Advanced Protection XGA User Manual

Page 4

4

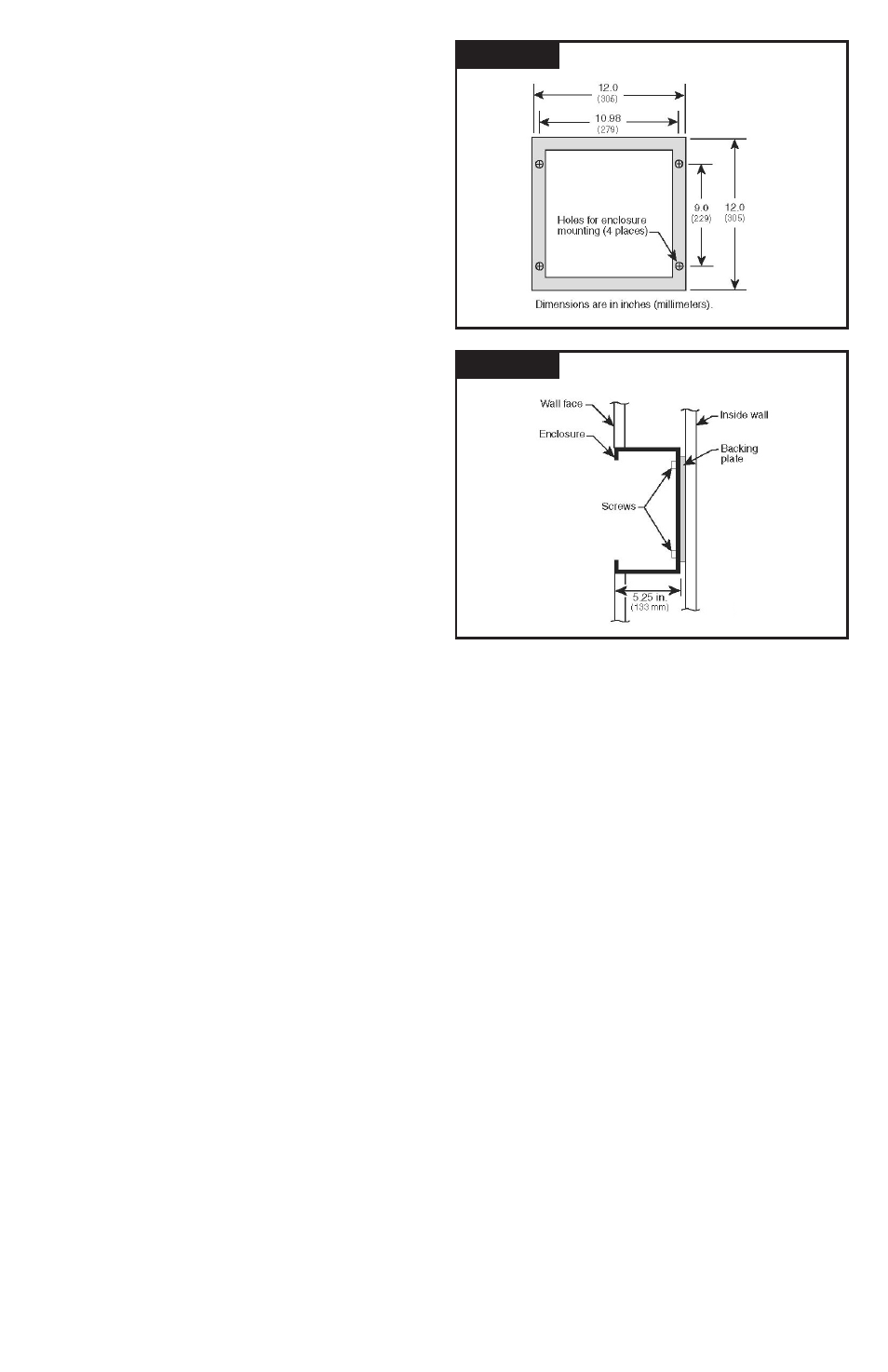

The XGA is approximately 5.25 in. (133 mm) deep. The XGA

will not flush mount unless there is at least 5.25 in. (133 mm)

of clearance. The XGA is not designed to flush mount on a

typical 2 x 4 stud wall.

Follow steps 1-5 to flush mount the XGA.

1. Before removing the trim, disconnect the ribbon cables

and ground wire from the modules.

2. Mount the device as close as possible to the panel being

protected. Create a wall opening slightly larger than 12

in. high by 12 in. wide (305 mm high by 305 mm wide).

See figure 2.

3. Install a backing plate inside the wall cavity 5.25 in.

(133 mm) from the wall face such that the XGA will be

supported from its back. See figure 3. Note the mounting

holes on the back of the enclosure. Also note that the

XGA weighs 25 lb (12 kg) maximum.

4. Configure the electrical conductor and conduit

connections consistent with the wiring instructions

beginning on page 7.

5. Carefully reattach the ribbon cables and the ground wire

to the modules and reattach the display panel/cover

before energizing and testing the device.

Terminals

Terminals will accept 14 - 2 AWG conductor and are provided

for line (phase), neutral (if used), and equipment safety

ground connections. 8 AWG is the minimum recommended

wire size because UL testing and evaluation was performed

using 8 AWG.ators to ensure proper operation. We also

recommend keeping the SPD clean as appropriate.

Shortest Leads Possible

• Leads must be as short and straight as possible-

See NEC

®

Art. 285.12

• Pretend wire is $1000 per foot coming out of your pocket

• No long leads

• No sharp bends

• No wire nuts

• How short is short enough? As short as you can make it

• How long is too long? If anyone else can make it shorter

Configuration Management & Part Numbering System

TE series correct installation orientation is such that the door

will hinge from the left. (XTE has no enclosure or door and is

typically factory installed)

Locate the unit’s printed identification nameplate on the inside

of the hinged door, although options may dictate placing it in

a conspicuous location elsewhere. The model number can

be decoded as follows:

• TE identifies an external mount Transient Eliminator

®

followed by a slash (/). XTE identifies an enclosure - less

model followed by a slash (/).

• A one or two digit number will precede the letters XGA.

This number indicates the voltage and wiring configuration

of the device. Refer to page 5 to identify and confirm

correct application.

• XGA identifies the XGA Series, followed by a slash (/)

• Following the second slash may be a /240. These numbers

identify optional per phase Surge Current Ratings. (Please note:

The Standard 160kA Rating does not have a /160 identifier.)

Options are identified after the Surge Current Rating and

are individually separated by a slash. (Options are detailed

later in this manual.)

Example: TE/2XGA/240/DC/RM/4X identifies a Transient

Eliminator

®

XGA Series SPD (external mount), 208Y/120V, 3

Phase, 4 Wire (plus Ground), with a 240kA per phase Surge

Current Rating with: Dry Contact, Remote Monitor and a

NEMA 4X Enclosure.

Voltage Rating

Before installing SPD, verify that it has the same voltage

rating as the power distribution system. Compare the SPD’s

nameplate voltage or model number and ensure that SPD

configuration matches the intended power source. See Table 1.

The specifier or the user of the device should be familiar with the

configuration and arrangement of the power distribution system

in which any SPD is to be installed. The system configuration

of any power distribution system is based strictly on how the

secondary windings of the transformer supplying the service

entrance main or load are configured. This includes whether

or not the transformer windings are referenced to earth via a

grounding conductor. The system configuration is not based on

how any specific load or equipment is connected to a particular

power distribution system.

480V System Example: SPDs should be installed per the

electrical system, not per a load or motor’s wiring connection.

For example, a 480V three phase motor might appear to be

connected as a 480V Delta. In actuality, the serving distribution

system might be a 480Y/277V grounded Wye, with or without

a neutral pulled to the motor or MCC. The system is still a

480Y/277V Wye, even though the load is connected as a

Delta. A grounded Wye has a defined reference to ground

(i.e., neutral is bonded to ground). Some Delta systems are

ungrounded, which have no reference to ground and are known

to become unstable in certain situations. Such instability can

cause line to ground voltage fluctuations that may prematurely

Figure 2

FLUSH MOUNT FRONT VIEW

Figure 3

FLUSH MOUNT SIDE VIEW