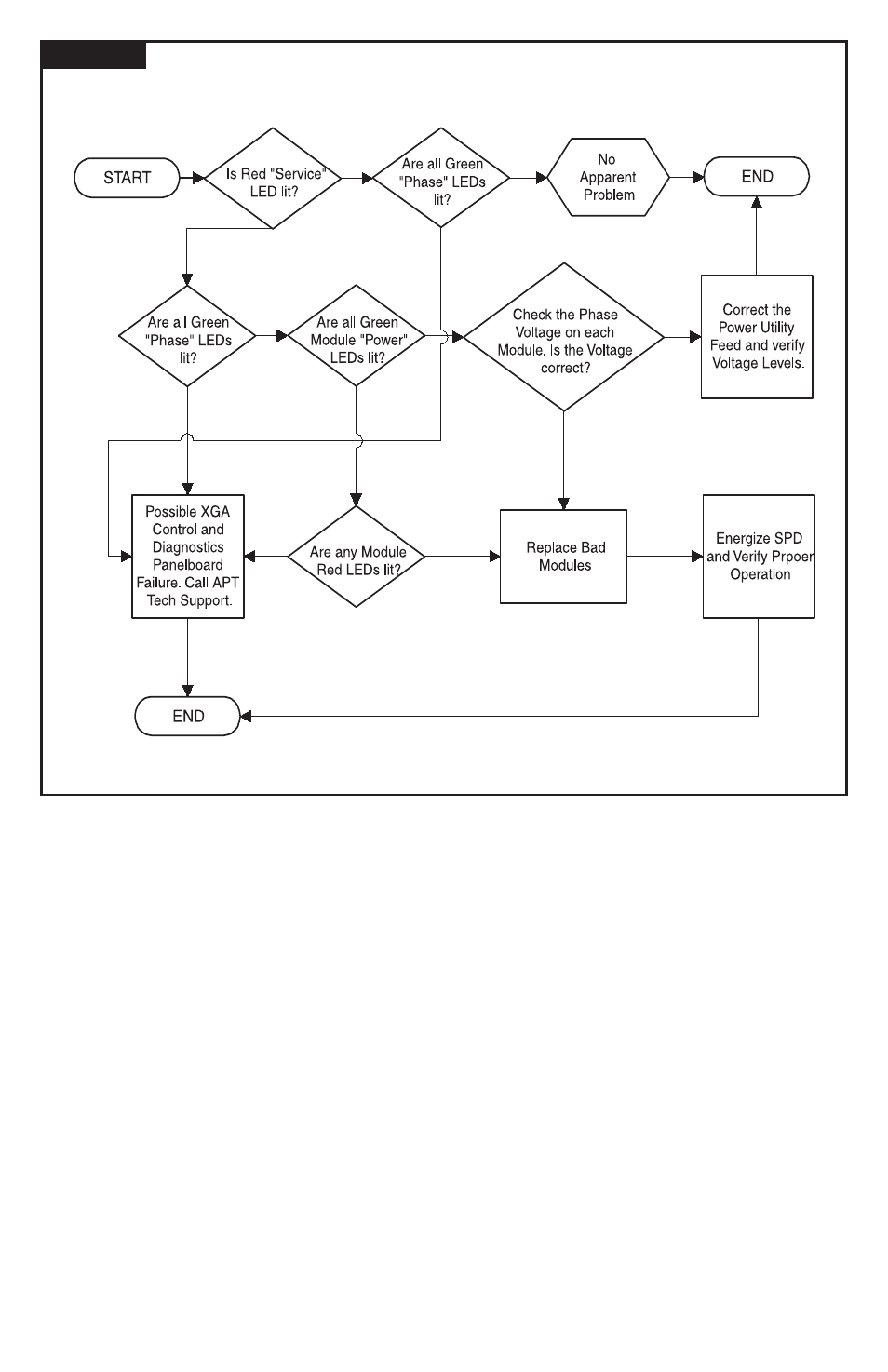

Figure 17 troubleshooting flowchart – Advanced Protection XGA User Manual

Page 11

11

Figure 17

TROUBLESHOOTING FLOWCHART

No

Yes

No

No

Yes

No

Yes

Yes

No

No

No

Yes

Yes

Module Removal and Replacement

Disconnect power to the SPD. DISCHARGE INTERNAL

CAPACITORS BY GROUNDING. Unplug the 10 pin

connector from the XGA module. Using a 7/16” socket

wrench, remove the bolts on both ends of the module, and

pull the module out. Make note of the location and part

number of each module removed, as this part number is not

referenced anywhere else on the SPD. The module(s) should

only be replaced with a new module bearing the same part

number as the module(s) previously removed. Replace with

a new module by reversing the procedure. Torque bolts to 65

inch-pounds, power up the SPD and verify the green module

LED is lit and all alarms have been cleared.

Display/Diagnostic Board Removal and Replacement

Disconnect power to the SPD. Remove the nuts from

the switches that secure the board to the panel, then

remove the board. Remove the connectors one at a

time from the existing board and insert them into the

appropriate connector on the replacement board. Install

the replacement board into the panel and install the nuts

onto the switches and tighten securely.

Note that a sealing gasket between the display and the

enclosure is a key component ensuring weather resistance.

Replace the gasket whenever the display is removed.

Preventive Maintenance (Inspection and Cleaning)

Inspection of the SPD should be performed periodically

to maintain reliable system performance and continued

transient voltage surge protection. While it is difficult to

establish a preventive maintenance schedule because

conditions vary from location to location, inspections for

inoperative modules and other signs of trouble utilizing

the built-in diagnostics should be performed on a routine

basis (weekly or monthly).

Corrective Maintenance (Repair)

APT’s Surge Protective Devices are designed for years

of reliable, trouble-free operation. Unfortunately, even

the most reliable equipment can become inoperative.

On-line diagnostics are an integral part of the SPD and

will aid in isolating which of the protection module(s) have

become inoperative. To keep the SPD operating at peak

performance, replacement of any inoperative module(s)

should be performed according to module removal and

replacement instructions at the earliest service opportunity.

Troubleshooting procedures should be used to isolate

other problems not associated with inoperative module(s).

See Figure 17, Troubleshooting Flow Chart on page 10 for

assistance. Be sure to replace components with identically

rated parts to continue proper operation and safety. Table

3 lists typical replacement parts.