Rvl (tube) series, Mechanical installation – Badger Meter Vortex Meters User Manual

Page 24

22

Form No. 09-VRX-UM-00007

RVL (TUBE) SERIES

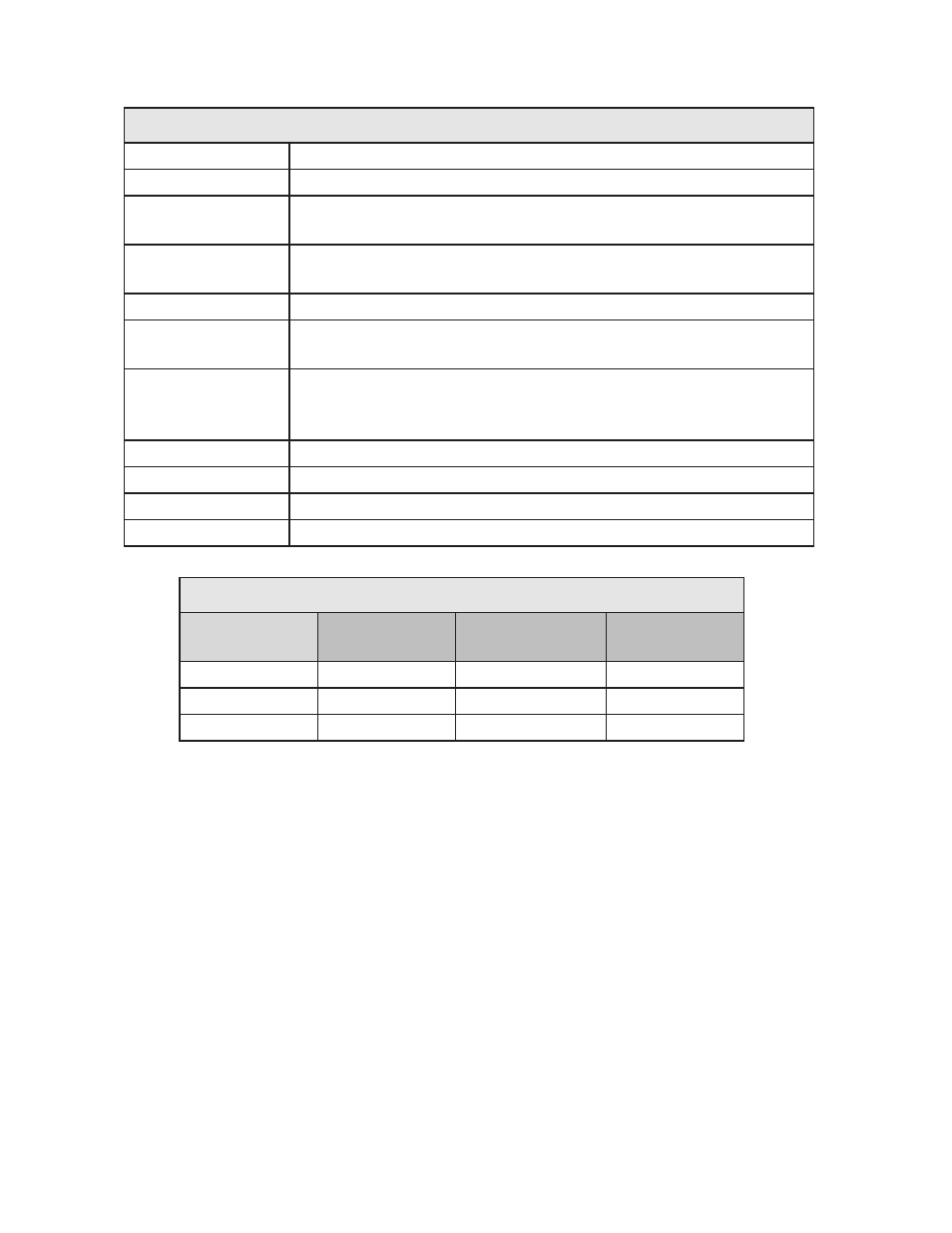

RVL (Tube) Specifications

Fluid:

Liquids

Connection:

Tube (Flare end)

Turndown Ratio:

12:1 (¾”, 1”)

8:1 (½”)

Accuracy:

±1% of full scale (4-20 mA or 0-5 VDC)

±2% of full scale, frequency pulse

Repeatability:

±0.25% of actual flow

Materials

PVC standard

CPVC, Polypropylene, PVDF optional

Output Signals:

4-20 mA standard

0-5 VDC or frequency pulse optional (Push - Pull Driver) 150 mA

Sink or Source

Power Supply:

8 to 28 VDC

CSA Certification:

CSA File 215035, CSA Standard C22.2 No. O-M and No 142-M

Response Time

2 seconds minimum, step change in flow.

Enclosure:

Type 4X (IP 66)

RVL (Tube) Nominal Flow Rates

Tube Size

(inches)

Minimum Flow

gpm (lpm)

Maximum Flow

gpm (lpm)

Weight

lbs (Kg)

½

0.6 (2.3)

5 (18.9)

1.5 (0.68)

¾

1.3 (4.7)

15 (56.8)

1.6 (0.72)

1

2.1 (7.9)

25 (94.6)

1.7 (0.77)

MECHANICAL INSTALLATION

This meter will provide years of accurate service if good flow meter installation practices are followed.

The flow meter should be installed where pipe vibration is minimal.

Observe the upstream piping requirements listed under “Piping requirements”. Upstream valves should

not be used to control flow rate. They should always be kept fully open. Good quality ball valves with

integral unions may be connected directly to the flow meter if the valves are fully open during operation.

This allows easy isolation and removal of the flow meter, should maintenance be required. Cavitation

and flow rate pulsation will adversely affect flow meter performance.

Diaphragm or piston pumps may not be used. Do not use Teflon tape or any kind of pipe dope when pip-

ing.