Table 1: model number decoder – Advanced Protection XGA User Manual

Page 5

5

raceway connections. Do not use isolating bushings to interrupt

a metallic raceway run.

A separate isolated ground for the SPD is NOT recommended.

Proper equipment connections to grounding system and

ground grid continuity should be verified via inspections and

testing on a regular basis as part of a comprehensive electrical

maintenance program.

On 4-Wire Power Systems, neutral to ground bonding (Main

Bonding Jumper) must be installed per the NEC

®

. Failure to

do so WILL damage SPDs.

UL 1283 required language concerning the installation

of EMI Filters

a) An insulated grounding conductor that is identical in

size and insulation material and thickness to the grounded

and ungrounded circuit supply conductors, except that

it is green with or without one or more yellow stripes,

is to be installed as part of the circuit that supplies the

filter. Reference should be made to Table 250-122 of the

National Electrical Code regarding the appropriate size of

the grounding conductor.

fail SPDs. For this reason, the NEC

®

Article 285 has placed

SPD restrictions on ungrounded systems. As generalizations,

SPDs for ungrounded systems can be installed on grounded

systems with a clamping performance penalty. However, SPDs

for grounded systems installed on ungrounded systems are

almost certainly destined for premature failure. Call APT Tech

Support at (800) 237-4567 for further information.

System Grounding

An equipment grounding conductor must be used on all

electrical circuits connected to the SPD.

For the best performance, use a single point ground system

where the service entrance grounding electrode system is

connected to and bonded to all other available electrodes,

building steel, metal water pipes, driven rods, etc. (for reference

see: IEEE Std 142-2007).

For sensitive electronics and computer systems, we

recommend that the ground impedance measurement be

as low as possible. When metallic raceway is used as an

additional grounding conductor, an insulated grounding

conductor should be run inside the raceway and sized per the

NEC

®

. Adequate electrical continuity must be maintained at all

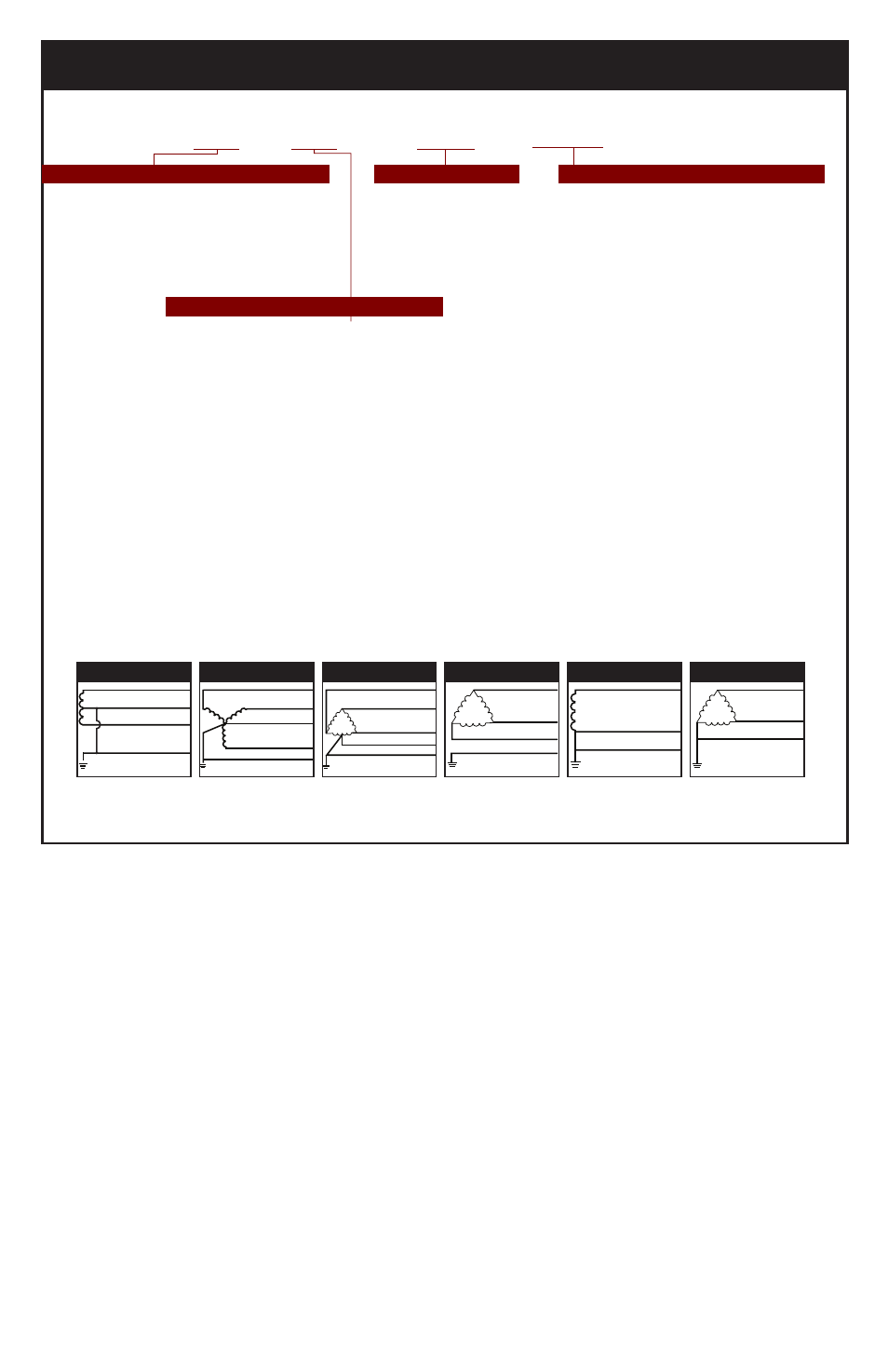

Table 1: MODEL NUMBER DECODER

Do not create model numbers from this chart as all features are not available on all models

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

Figure 6

SPLIT

2 Hots, 1 Neu, 1 Grnd

HI-LEG DELTA (B High)

3 Hots, (B HIGH),

1 Neu, 1 Grnd

SINGLE POLE

1 Hot, 1 Neu, 1 Grnd

WYE

3 Hots, 1 Neu, 1 Grnd

DELTA & HRG WYE

3 Hots, 1 Grnd

CORNER GROUND

DELTA (B grounded)

2 Hots, 1 Grnd

Hot (BLK)

Hot (BLK)

Neutral (WHT)

V

V

}

}

Ground (GRN)

}

Phase A (BLK)

Phase B (BLK)

Neutral (WHT)

Phase C (BLK)

Ground (GRN)

A

C

N

V

B

Phase A (BLK)

Phase B (ORNG)

Neutral (WHT)

Phase C (BLK)

Ground (GRN)

}

V

V

}

Neutral (WHT)

Hot (BLK)

Ground (GRN)

Phase A (BLK)

Phase C (BLK)

Phase B (BLK)

Ground (GRN)

}

V

Phase A (BLK)

Phase C (BLK)

Ground (GRN)

V

}

TE = Transient Eliminator, Listed Type 2

SPD in NEMA 1 enclosure

XTE = Transient Eliminator, Recognized

Type 4 SPD on backplane for installation

within gear in Type 2 installation (display

on 6’ cable)

Common North American Systems:

1 = 240/120V Split Phase - 1Ø 3W+Grnd (Fig 1)

2 = 208Y/120V Wye - 3Ø 4W+Grnd (Fig 2)

3 = 240/120V High Leg Delta (B High) (Fig 3)

4 = 480Y/277V Wye - 3Ø 4W+Grnd (Fig 2)

5 = 480V Delta - 3Ø 3W+Grnd (Fig 4) & HRG Wye

8 = 600Y/347V Wye - 3Ø 4W+Grnd (Fig 2)

Other Available Systems - Confirmation encouraged:

15 = 254/127V Split Phase - 1Ø 3W+Grnd (Fig 1)

18 = 480/240V Split Phase, or Two legs of Wye (Call)

21 = 220Y/127V Wye - 3Ø 4W+Grnd (Fig 2)

41 = 520Y/300V Wye - 3Ø 4W+Grnd (Fig 2)

42 = 415Y/240V Wye - 3Ø 4W+Grnd (Fig 2)

43 = 400Y/230V Wye - 3Ø 4W+Grnd (Fig 2)

44 = 440Y/250V Wye - 3Ø 4W+Grnd (Fig 2)

51 = 480V B Corner Grnd Delta, 3Ø 3W+Grnd (Fig 6)

06 = 240V Delta - 3Ø 3W+Grnd (Fig 4)

61 = 240V B Corner Grnd Delta, 3Ø 3W+Grnd (Fig 6)

07 = 380Y/220V Wye - 3Ø 4W+Grnd (Fig 2)

09 = 600V Delta - 3Ø 3W+Grnd (Fig 4) & HRG Wye

91 = 600V B Corner Grnd Delta, 3Ø 3W+Grnd (Fig 6)

/240

/090

/130

/170

/DC

/SC

/2S

/12

/3R

/04

/FM

/4X

/4S

/TN

RM

Available Accessory (order seperately)

(Note: Enclosure-less version for OEM uses XTE prefix)

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

240kA Option

090kA SAD option

(120/240V & 208Y/120)

130kA SAD option

(120/240V & 208Y/120)

170kA SAD option

(120/240V & 208Y/120)

Dry Contacts

Two sets Form C (24V, 1A)

Surge Counter, six digit LCD

Dual Surge Counter

NEMA 12 Enclosure (12” x 12” x 6”)

NEMA 3R Enclosure

(12” x 12” x 6” - display inside door)

NEMA 4 Enclosure

(12” x 12” x 6” - display inside door)

Flush Mount enclosure, NEMA 1 only

(wall cavity size: 12”x12”x6” deep)

NEMA 4X Non-metallic enclosure

(polycabonate, 14”x12”x6” - display inside door)

NEMA 4S Stainless Steel enclosure

(12”x12”x6” - display inside door)

NEMA 1/12/3R/4 Enclosure

(10” x 10” x 6”)

Remote Monitor

XGA = XGA Family

160kA rating standard

Model Family

Voltage Code for Electrical System

Option Suffixes (Seperated by slashes / )

ll

/

ll

/

XGA /

lll

/

lll

...