Using the transducer with other equipment, Maintenance, Warranty provisions – In-Situ PXD-461 Operators Manual User Manual

Page 3

Page 3 of 4

Using the Transducer with Other Equipment

The transducer provides a current output that is proportional to the

applied pressure. This output is a 4-20 mA change corresponding to a

full-scale change in pressure. The voltage required by the transducer

is 11.6–40 (maximum) VDC.

Any data logger that provides the necessary voltage and can read the

4-20 mA current output can be used with the transducer. To insure

accuracy, power should be applied for a minimum of 50 milliseconds

prior to any reading.

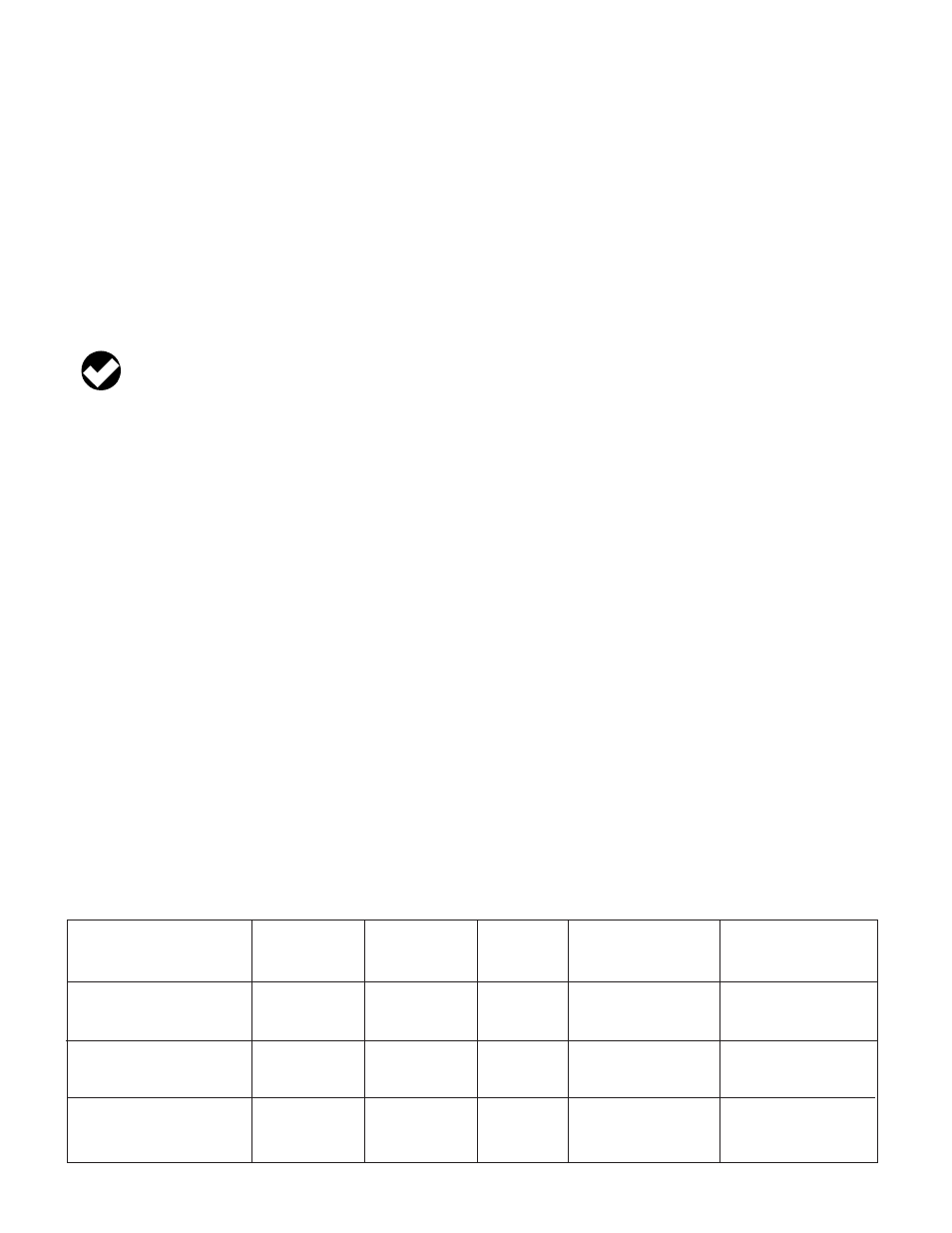

Transducer wiring is shown in the table below by cable type.

Mating connectors must be ordered separately from In-Situ, Inc. A kit

with wiring diagrams is available. Do not use any other type of

connector as this will compromise the integrity of waterproof opera-

tion. Also, remember that the vent tube in the cable must remain

unobstructed to assure that the transducer is insensitive to barometric

pressure changes.

Maintenance

Filter

A small mesh filter protects the pressure sensor from dirt and other

foreign objects. It is held in the end of the NPT threads by a small star

washer and can be seen when the nosecone is removed. The filter

appears opaque when clean. If it becomes clogged with silt, try

flushing it gently with a couple of squeezes from a water bottle. If this

doesn’t do the trick, contact Customer Service.

Nose Cone

If the holes in the nose cone become plugged, take the nose cone off

and clean the holes with a swab or brush. To replace the nose cone

on the PXD-261, first put the wavy spring washer over the threads,

then screw on the nose cone hand-tight.

Cable

The transducer’s Quick-Connect cable connector permits easy cable

removal when changing to a different cable, installing the transducer

in a pipe fitting, or storing the probe. Cable is available in standard

and custom lengths of vented polyurethane or FEP*, or non-vented

HDPE.

Take care to protect the cable from the sharp edges of well casings.

All cables are internally sealed to protect the transducer in the event

that the cable is cut. Don’t attempt to repair, splice, or seal any cuts

without first consulting In-Situ Technical Support personnel.

Vent Tube (Vented Cable)

PSIG pressure sensors are designed to be insensitive to barometric

pressure changes. A vent tube in the cable assures that atmospheric

pressure is the reference pressure to the sensor diaphragm. For

proper operation the vent tube should not be bent, kinked, or

blocked. Such obstructions will cause barometric pressure fluctua-

tions to appear in measurements, and may also introduce large,

varying errors due to thermal expansion and contraction of air

within the vent tube and probe body.

Calibration

Accuracy can be adversely affected by improper care and handling,

exceeding operating pressure and temperature limits, physical

damage or abuse. Annual recalibration is recommended.

Contact In-Situ Customer Service for information on recalibration.

Warranty Provisions

In-Situ Inc. warrants the PXD-261 and PXD-461 for one year from date of

purchase by the end user against defects in materials and workmanship

under normal operating conditions. To exercise this warranty contact Techni-

cal Support at the phone or e-mail address below for a return material

authorization (RMA) and instructions. Complete warranty provisions are

posted on our website at www.In-Situ.com.

In-Situ Inc. does not warrant the transducer against dam-

age caused by use with devices not provided by In-Situ.

Source Double

Return Double

Cable

Source (+)

Return (–)

Ground

Connector (+)

Connector (–)

4-conductor

Yellow

Brown

Shield

Yellow & Orange

Brown & Red

Non-vented

(Pin 6)

(Pin 5)

(Pin 4)

6-conductor Poly

Brown

Black

Shield

Black & White

Brown & Red

Vented (RuggedCable

™

)

(Pin 6)

(Pin 5)

(Pin 4)

6-conductor FEP

Yellow

Black

Shield

Yellow & Orange

Black & Brown

Vented (RuggedCable

™

)

(Pin 6)

(Pin 5)

(Pin 4)