0 installation, 0 purpose, Maximum capacities - mscfd – Van Air Systems PLD 8-7.2 / 36-7.2 User Manual

Page 2: 1 location

MODEL

NO.

PLD 8-7.2

PLD 12-7.2

PLD 16-7.2

PLD 20-7.2

PLD 24-7.2

PLD 30-7.2

PLD 36-7.2

PAGE 2

2.0 INSTALLATION

CAPACITY: The chart below indicates the maximum fl ow rate

through the dehydrator for a 24 HOUR period. To calculate the

capacity for a rate per minute just multiply the MSCFD RATE (from

chart ) by 0.6944 example:

A PLD 12-7.2 operating at 100 PSIG has a maximum MSCFD rate

of 132. To fi gure the SCFM multiply 132 MSCFD x 0.6944 which

equals 92 SCFM

NOTE: This is the MAX instantanious fl ow that

can be processed through the dehydrator without

deterioration of the drying performance.

OPERATING PRESSURE: More gas can be processed through the

dehydrator at higher pressures. Locate the dehydrator at the highest

practical pressure, but do not exceed the maximum rated working

pressure of the dehydrator. Refer to the capacity chart located below.

AFTERCOOLING: If the gas being processed has been compressed

mechanically, an aftercooler, fi nned tubing or extended run of piping

will usually be necessary to reduce the inlet gas temperature to the

dehydrator.

MAXIMUM CAPACITIES - MSCFD

1,000 STANDARD CUBIC FEET PER DAY

600 PSIG

377

709

1108

1778

2522

4001

6385

500 PSIG

315

594

928

1489

2112

3350

5346

400 PSIG

254

479

748

1200

1701

2700

4307

300 PSIG

193

363

567

910

1291

2049

3269

200 PSIG

132

248

387

621

881

1398

2230

100 PSIG

70

132

207

332

471

747

1191

MAXIMUM

WORKING

PRESSURE

720 PSIG

720 PSIG

720 PSIG

720 PSIG

720 PSIG

720 PSIG

720 PSIG

PART

NO.

80-1326

80-1328

80-1330

80-1332

80-1334

80-1466

80-1308

720 PSIG

450

848

1325

2126

3014

4783

7631

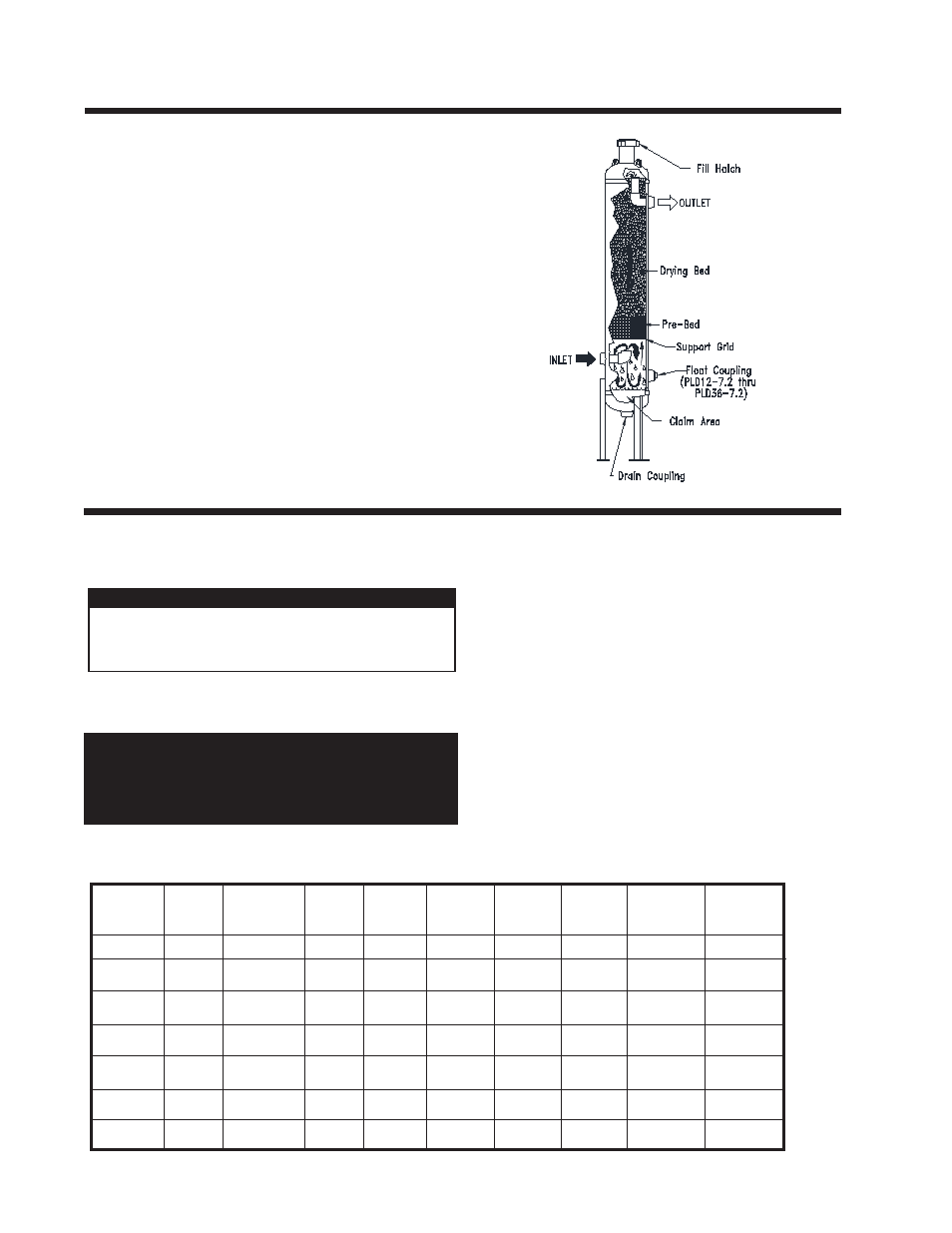

1.0 PURPOSE

A Pipeline Dehydrator removes the water vapor (humidity) pres-

ent in the gas stream. The process cleans and dries the gas as it

fl ows through a vessel which is fi lled with a special drying agent

(desiccant). The dehydrator operates automatically. There are no

moving parts and no external source of power is required.

"Wet" natural gas enters the lower portion of the dryer where liquid

water and solid particles are separated by gravity and fall to the

bottom of the vessel. The gas moves upward through the prebed

and drying bed of Van Gas desiccant tablets. The tablets attract

and absorb moisture from the gas as it fl ows through the desiccant

bed. The tablets dissolve gradually as they absorb the moisture

and the liquid falls to the bottom of the vessel. The liquid run off in

the prebed creates an extended surface area capable of removing

additional moisture from the gas. This conserves the absorbent

desiccant tablets. The "dry" natural gas fl ows through the dryer

outlet.

The solution of dissolved desiccant and water that falls into the

claim area at the bottom of the vessel must be drained regularly to

prevent the vessel from fl ooding. An automatic drain valve can be

installed to prevent the vessel from fl ooding.

2.1 LOCATION

The ability of a dehydrator to dry natural gas is dependent on

the correct location of the unit. Temperature and pressure are

the keys to selecting the proper location.

INLET GAS TEMPERATURE: Lower inlet gas temperatures will

result in a lower moisture content at the outlet of the dehydrator.

Locate the dehydrator at the point where temperature is the lowest.

ALWAYS PROCESS THE GAS THROUGH THE

DEHYDRATOR AT THE LOWEST TEMPERATURE

AND THE HIGHEST PRESSURE.

IMPORTANT

CAUTION

The gas temperature should not exceed:

100°F for GASDRY PRIME

80°F for GASDRY PEAK

100°F for GASDRY MAX