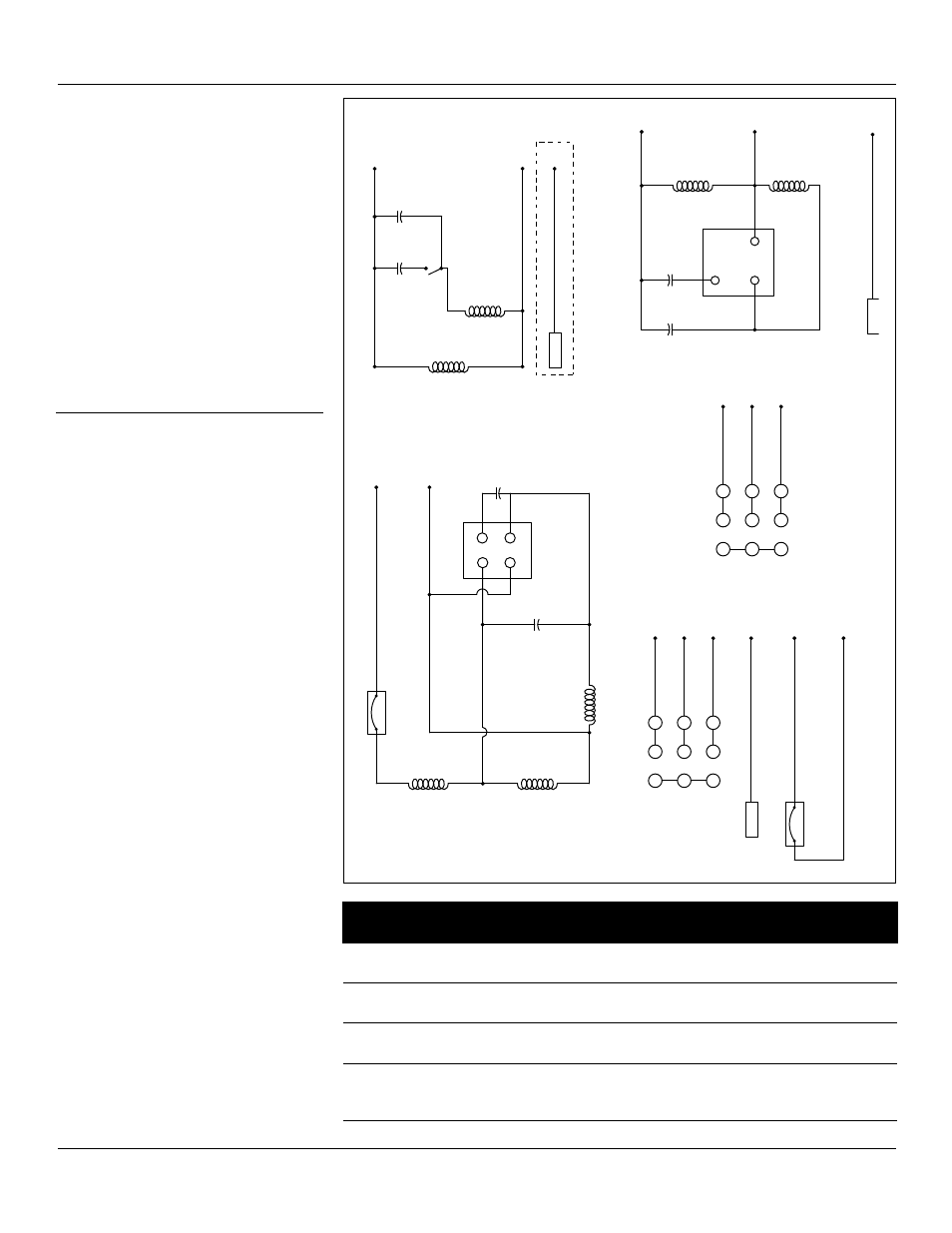

Refer to Wiring Diagrams for model

specific wiring directions (See Figure 2).

control Panel and

level sensing

BAGP1 & BADSGP1 grinder pumps

have internal start and run capacitors.

No control panel is required for

operating the pump. An alarm box is

recommended for high water alarm.

See Chart 2 for starting component

specifications per model.

BARDSGP1 and BAHGP2 models require

control boxes containing properly sized

start and run capacitors. Single-phase

models require a Single-Phase Control

Box with starting components equal to

specifications listed in Chart 2.

The three-phase models require a Three-

Phase Control Box with circuit breaker

and overload heaters per the chart.

Intrinsically safe type float controls are

recommended for all applications. An

intrinsically safe control panel relay will

limit the current and voltage to the level

controls. A control panel can be supplied

with this type of circuitry.

Recommended level sensing settings:

1. The lower “turn-off” control should

be set so the pump stops with the

liquid level at the top of the motor

housing.

2. The upper “turn-on” control should

be set approximately 8” above the

“turn-off” control. This should limit

the number of pump starts to not

exceed 10 starts per hour.

3. The “lag-on” control for duplex

operation should be set 4” above

the “turn-on” control.

4. The “alarm” control is set 10” above

the “turn-on” control.

5. No control should be set above the

inlet pipe.

Start Windings

Main Windings

Run Cap.

Start Cap.

Cent Switch

1.

WHITE

2.

BL

A

CK

3.

RED

BAGP1

BADSGP1

1

2

3

7

8

9

4

5

6

1.

WHITE

2.

BL

A

CK

3.

RED

BL

UE

M

oistur

e S

ensor

Ther

mal S

ensor

WHITE

BR

O

WN

230 Volt 3 Phase

60Hz

BARDSGP1-2023

1.

WHITE

2.

BL

A

CK

Start Windings

Main Windings

5

2

1

3.

RED

Run Cap.

Start Cap.

4.

BL

UE

M

oistur

e S

ensor

BARDSGP1-2021

230 VAC, 1 Phase 60 Hz

Start Relay

Main Windings

Main Windings

Star

t W

indings

4

1

3

2

Start Cap.

Run Cap.

Ther

mal S

ensor

1.

WHITE

2.

BL

A

CK

4.

LEAD

3.

RED

230 Volt 1 Phase

60Hz

BAHGP2-2021

230 Volt 3 Phase

60Hz

4

5

7

1

8

2

1.

WHITE

2.

BL

A

CK

6

9

3

3.

RED

BAHGP2-2023

4.

BL

UE

M

oistur

e S

ensor

BADSGP1

(only)

Figure 2 - Wiring Diagram

www.waynewatersystems.com

Model #

start

capacitor

Run

capacitor

starting

Relay

BAGP1-115

BADSGP1-115

200mF

250 Vac

70mF

250 Vac

NA

BAGP1-2021

BADSGP1-2001

270-300mF

250-370 Vac

30mF

300 Vac

NA

BARDSGP1-2021

270-300mF

250-370 Vac

30mF

300 Vac

GE

3ARR3J3G3

BAHGP2-2021

BAHGP2-2021C

BAHCP2-2021E1

400mF

250 Vac

90mF

250 Vac

Stearns

477104012401

chart 2