Commands/r, Specifications, Calibration – SHIMPO FGV-series User Manual

Page 4: Response from fgv gauge, Commands to fgv gauge, Required for calibration, Calibration procedure, Error symbols, Shimpo instruments

4

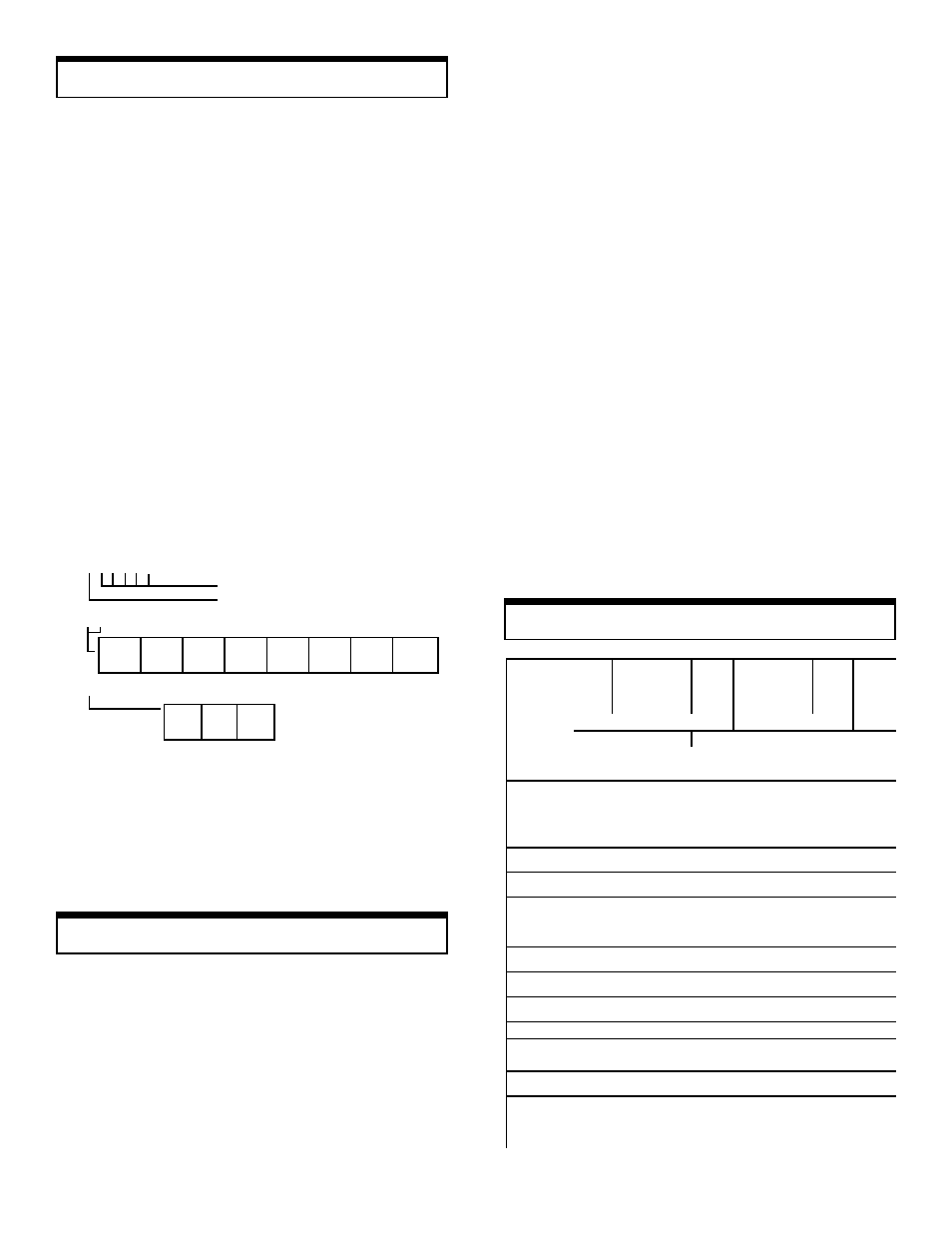

Response from FGV Gauge

NA!!!!!! cr:

Average data output

NB!!!!!!cr:

Peak data output

4-digit number with decimal point

sign (+ or –)

Commands/R

Commands/R

Commands/R

Commands/R

Commands/Responses

esponses

esponses

esponses

esponses

The FGV series of force gauges has the ability to recognize

and respond to various commands from outside peripherals. If

for instance the gauge receives a legitimate command from a

PC, it will respond by sending back the same code indicating

to the PC that the command was recognized. If for example the

command is a request for average data output, it will send the

data and the code NA etc. If the gauge recognizes an error

while it is receiving a command, an error symbol is transmitted

back to the PC indicating the exact nature of the error.

Commands to FGV Gauge

AAcr:

Tare

ABcr:

Stop output

ACcr:

Change to peak mode

ADcr:

Change to average mode

AEcr:

Peak reset

AFcr:

Change units to kg (g)

AGcr:

Change units to N

AHcr:

Change units to lb (oz)

BAcr:

Data output request

BBcr:

Continuous data output request (10 times/sec)

BCcr:

Model name confirmation request

BDcr:

Units confirmation request

BEcr:

Peak data output request

SHIMPO INSTRUMENTS

1701 Glenlake Avenue, Itasca, IL 60143 USA

"

#

(630) 924-7138 FAX (630) 924-0342

Specifications

Specifications

Specifications

Specifications

Specifications

MODELS

MODELS

MODELS

MODELS FGV-0.5

FGV-0.5

FGV-0.5

FGV-0.5

FGV-1

FGV-1

FGV-1

FGV-1

FGV-2

FGV-2

FGV-2

FGV-2

FGV-5

FGV-5

FGV-5

FGV-5

FGV-10

FGV-10

FGV-10

FGV-10

FGV-20

FGV-20

FGV-20

FGV-20

FGV-50

FGV-50

FGV-50

FGV-50

FGV-100

FGV-100

FGV-100

FGV-100

CAPACITY

CAPACITY

CAPACITY

CAPACITY

8 oz

200 g

2 N

16 oz

500 g

5 N

2 lb

1000 g

10 N

5 lb

2 Kg

20 N

10 lb

5 Kg

50 N

20 lb

10 Kg

100 N

50 lb

20 Kg

200 N

100 lb

50 Kg

500 N

RESOLUTION

RESOLUTION

RESOLUTION

RESOLUTION

0.01 oz

0.001 lb

0.01 lb

0.1 lb

0.1 g

1 g

0.001 Kg

0.01 Kg

0.001 N

0.01 N

0.1 N

ACCURACY

ACCURACY

ACCURACY

ACCURACY ±0.2% FS plus 1/2 digit at 73°F (23°C)

DISPLAY

DISPLAY

DISPLAY

DISPLAY 4-Digit LCD 12mm high. Reversible by a push of a button. Minus sign for tension.

AVERAGE/

AVERAGE/

AVERAGE/

AVERAGE/

PEAK MODE

PEAK MODE

PEAK MODE

PEAK MODE Yes (selectable)

LOW BATTERY

LOW BATTERY

LOW BATTERY

LOW BATTERY

INDICATION

INDICATION

INDICATION

INDICATION Yes

DISPLAY

DISPLAY

DISPLAY

DISPLAY

UPDATE

UPDATE

UPDATE

UPDATE 0.3 second

SAMPLING

SAMPLING

SAMPLING

SAMPLING

RATE

RATE

RATE

RATE 35 times per second

OVERLOAD

OVERLOAD

OVERLOAD

OVERLOAD 200% of FS

POWER

POWER

POWER

POWER Rechargeable Ni-Cad batteries or AC through adapter/charger

OUTPUT

OUTPUT

OUTPUT

OUTPUT RS232C and ±1VDC (through a 12 bit D/A converter)

AUTO POWER

AUTO POWER

AUTO POWER

AUTO POWER

OFF

OFF

OFF

OFF Yes (not active if adapter/charger is in use)

BATTERY

BATTERY

BATTERY

BATTERY

CHARGE

CHARGE

CHARGE

CHARGE 20 hrs. when fully charged

RECHARGE

RECHARGE

RECHARGE

RECHARGE

TIME

TIME

TIME

TIME

12 hrs. approx.

TEMPERATURE

TEMPERATURE

TEMPERATURE

TEMPERATURE 32° - 104°F (0° - 40°C)

DIMENSIONS

DIMENSIONS

DIMENSIONS

DIMENSIONS 5.1"L x 2.9"W x 1.5"H (130 x 75 x 38)mm

WEIGHT

WEIGHT

WEIGHT

WEIGHT 1lb (450g)

OVERLOAD

OVERLOAD

OVERLOAD

OVERLOAD

OUTPUT

OUTPUT

OUTPUT

OUTPUT

One NPN OC transistor for tension, one NPN OC transistor for compression

ACCESSORIES

ACCESSORIES

ACCESSORIES

ACCESSORIES

(INCLUDED)

(INCLUDED)

(INCLUDED)

(INCLUDED)

AC adapter/charger, carrying case, hook ,chisel, flat head, notched head, hanger,

cone head, extension rod and analog output cable.

ACCESSORIES

ACCESSORIES

ACCESSORIES

ACCESSORIES

AVAILABLE

AVAILABLE

AVAILABLE

AVAILABLE Test stands, RS232C cable, overload cable.

Calibration

Calibration

Calibration

Calibration

Calibration

Required for Calibration:

1. A secure calibration stand to mount a force gauge upside-

down.

2. The appropriate calibration weight for your force gauge:

Calibration Procedure:

1. Turn POWER off.

2. Mount the force gauge upside-down on the calibration stand.

3. Attach the hook on the sensing shaft of the force gauge.

4. Press and hold the UNIT, PEAK and ZERO switches.

5. Press and release the POWER switch (while continuing to

press UNIT, PEAK and ZERO) until the smaller characters

at the top area of the display show

CAL. Release the UNIT,

PEAK and ZERO switches. The force gauge is now in cali-

bration mode.

6. Press the UNIT switch. The display will show

ZER. The

force gauge is now ready for zero point calibration.

7. Press ZERO to zero point calibrate. Wait 5 seconds. The

display will change to show

PEK. Do not press any other

switches or move the sensing shaft during calibration.

8. Hang the calibration weight on the hook and stabilize; the

larger characters on the display will change. The force gauge

is now ready for full scale calibration.

9. Press the PEAK switch to begin full scale calibration. Do not

press any other keys or touch the weight during calibration.

After approximately 5 seconds the display will show

END.

10. Press the UNIT switch. If calibration was successful, the

display will show

OK momentarily, then automatically power

off. If calibration was unsuccessful, the display will show

ERR. Remove the calibration weight and repeat the proce-

dure from step 6.

MODEL WEIGHT

FGV-0.5 200g

FGV-1 500g

FGV-2 1Kg

FGV-5 2Kg

MODEL WEIGHT

FGV-10 5Kg

FGV-20 10Kg

FGV-50 20Kg

FGV-100 50Kg

02

03

04

05

06

07

08

09

FGV-0.5

FGV-1

FGV-2

FGV-5

FGV-10 FGV-20 FGV-50 FGV-100

0

1

2

N

Kg (g) lb (oz)

Error symbols:

OBcr:

Command error

ODcr:

Overload error

OEcr:

Parity error

OFcr:

Format error

OGcr:

Summing error

OHcr:

Overrun error

NH!cr:

Unit

NE!!cr:

Model number