Descrizione dei componenti, Circuito frigorifero, Caratteristiche dell'acqua – Airedale EcoChill 6kW - 46kW User Manual

Page 9: Struttura e ventilatori, Circuito idraulico standard, Description of components, Refrigerant circuit, Water characteristics, Structure and fans, Standard hydraulic circuit

9

EcoChill Installation Manual 7481930_v1.6.0_08_2013

ECL-ECLH 020-202

EN

5.

DESCRIPTION OF COMPONENTS

5.1. REFRIGERANT CIRCUIT

SCROLL COMPRESSORS

High efficiency rotary scroll hermetic compressor

(mounted on elastic anti-vibration mounts) with two

pole electric motor. Crankcase heaters as standard,

automatically activated when the unit stops, as long as

power is maintained to the unit.

SYSTEM SIDE HEAT EXCHANGER

Brazed plate heat exchanger in stainless steel AISI 316.

The heat exchanger is externally insulated with closed

cell neoprene anti-condensation material.

DESUPERHEATER

(Only version "D")

Brazed plate heat exchanger in stainless steel AISI 316.

The heat exchanger is externally insulated with closed

cell neoprene anti-condensation material.

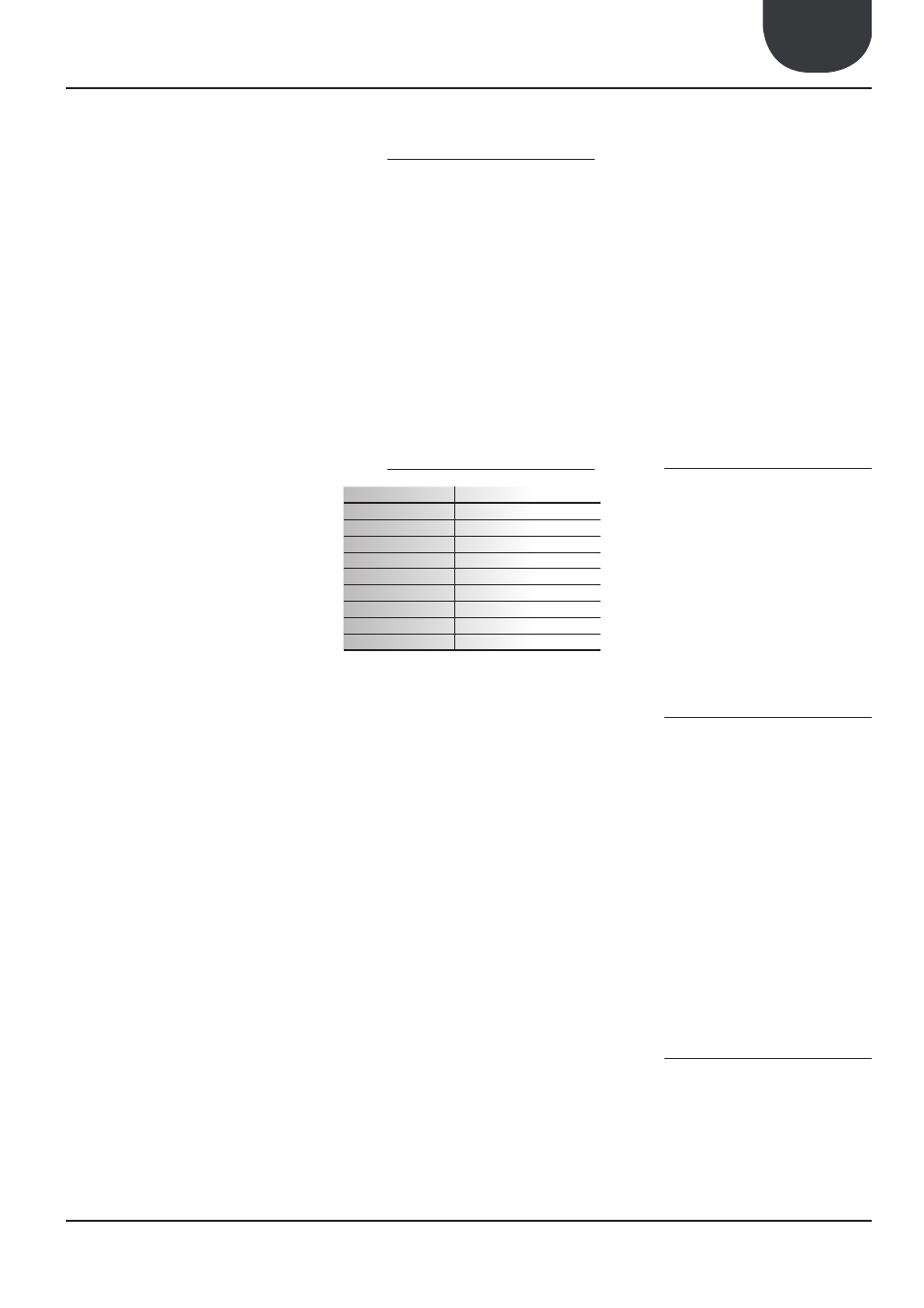

5.2. WATER CHARACTERISTICS

PH

6-8

Electrical conductivity Less than 200 mV/cm (25°C)

Chloride ions

Less than 50 ppm

Sulphuric acid ions

Less than 50 ppm

Total iron

Less than 0.3 ppm

Alkalinity M

Less than 50 ppm

Total hardness

Less than 50 ppm

Sulphur ions

None

Ammonia ions

None

Silicone ions

Less than 30 ppm

SOURCE SIDE MICROCHANNEL HEAT EXCHANGER

(ECL 102 ÷ 202 COOLING ONLY)

All aluminium finned coil heat exchanger of microchan-

nel type. Ensures:

1. Higher energy efficiency that standard coils.

2. Lower refrigerant charge.

SOURCE SIDE STANDARD HEAT EXCHANGER

(ECL 020 ÷ 090 COOLING ONLY)

(ECL 020 ÷ 202 HEAT PUMP)

Finned coil heat exchanger with copper tubes and

aluminium fins adequately spaced to ensure high

efficiencies.

REVERSING VALVE

(only versions "H")

4 way reversing valve. Reverses the flow of refrigerant.

LIQUID ACCUMULATOR

(only versions "H")

Compensates for the difference in volume between the

finned coil and the plpate heat exchanger, retaining the

excessive liquid.

FILTER DRIER

Hermetic type with ceramic cartridge and hygroscopic

material, capable of retaining impurities and moisture

within the refrigerant circuit.

CHECK VALVE

Allows the flow of refrigerant in one direction only.

THERMOSTATIC EXPANSION VALVE

Mechanical type, with external equaliser located at the

evaporator outlet, modulates the flow of refrigerant

into the evaporator based on the load and ensures the

correct superheat of the suction gas.

HOT GAS INJECTION VALVE

(only version "D")

Hot gas injection device upstream of the evaporator.

LIQUID SIGHT GLASS WITH MOISTURE INDICATOR

Used to check for the presence of moisture in the

refrigerant circuit.

LIQUID AND DISCHARGE ISOLATING VALVES

(version "C)

Permit the isolation of refrigerant in case of special

maintenance.

5.3. STRUCTURE AND FANS

STRUCTURE

The main structure is made from hot dip galvanised

steel panels, polyester powder coated and designed

to ensure the maximum access for service and main-

tenance.

The base for sizes 102 - 152 - 202 heat pump units has

holes in the proximity of the coil to permit drainage

of water during the defrost cycle.

FAN ASSEMBLY

External rotor axial fan with helicoidal blades, housed

in a casing, complete with protective grilles. 6 pole

electric motor with thermal protection.

5.4. STANDARD HYDRAULIC CIRCUIT

WATER FILTER

The water filter is provided with a filter mesh with

holes no greater than one millimetre, blocking and

removing from the unit any impurities found in the

hydraulic circuit.

FLOW SWITCH

(on ECL 025…040°A|HA)

The flow switch monitors the flow rate through the

heat exchanger and stops the unit in case of insuf-

ficient flow.

DIFFERENTIAL PRESSURE SWITCH

(on ECL 020…202° -°P N|H - HP N)

(on ECL 050…202°A Q |HA Q)

Located between the inlet and outlet of the evapora-

tor. Monitors the flow rate through the heat exchanger

and stops the unit in case of insufficient flow.

5.4.1. ADDITIONAL COMPONENTS DETAILED IN

THE CONFIGURATOR

PUMPS

Standard or high head

EXPANSION TANK

Membrane type precharged with nitrogen.