KROHNE DW 181-182-183-184 EN User Manual

Page 36

36

Installation and operating instructions DW 181 - 184

8 Measuring

Principle

8.1 Measuring

systems

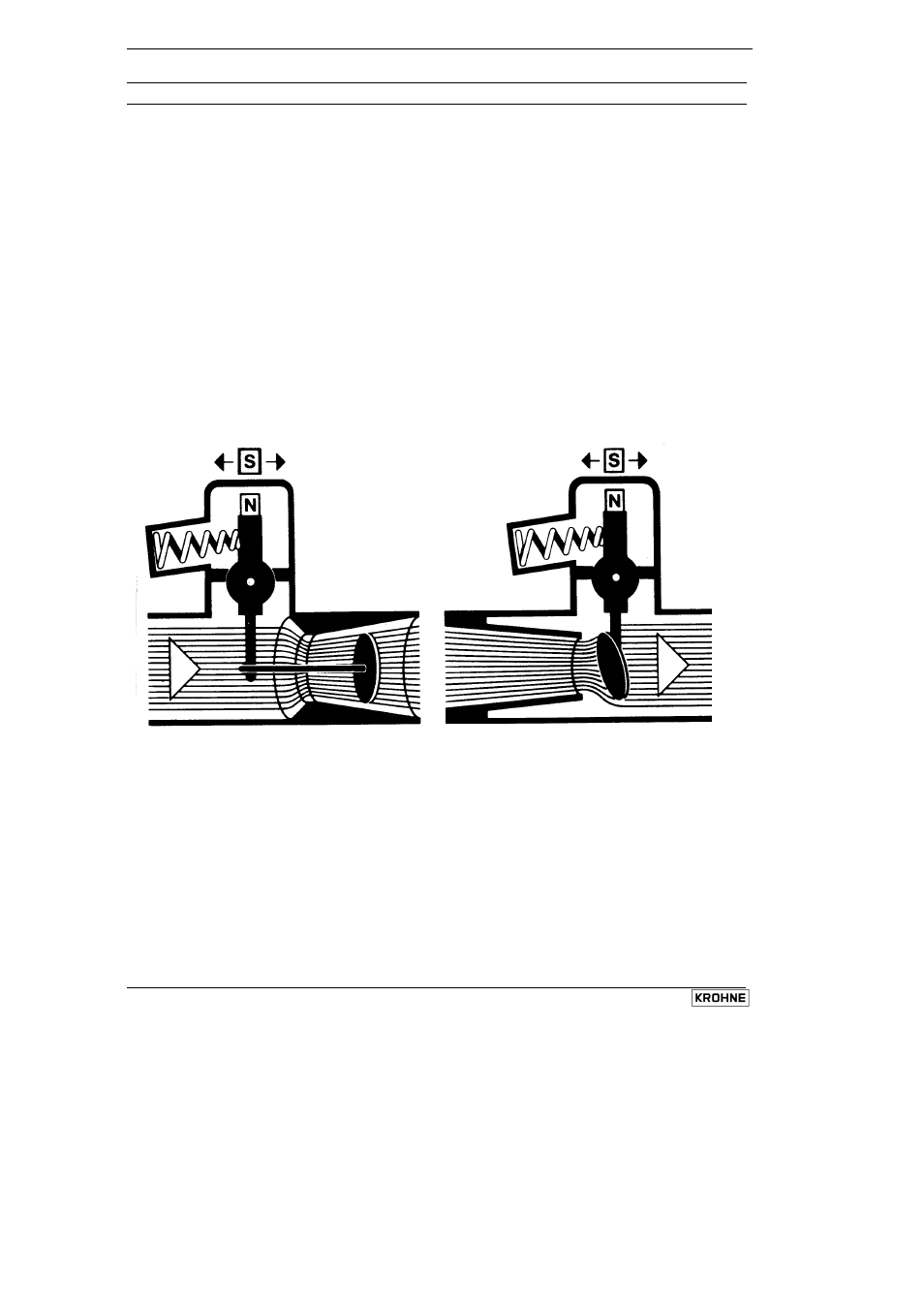

Measuring system C:

A hinged measuring disc moves freely in the axis of a tapered tube (DW 181, DW 182 only). At

flowing conditions, the system adjusts so that the force acting on the disc is in equilibrium with the

spring force. Each flow rate thus corresponds to a particular position of the indicator and

simultaneously actuates the limit switches.

Measuring system E:

Instead of being located in a tapered tube, this system incorporates a nozzle (DW 181, DW 182

only) to increase the flow velocity. This version is particularly suitable for liquids with solids

content.

Measuring system P

(DW 183 and 184 flow switches only)

This is used for large nominal pipe diameters (DW 183, DW 184). It is similar to system E but

does not require a nozzle.

Measuring system C

Measuring system E (P)

8.2 DW

183

The model DW 183 is recommended for pipe diameters from DN65…200, which can be installed in

any position in the piping. The diameter of the measuring tube depends on the flow to be measured

and the connection is adapted to that of the piping.

The maximum flow rate is 4 m/sec. The DW 183 is available in the “N” (carbon steel) “R” (stainless

steel-coated carbon steel) or “RR” (stainless steel) versions. The indicator and the switches are the

same as those used in the standard model.

For instruments without flow indication, the scale ratio between min. and max. range values is

1:2.5. A scale ratio of 1:4 is possible if required by the two limit switches. For instruments with flow

indication, the scale ratio is 1:4.

For vertical installation, the position of the installation and the flow direction should have been

indicated in the order for calibration in order to take the weight of the disc into account.