Advanced Protection XGA User Manual

Page 2

2

INTRODUCTION

Thank you for choosing an APT Surge Protective Device

(SPD). This is a high quality, high energy surge suppressor

designed to protect sensitive equipment from damaging

transient overvoltages.

Proper installation is important to maximize performance.

Please follow steps outlined herein.

This entire Operation & Maintenance Manual should be

read prior to beginning installation. These instructions are

not intended to replace national or local codes. Follow

all applicable electrical codes to ensure compliance.

Installation of this SPD should only be performed by

qualified electrical personnel.

APT SPDs are extensively tested in accordance with industry

standards such as ANSI/IEEE C62.41.1, C62.41.2, C62.45,

C62.62, C62.72, UL 1449, UL 1283, IEC 61643, etc.

This SPD is a single-port parallel-connected device

intended for service entrance, panelboard or downstream

installation for IEEE Category C, B or A applications.

Major Industry Nomenclature Changes

Effective 2008-2009

Be aware that UL 1449 Third Edition and 2008 NEC

®

Article

285 generated substantial changes.

▪

The term TVSS changed to SPD

▪

Types 1, 2, 3 & 4 SPDs are created

▪

UL 1449 clamping voltage performance testing

changed from 500A to 3,000A

▪

UL 1449 added new I nominal testing (I

n

), which

consists of more rigorous duty-cycle testing

This SPD complies with the latest regulatory actions and

is UL Listed as such.

For further information, please review latest editions of

NEC

®

Art. 285, UL 1449 or contact APT Tech Support at

(800) 237-4567.

GENERAL INFORMATION

This is a Type 2 SPD. It includes internal overcurrent protection.

Type 2 SPDs are suitable for installation on the load side of the

service disconnect overcurrent device.

This device features internal overcurrent and overtemperature

protection that will disconnect effected surge suppression

components at the end of their useful life, but will maintain

power to the load – now unprotected. If this situation is

undesirable for the application, follow these instructions for

servicing or replacing the device.

Service of this unit consists of replacing internal modules and/

or display assembly.

There are no user-serviceable parts inside the replaceable

modules. Do not attempt to disassemble the module as it stores

charge and is potted.

Simplified Explanation of Operation

SPDs sense overvoltage and create a momentary short

circuit to redirect harmful surge energy to earth ground.

Then they reset automatically and wait for the next surge.

This is similar to the pressure relief valve on a water

heater: pressure goes up, valve opens to relieve pressure

and then resets. In an electrical system, an SPD senses

overvoltage, shorts temporarily sending energy to ground

and then resets. SPDs are capable of repeating this

function thousands of times.

Parallel Connection

This is a Parallel connected SPD – not series connected.

As outlined above, an SPD ‘drains off’ excessive voltage

from an electrical system. Because of parallel connection,

installation of the SPD near the equipment to be protected

is satisfactory. This effect is similar to flushing any toilet in a

house; pressure in the shower goes down. In an electrical

system, a parallel connected SPD will remove excessive

voltage off the entire system (assuming reasonable

proximity).

Tip: It is critically important that wiring leads be configured as

short & straight as possible. Avoid long leads. Avoid sharp

bends. Route SPD conductors in the same conduit. Leads do

not have to be sized for the entire load – this SPD is parallel

connected, not series connected. As a generalization, 6 AWG

works fine.

Precautionary Statement Regarding SPDs on

Ungrounded Systems

Caution – Ungrounded systems are inherently unstable and

can produce excessively high line-to-ground voltages during

certain fault conditions. During these fault conditions, any

electrical equipment including an SPD, may be subjected

to voltages which exceed their designed ratings. This

information is being provided to the user so that an informed

decision can be made before installing any electrical

equipment on an ungrounded power system.

Unpacking & Preliminary Inspection

Inspect the entire shipping container for damage or signs

of mishandling. Remove the packing materials and further

inspect the unit for any obvious shipping damages.

If any damage was found and is a result of shipping or

handling, immediately file a claim with the shipping company

and forward a copy to APT.

Storage Environment

This SPD should be stored in a clean, dry environment.

Storage temperature range is -40°C (-40°F) to +60°C

(+140°F). Avoid exposure to high condensation.

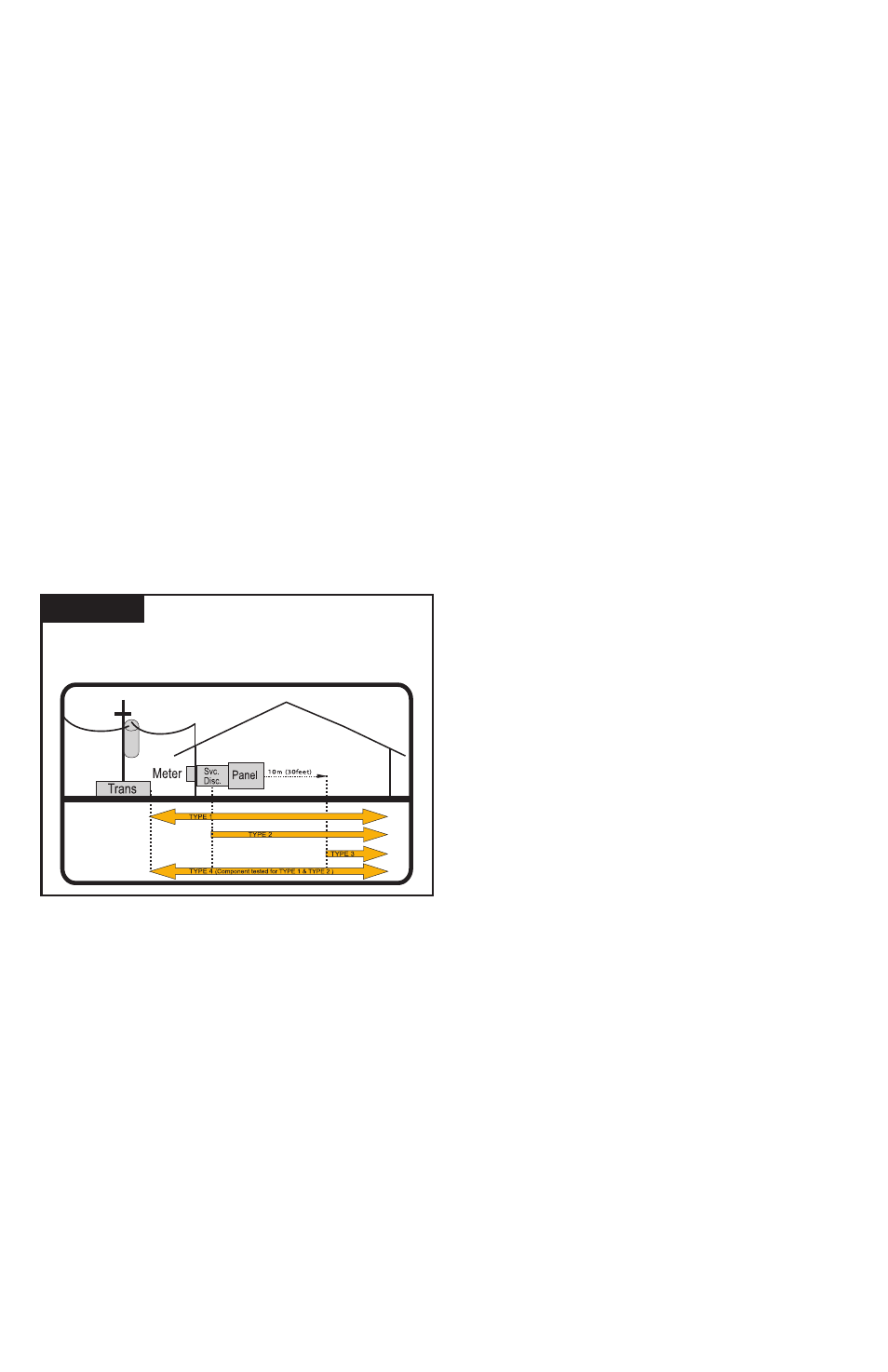

SPD Types: Types 1, 2, 3, & 4

Based on Location within electrical distribution system

(also coincides with ANSI/IEEE C62.41.2 - 2002 Categories C, B & A)

Figure 1

NEC

®

Article 285 & UL 1449-3