Installation, 6 mounting of inline version – KROHNE OPTISENS OAS 2000 EN User Manual

Page 23

INSTALLATION

3

23

OPTISENS OAS 2000

www.krohne.com

07/2010 - MA OAS 2000 R02 en

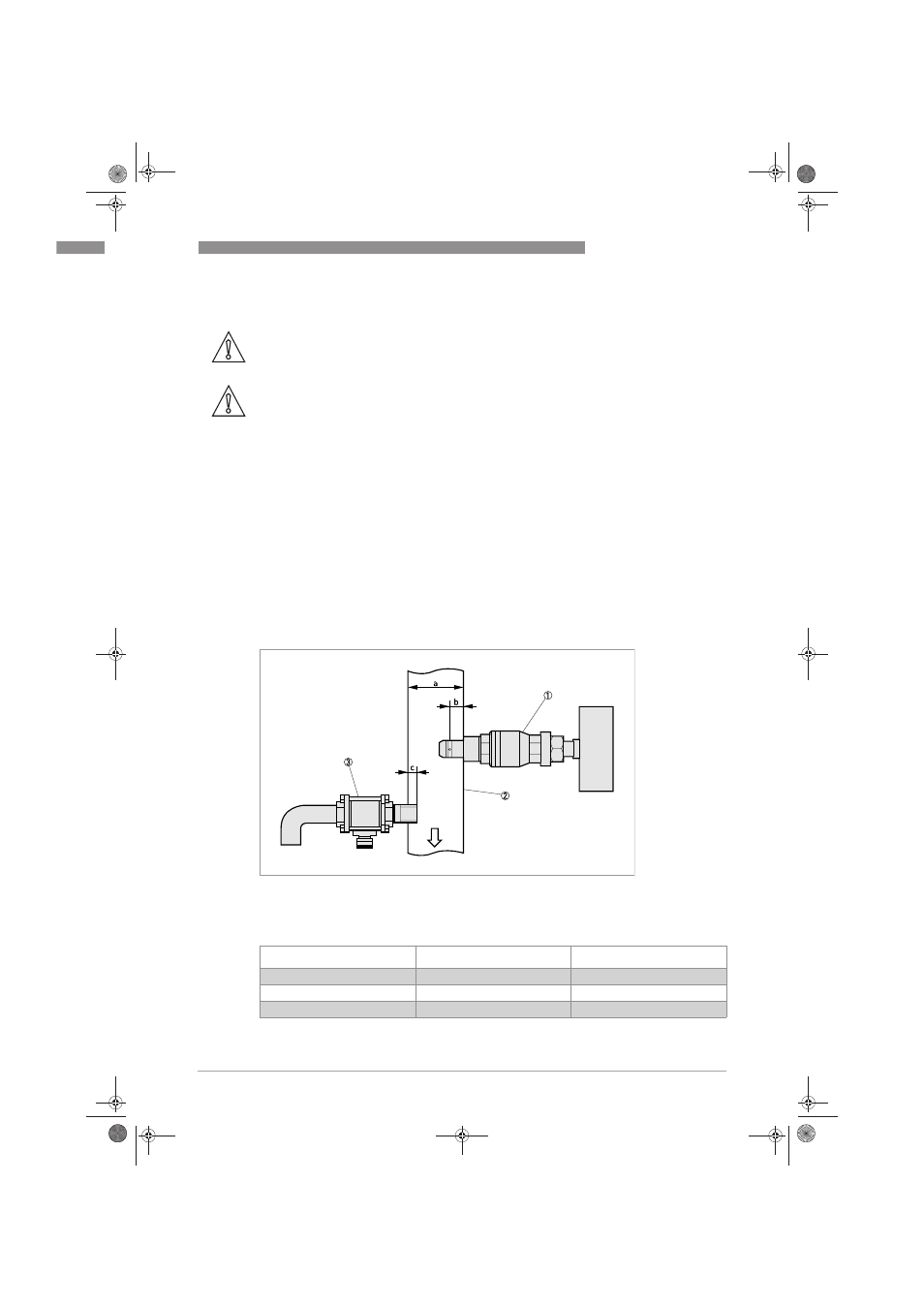

3.6 Mounting of inline version

The inline sensor is mounted through a ball valve to make it possible to remove the sensor

under pressure. Make sure there is at least 260 mm / 10.2" free space to remove the sensor

from the valve. The sensor shall be mounted in a place where the process pressure is at least

1 bar. In horizontal pipes the sensor shall be mounted from the side or from below to avoid

disturbance from air bubbles.

The sensor is designed to be mounted in a right angle to the process flow. The smallest process

pipe diameter to mount the sensor is 80 mm / 3.1". The measure gap must be at least 5 mm /

0.2" from the pipe wall. If a sample outlet is used it must reach at least 20 mm / 0.8" into the

pipe.

Place the sensor at a location where there is no risk for it to get damaged. When the OAS 2000

inline is used outdoors, it shall be mounted with a sun and rain protective hood.

CAUTION!

Be aware that the force may be strong when the sensor is mounted under pressure.

CAUTION!

If the following instructions cannot be fulfilled in all parts, the sensor should not be mounted or

dismounted under process pressure.

Figure 3-6: Mounting of sensor and sample outlet

1 Inline sensor with ball valve

2 Process pipe

3 Sample outlet

Dimensions [mm]

Dimensions [inches]

a

min. 80 mm

min. 3.1"

b

min. 5 mm

min. 0.2"

c

min. 20 mm

min. 0.8"

.book Page 23 Friday, July 2, 2010 1:49 PM