Van Air Systems ID15/SW User Manual

In-line desiccant dryer model id15/sw, Installation instructions, Replacement parts

ZZZYDQDLUV\VWHPVFRP

0IGLQ86$

&$3$&,7<6&)0#36,*0:336,*

0D[,QOHW7HPSHUDWXUH)

)25'5<,1*&2035(66('$,525*$6

0RGHO1R,',1'

&DUWULGJH1R06

%

$

,1

287

1/4" BALL VALVE

2950 Mechanic Street

Lake City, PA 16423-2095

Phone: 814-774-2631

Fax: 814-774-3482

www.vanairsystems.com

March 2009

P/N: 432-00106-E

INSTALLATION INSTRUCTIONS

IN-LINE DESICCANT DRYER

MODEL ID15/SW

VAN AIR PART NUMBER: 38-0125

FOR DRYING COMPRESSED AIR OR GAS TO -40°F PRESSURE DEW POINT

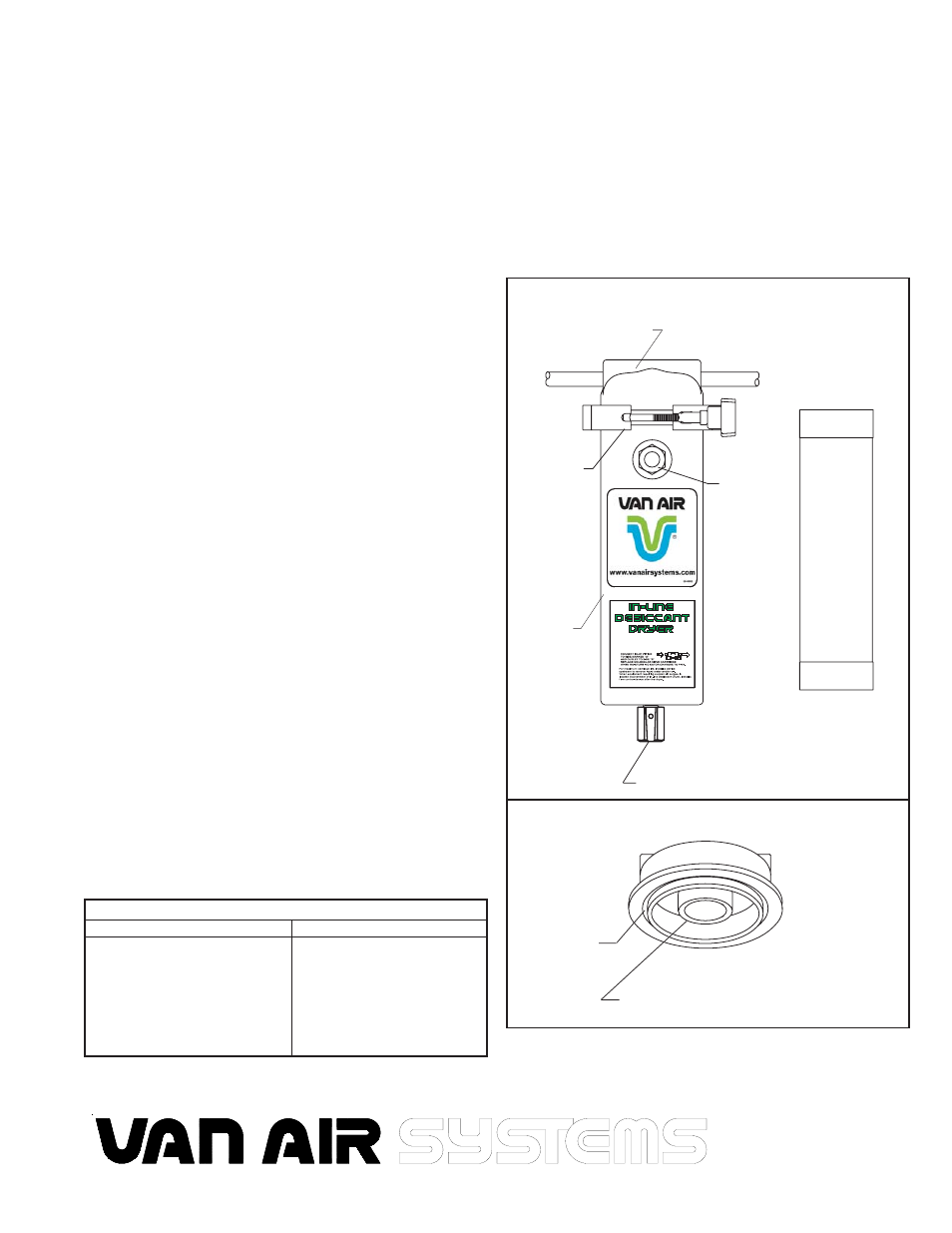

SG-23

SILICA GEL

CARTRIDGE

SIGHT

WINDOW

CLAMP

A

B

BOSS (INSTALL CARTRIDGE HERE)

O-RING

GROOVE

VIEW FROM BOTTOM OF DRYER HEAD

ID15/SW

INLET

1/2" NPT

HEAD

OUTLET

1/2" NPT

BOWL

(NOTE: CARTRIDGE SHIPPED IN BOX

WITH DRYER.)

REPLACEMENT PARTS

DESCRIPTION

DRYER HEAD

DRYER BOWL

SG-23 CARTRIDGE

1/2" NPT SIGHT GLASS

HOUSING O-RING

HOUSING CLAMP

1/4" NPT BALL VALVE

VAN AIR PART NO.

201-00052

201-02000

26-0888

551-00400

475-00235

471-00100

290-00011

WHEN TO REPLACE CARTRIDGE:

Crystals in cartridge as seen through sight window of

housing will change from blue to pink when silica gel in cartridge

is saturated with moisture. Install fresh cartridge when crystals

turn to pink.

INSTALLING ID15/SW DRYER:

Locate dryer as close as possible to equipment to be

protected.

Where condensed moisture is present in the air line, install a

separator with drain valve upstream of dryer.

Install inlet and outlet valves for isolating dryer during

cartridge change.

Check markings on head of vessel; then connect inlet piping

to side marked "A" and outlet to side marked "B".

If there are any sudden air surges downstream of dryer,

install a flow control device after the dryer.

Install SG-23 cartridge as outlined below.

1.

2.

3.

4.

5.

6.

INSTALLING SG-23 CARTRIDGE:

Close dryer inlet and outlet shutoff valve. Slowly open drain

on bottom of bowl until vessel is completely depressurized.

Grasp bottom portion of housing (bowl) with one hand and

turn clamp knob with the other to loosen. Slide clamp down

and off vessel.

Remove used cartridge from head and discard the cartridge.

Remove new cartridge from box and vapor seal bag.

Push new cartridge onto boss of dryer head.

Reinstall bowl and clamp. Make sure that the bowl is tight

against the head and the o-ring is correctly seated in the

groove.

Close the ball valve and slowly repressurize the vessel. If

any leaks occur, depressurize vessel completely and correct

the problem.

1.

2.

3.

4.

5.

6.

7.