Van Air Systems AHP High Pressure Alloy Filter Series IOM User Manual

Ahp series compressed air filters, Installation, operation & maintenance instructions, Warnings

PAGE 1

WARNINGS

DO NOT REPLACE ANY ITEM ON FILTER WHILE IT IS PRESSURIZED.

DO NOT OPERATE A LEAKING FILTER. TAKE FILTER OUT OF SERVICE IMMEDIATELY.

DO NOT OPERATE ABOVE MAXIMUM WORKING PRESSURE (MWP) AT MAXIMUM OPERATING TEMPERATURE (°F).

•

•

•

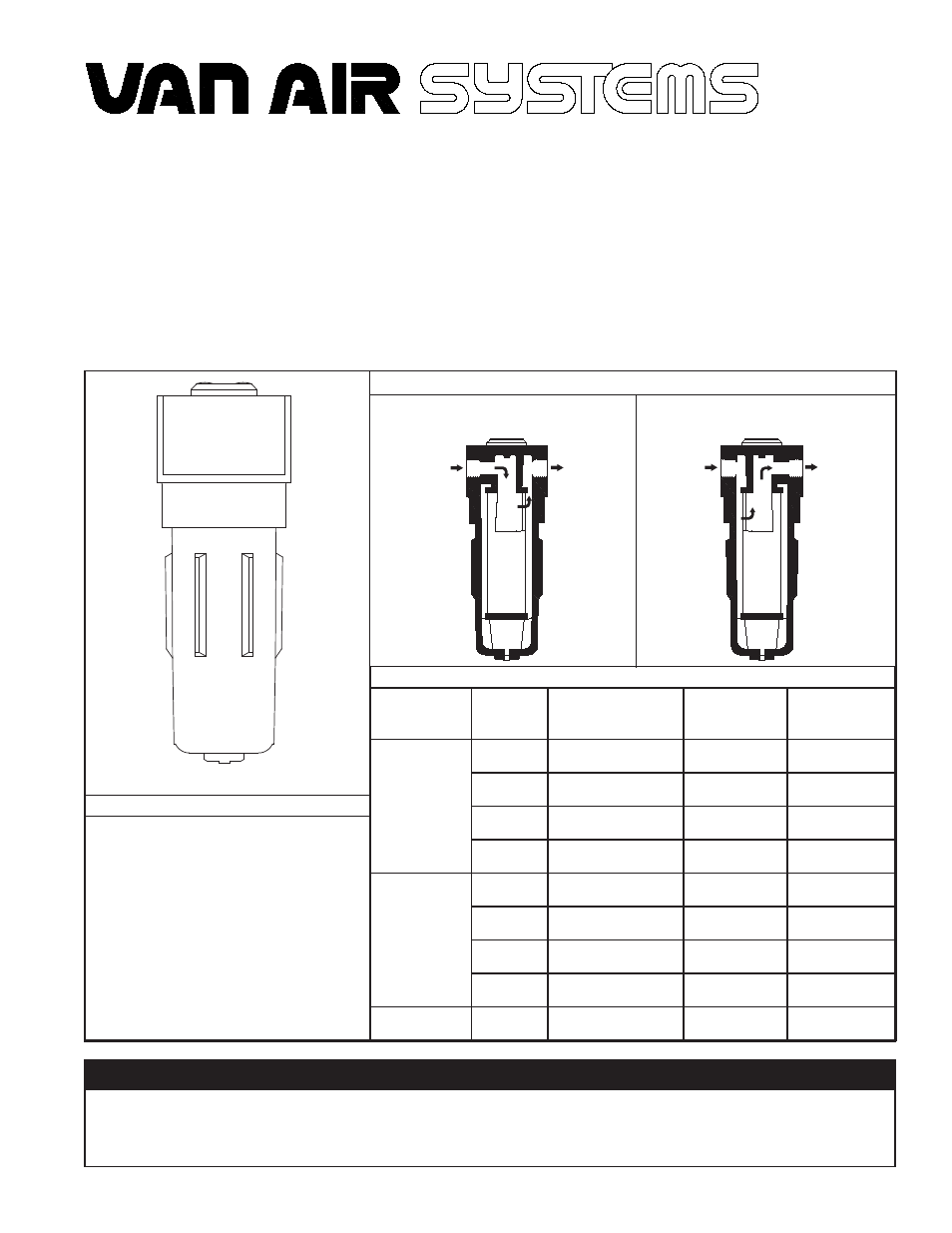

(COALESCING)

IN/OUT

(PARTICULATE)

OUT/IN

FEBRUARY 2012

P/N 32-0313

REV A

FLOW DIRECTION THROUGH ELEMENT

OUTLET

INLET

PRODUCT PURPOSE & FUNCTION:

Van Air's AHP series filters are designed to remove contaminants from compressed air systems. Available in 1/4" to 2" con-

nection sizes and flow capacities from 94 to 1882 scfm (at MWP @ 725 psig) in 8 housings and 9 filtration grades, the AHP series can

remove oil aerosols, oil vapors, water and particulates. Housings are made of cast aluminum and coated with black high temperature

paint for corrosion resistance. All units include push-on elements with durable polyester drain layer (except RD grade).

OPERATING CONDITIONS

MAXIMUM WORKING PRESSURE

All Models

OPERATING TEMPERATURE

Minimum

Maximum

MAXIMUM RECOMMENDED INLET TEM-

PERATURE

AA, A, RAA, RA, RB, and RC Series

B Series

C Series

RD Series

725 PSIG

35°F

248°F

225°F

175°F

125°F

80°F

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

AHP SERIES

COMPRESSED AIR FILTERS

INLET

OUTLET

FILTRATION GRADES

APPLICATION

ELEMENT

GRADE

PURPOSE

NOMINAL

PARTICLE

REMOVAL

ELEMENT FLOW

DIRECTION

OIL

REMOVAL

(LIQUIDS)

AA

Extra Coarse

Coalescing

25.00 μ

IN/OUT

A

Coarse

Coalescing

5.00 μ

IN/OUT

B

General Purpose

Coalescing

1.00 μ

IN/OUT

C

High Efficiency

Coalescing

0.01 μ

IN/OUT

PARTICULATE

REMOVAL

(SOLIDS)

RAA

Extra Coarse

Particulate

25.00 μ

OUT/IN

RA

Coarse

Particulate

5.00 μ

OUT/IN

RB

General Purpose

Particulate

1.00 μ

OUT/IN

RC

High Efficiency

Particulate

0.01 μ

OUT/IN

OIL VAPOR

REMOVAL

RD

Vapor Absorbing

0.01 μ

OUT/IN