Introduction – DeFelsko PosiTector UTG v.2.2 User Manual

Page 2

Introduction

Introduction

2

The PosiTector UTG ME is a hand-held Ultrasonic

Thickness Gage that uses the non-destructive ultra-

sonic pulse-echo principle to measure the wall thick-

ness of a wide variety of materials. The default and

most common setting for the PosiTector UTG is

multiple-echo (ME) mode. In ME mode the Gage

measures the metal thickness of a painted structure,

disregarding the paint thickness. The user can

switch the gage to single-echo mode by selecting SE

Mode from the Gage menu (see pg.15).

The probe (a single element contact transducer)

transmits an ultrasonic pulse into the material to be

measured. This pulse travels through the material

towards the other side. When it encounters an inter-

face such as air (back wall) or another material, the

pulse is echoed back to the probe. The time required

for the pulse to propogate through the material is

measured by the Gage, represented as t

1

and t

2

below.

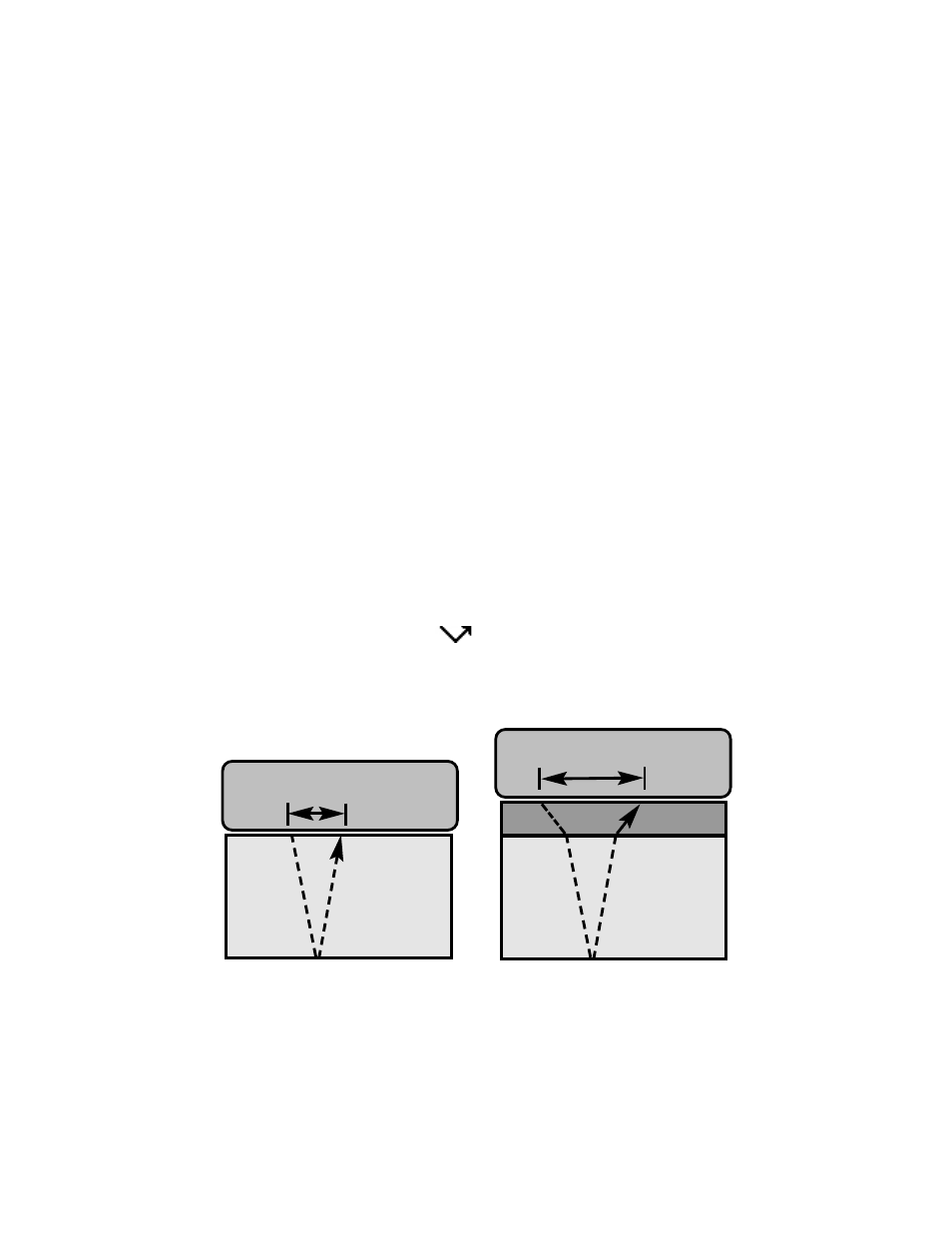

In single-echo mode (see Figure 1) the Gage

determines thickness by measuring t

1

(uncoated) or

t

2

(coated), dividing it by two and then multiplying by

the velocity of sound for that material (steel).

steel

coating

steel

2

t

>

1

t

For uncoated materials t

1

relates directly to material

thickness. When a material is coated the propaga-

tion time is increased and is shown above as t

2

.

Coatings such as paint have a slower velocity of

Figure 1

2

t

1

t

Probe

Probe