KROHNE DW 181-182-183-184 EN User Manual

Page 9

Installation and operating instructions DW 181 - 184

9

1 Mechanical

Installation

1.1

Positioning the flow switch

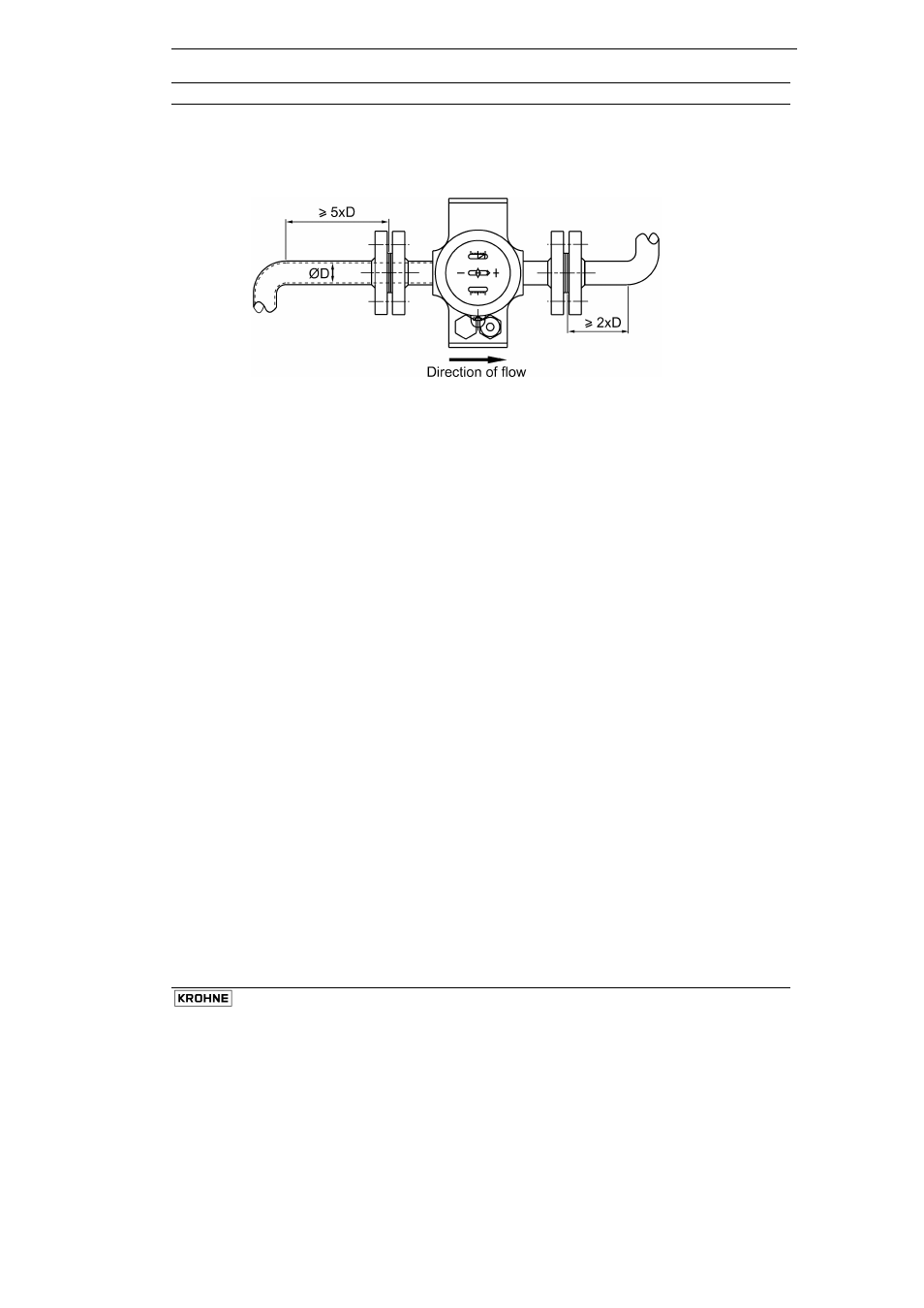

No obstacles along the pipe within five diameters (D) upstream and two diameters downstream of

the instrument.

1.2

Installation in hazardous areas (Ex applications)

Read all instructions referring to flow switches in hazardous locations before installation.

Check that the flange, gasket and other materials in contact with the product are compatible. Refer

to the information given on the converter nameplate, the flange markings and specifications given

in the ATEX approval certificate.

1.3

Connecting the DW 18 to the pipe

• Before installation, clean the piping to remove any dust or weld debris.

• Fit the instrument on the pipe with the arrow on the housing pointing in the direction of flow.

• Flange connections: ensure that the gaskets are in place, flange facings are aligned and parallel

and that the bolts have been tightened with the amount of torque specified in European or local (if

outside the E.U.) standards.

1.4 Flow

direction

The DW 183 and DW 184 can be installed in any position on the piping. However, the position of

installation and the flow direction must be indicated in the customer order (i.e. up, down, left to right

and right to left) as the weight of the baffle disc is taken into account when calibrating the

instrument. Flow direction must be indicated for DW 181 and DW 182 instruments equipped with

type A indicators.

The DW 184 is used for high-velocity or turbulent flows in pipes with diameters greater than

DN250. A special device, called a stilling well, is immersed in the liquid flow and channels the fluid

through a tube in which the disc moves, secured to the end of a rigid support. This reinforced pivot

enables the flow switch to be used in difficult conditions.

These instruments are only supplied with an index display (indicator type “G”) and switches. They

are not equipped with a graduated dial. The heights of the connection piece indicated for the

production of the mating flange must be respected.