Van Air Systems PD-2 Pressure Differential Gauge Kits User Manual

Pd-2, pd-2/sw, pd-2/ht, & pd-2/sw ht, Pressure differential gauge kits

OCTOBER 2004

P/N 30-0602 REV A

INSTALLATION, OPERATION, AND MAINTENANCE INSTRUCTIONS

FOR

PD-2, PD-2/SW, PD-2/HT, & PD-2/SW HT

PRESSURE DIFFERENTIAL GAUGE KITS

RECOMMENDED FOR INSTALLATION ON F101 SERIES FILTERS

SPECIFICATIONS

INSTALLATION

WARNING

CAREFULLY READ THESE INSTRUC-

TIONS BEFORE INSTALLING THE

PRESSURE DIFFERENTIAL KIT.

MAKE SURE THAT THE COMPONENT

OR PIPING IS DEPRESSURIZED

BEFORE INSTALLING THE PRESSURE

DIFFERENTIAL KIT.

COMPLY WITH ALL APPLICABLE

ELECTRICAL CODES IF INSTALLING A

PD-2/SW OR PD-2/SW HT KIT.

Completely depressurize the piping and

component that the kit is to be installed on.

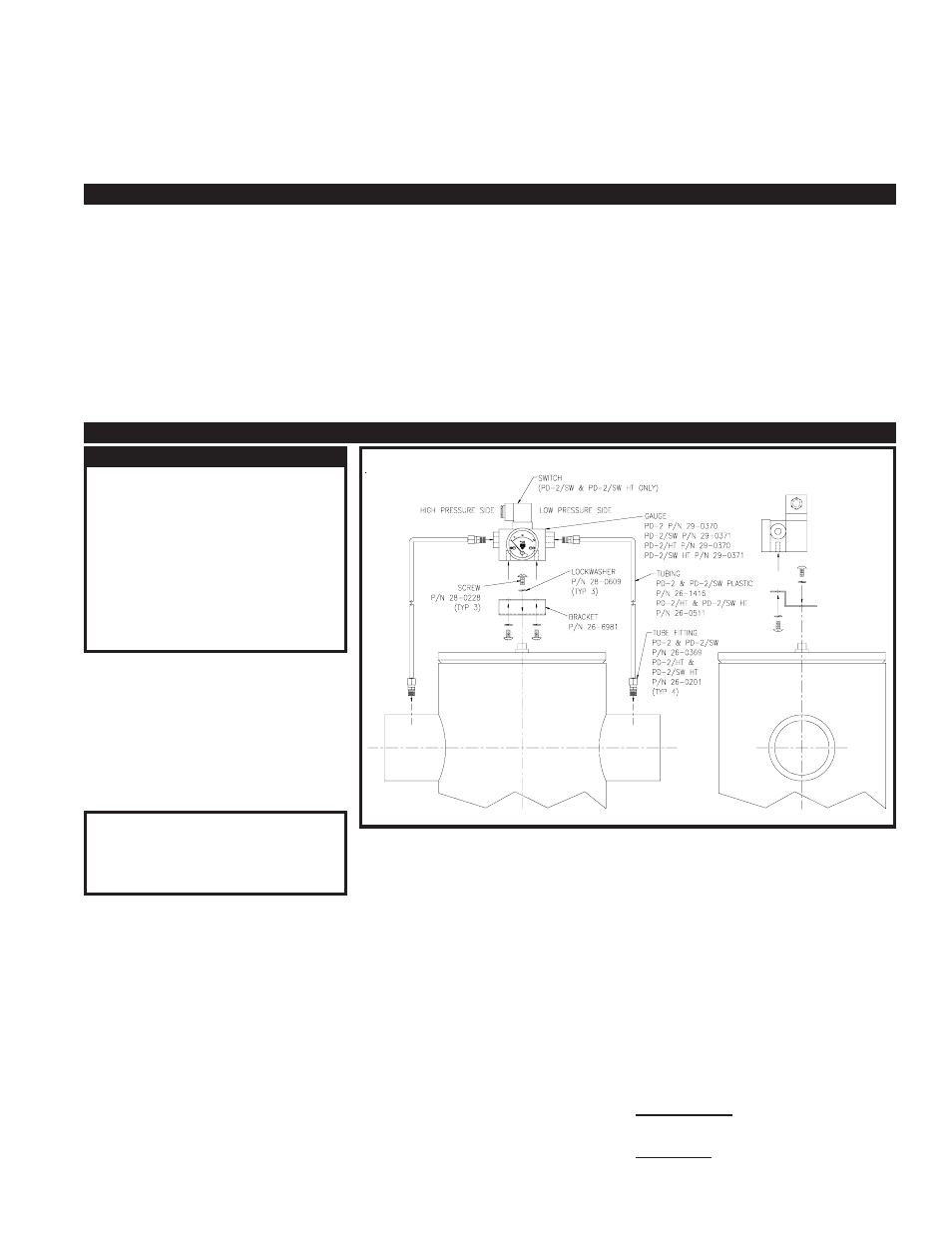

Figure 1 shows a typical assembly/installation

of the PD-2 series pressure differential gauge

on a VAN AIR F101 series filter housing.

Mount the gauge on the mounting bracket.

Use the fasteners provided with the kit. Mount

the kit to the desired surface.

IMPORTANT

To ensure an accurate reading, make

sure that both tubing lines to the

gauge are equal in length. Use as few

bends as possible in the tubing lines.

Install the necessary tubing from the inlet side

of the vessel or piping to be measured to the

HIGH PRESSURE port of the gauge. Use the

tubing and fittings as shown in FIGURE 1. Use

pipe sealant on all threaded pipe connections.

Complete the tubing connection from the outlet

side of the vessel or piping to be measured to

the LOW PRESSURE port of the gauge. Use

the tubing and fittings as shown in FIGURE 1.

Use pipe sealant on all threaded pipe connec-

tions.

SWITCH CONNECTIONS AND

ADJUSTMENTS (PD-2/SW PD-2/SW HT)

CONNECTING THE SWITCH

The gauges are equipped with an electric

switch. This switch can be used to activate

Disconnect the tubing from the HIGH

PRESSURE port on the gauge.

Using a clean, dryer source of compressed

air and a pressure regulator slowly apply

pressure to the HIGH PRESSURE port until

the gauge reads the desired set point.

Loosen the adjustment screw on the top of

the gauge. Use a voltmeter to check the

position of the switch. Slide the adjustment

screw until the switch is closed at the

desired pressure on the gauge. NOTE, The

screw may be difficult to slide. This is

normal.

Once the switch is properly set, tighten the

adjustment screw. Reconnect the sample

tubing to the HIGH PRESSURE port.

PD-2 KIT p/n 84-0129

MAX. OPERATING PRESSURE ..................... 200 PSIG

MAX. OPERATING TEMPERATURE .............. 150

O

F

OPERATING RANGE ...................................... 0-15 PSID

GAUGE DIMENSIONS..................... 4"L, 1.5"W, 2.0625"H

PRESSURE PORT CONNECTIONS .............. 1/8" NPT

PD-2/HT KIT p/n 84-0130 (Same as 84-0129 except)

MAX. OPERATING PRESSURE ..................... 3000 PSIG*

MAX. OPERATING TEMPERATURE .............. 175

O

F*

*NOTE: SEE F101 SERIES FILTER RATINGS.

PD-2/SW KIT p/n 84-0131

MAX. OPERATING PRESSURE ..................... 200 PSIG

MAX. OPERATING TEMPERATURE .............. 150

O

F

OPERATING RANGE ...................................... 0-15 PSID

GAUGE DIMENSIONS.....................4"L, 2.375"W, 3.75"H

PRESSURE PORT CONNECTIONS .............. 1/8" NPT

CONDUIT PORT CONNECTION ................... 1/2" NPT

SWITCH RATINGS

SET POINT (adjustable)0-15 PSID

ELECTRICAL ............... 110V/1PH/60Hz, 1/2 AMP, 50 WATTS

TYPE ............. SPST (Single Pole Single Throw)

an alarm to alert personnel that the

pressure differential across the measure

piping or vessel has reached an unaccept-

able level. The set point of the switch is

adjustable.

The valve is tapped with 1/2" NPT conduit

connections. Conduit can be run from the

gauge to the alarm panel.

Make the necessary wiring connections

from the gauge to the alarm panel.

Reference FIGURE 1.

ADJUSTING THE SWITCH SET POINT

The gauge switch is adjustable. It should

be set at the pressure differential reading

that you want to activate the alarm device.

If the gauge is installed on a filter set it at

the recommended element replacement

pressure differential, reference filter manual

for this setting.

Make sure that the piping or vessel that the

gauge is connected to is depressurized.

FIGURE 1 INSTALLATION

PD-2/SW HT KIT p/n 84-0211 (Same as 84-0131 except)

MAX. OPERATING PRESSURE ..................... 3000 PSIG

MAX. OPERATING TEMPERATURE .............. 175

O

F

MAINTENANCE: PER GAUGE INSTRUC-

TIONS.

WARRANTY: PER TERMS AND CONDI-

TIONS OF SALE.