Water system, Chillers ultima ™ remote air cooled, Installation data – Airedale Ultima Remote Air Cooled 75kW - 450kW User Manual

Page 31

Chillers

ULTIMA

™ REMOTE AIR COOLED

Chillers

31

Technical Manual : Part No 6259485 V1.6.0_07_2014

Installation Data

WATER SYSTEM

Chilled water pipework and ancillary components must be installed in accordance with:

National and Local Water supply company standards.

The manufacturer's instructions are followed when fitting ancillary components.

The system water is treated to prevent corrosion and algae forming.

In ambients of 0°C and below and when water supply temperatures of +5°C are

required, the necessary concentration of Glycol or use of an electrical trace heater

is added where static water can be expected.

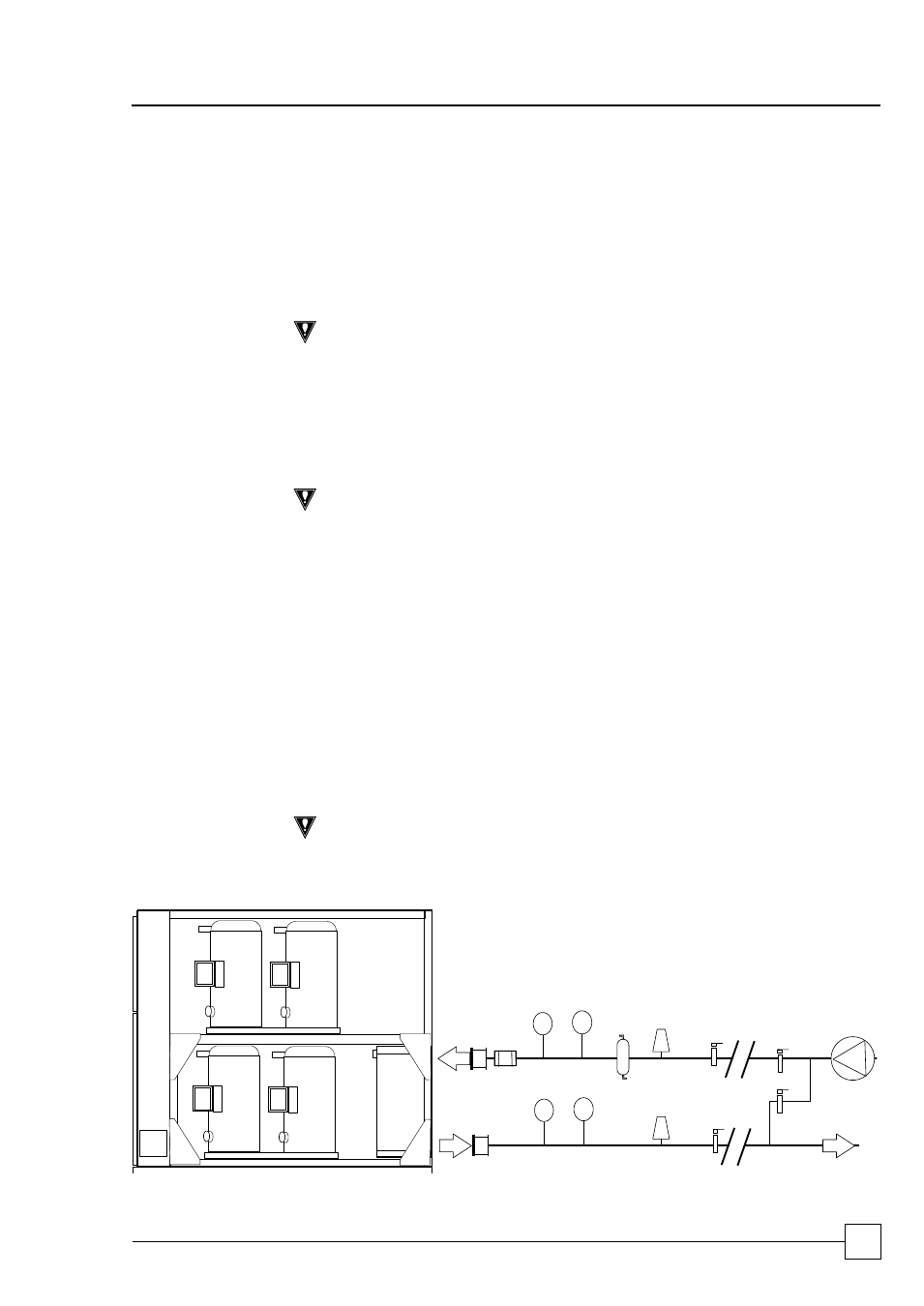

The schematic is referred to as a guide to ancillary recommendations.

CAUTION

The unit water connections are NOT designed to support external pipework,

pipework should be supported during installation.

The water flow commissioning valve set is not shown in the diagram, as the valve can be

fitted elsewhere within the chilled water circuit.

Component

Recommended

Requirements

The recommended requirements to allow commissioning to be carried out correctly are:

The inclusion of Binder Points adjacent to the flow and return connections, to allow

temperature and pressure readings.

A flow switch or equivalent, fitted adjacent to the water outlet side of the Chiller.

CAUTION

The correct operation of the flow switch is critical if the chiller warranty is to

be valid.

A 20 mesh strainer fitted prior to the evaporator inlet.

A water-flow commissioning valve set fitted to the system.

In multiple chiller installations, 1 commissioning valve set is required per chiller

Air vents are to be installed at all high points and where air is likely to be trapped

at intermediate points.

Drain points are to be installed at all low points in the system and in particular

adjacent to the unit for maintenance to be carried out.

Isolating valves should be installed adjacent to all major items of equipment for

ease of maintenance.

Balancing valves can be installed if required to aid correct system balancing.

All chilled water pipework must be insulated and vapour sealed to

avoid condensation.

If several units are installed in parallel adjacent to each other, reverse return

should be applied to avoid unnecessary balancing valves.

Interlocks & Protection

Always electrically interlock the operation of the chiller with the pump controls and water

flow switch for safety reasons. Failure to do this will invalidate the chiller warranty.

CAUTION

Do not rely solely on the BMS to protect the chiller against low flow conditions.

An evaporator pump interlock and flow switch MUST be directly wired to the

chiller, refer to

Standard Recommended Installation (Parts Supplied By Others)

P

T

BYPASS CIRCUIT

(For Flushing)

SHUT OFF

VALVES

TEMPERATURE

GAUGES

PRESSURE

GAUGES

FLEXIBLE

CONNECTIONS

AUTO AIR

VENT (At

Highest Point)

PUMP

PUMP

STRAINER

T

P

OUT

IN

DE-AERATER

(Optional Extra)

FILTER

20 Mesh