Corr, Fnc.1, Fnc.2 (fnc.3) – West Control Solutions TB 45 Temperature Limiter User Manual

Page 34: Src.2 (src.3)

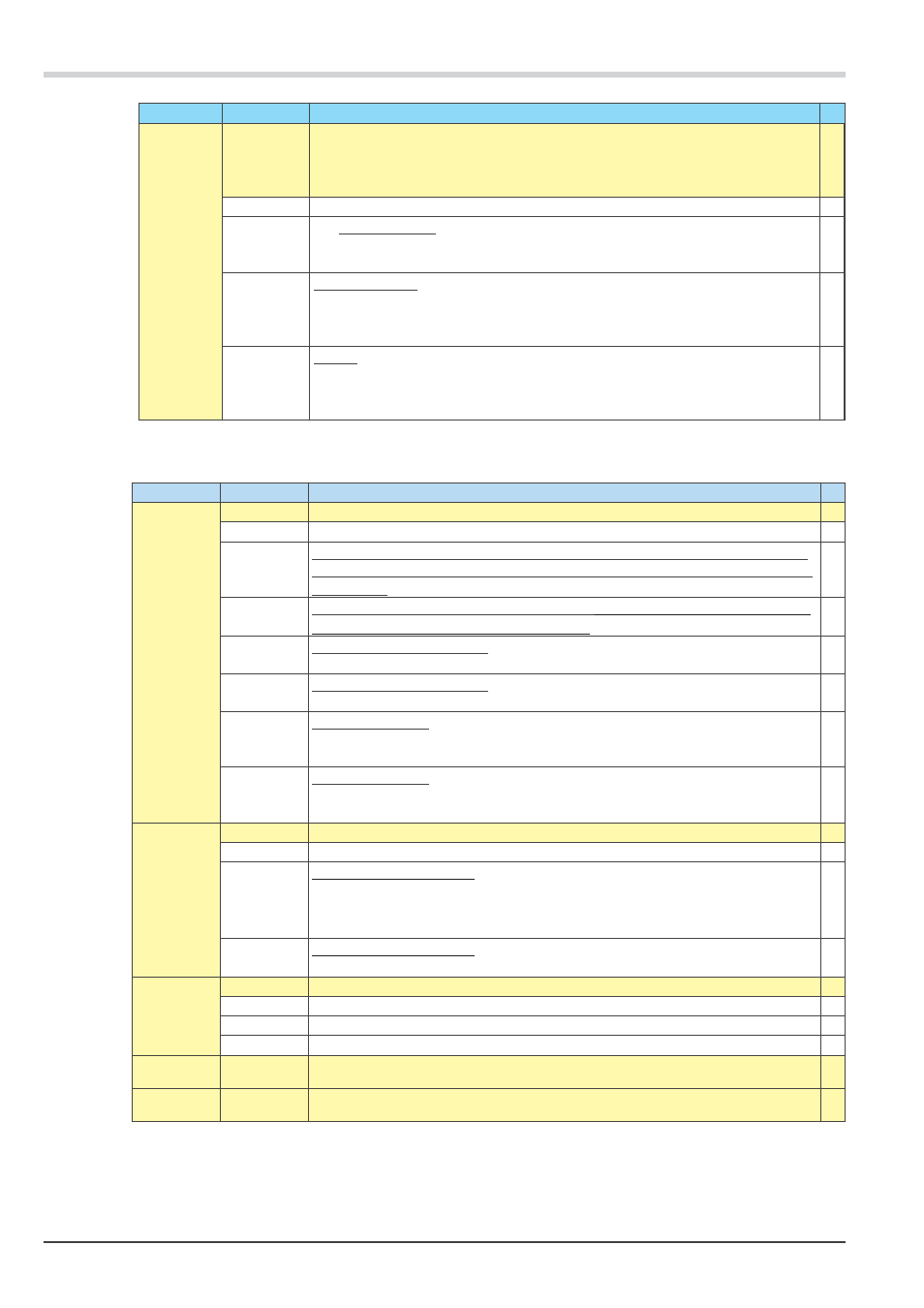

Name

Value range Description

Corr

Measured value correction / scaling:

When using current, voltage orr (version-dependent) resistance signals as input va-

riables, scaling at parameter level is possible. Specify the input value of the lower

and upper scaling point in units of the relevant electrical quantity (mA / V/ Ohm).

0

No correction

1

The offset correction (at CAL level) is possible on-line at the process. If InL shows the

lower input value of the scaling point, OuL must be set to the relevant display value.

Adjustment is via the instrument front panel.

2

2-point correction (at CAL level) is possible off-line by means of a process value

transmitter. Specify the process value for the lower and the upper scaling point and

confirm it as input value InL or InH. Now, adjust the relevant display value OuL or

OuH. Adjustment is via instrument front panel operation.

3

Scaling (at PArA level) for current and voltage signals as input variables also for re-

sistance signals dependent on version). The input and display value values for lower

(InL, OuL) and upper scaling point (InH, OuH) are visible at parameter setting level.

Adjustment is via instrument front panel operation, or via the engineering tool.

Limit values LC, Lim2, Lim3

Name

Value range Description

Fnc.1

Function of main alarm LC

0

switched off

1

Measured value monitoring. When exceeding the limit value, an alarm is output and

reset automatically, when the measured value is "within the limits" (including hyste-

resis) again.

2

Measured value monitoring + alarm status latch

. A stored limit value can be reset by

pressing the RESET key or via the digital input (

→ LOGI/ Err.r).

5

Temperature monitor function for exceeded high limit value. As opposed to the tem-

perature limiter function, the limit value is not stored.

6

Temperature monitor function for exceeded low limit value. As opposed to the tempe-

rature limiter function, the limit value is not stored.

7

Temperature limiter fo

r high limit value: measured value monitoring + high limit value

alarm status latch. A stored limit value can be reset via a digital input or by pressing

the RESET key (-> LOGI/Err.r).

8

Temperature limiter fo

r low limit value: measured value monitoring + low limit value

alarm status latch. A stored limit value can be reset via a digital input or by pressing

the RESET key (-> LOGI/Err.r).

Fnc.2

(Fnc.3)

Function of pre-alarm 2 / 3

0

switched off

1

Measured value monitoring

If a limit is exeeded an alarmsignal is executed. It becomes resetted automatically,

when the measured value has returned to the "acceptable" range (including hystere-

sis).

2

Measured value monitoring + alarm status latch. A stored limit value can be reset via

error list or a digital input (

→ LOGI/ Err.r).

Src.2

(Src.3)

Source for pre-alarms 2 /3

0

Process value = absolute alarm

1

Process value - limit value LC = relative alarm

3

Measured value of the analog input INP1

C.Std

OFF; 1 …

9999999

Monitoring operating hour (only visible with BlueControl!)

C.Sch

OFF; 1 …

9999999

Monitoring duty cycle (only visible with BlueControl!)

Configuration level

34

Configuration

TB 45