Van Air Systems FR-800 User Manual

Page 7

PAGE 7

6.1 DESCRIPTION OF OPERATION

The Prep-40 is a portable skid mounted system consisting of a strainer,

pre-cooler, separator, prefilter, heatless regenerative dryer and an

afterfilter. Wet warm air enters the pre-cooler where it is cooled to a

temperature approcahing ambient. Water is condensed out during

this cooling process. The saturated air and the liquid water proceed to

the inlet of the separator where the liquid water is removed. Then the

saturated air enters the coalescing filter where additional oil and liquid

water is removed. Then the air enters the heatless twin tower dryer where

it moves upward through the desiccant bed. The moisture is adsorbed

onto the surface of the desiccant. Dry air exits the heatless dryer and

passes through the general purpose particulate after-filter where residual

particulate is removed.

This package dryer will take saturated air at 100 psig @ 150°F and reduce

the mositure content to -40°F pressure dew point.

START UP

SECTION 5

OPERATION

SECTION 6

Operate the until NO desiccant dust is visible at the purge valves.

Then the mufflers can be installed.

IMPORTANT

The dryer system must be operated for several hours without

the mufflers after the towers have been filled with desiccant.

This will prevent the mufflers from becoming clogged.

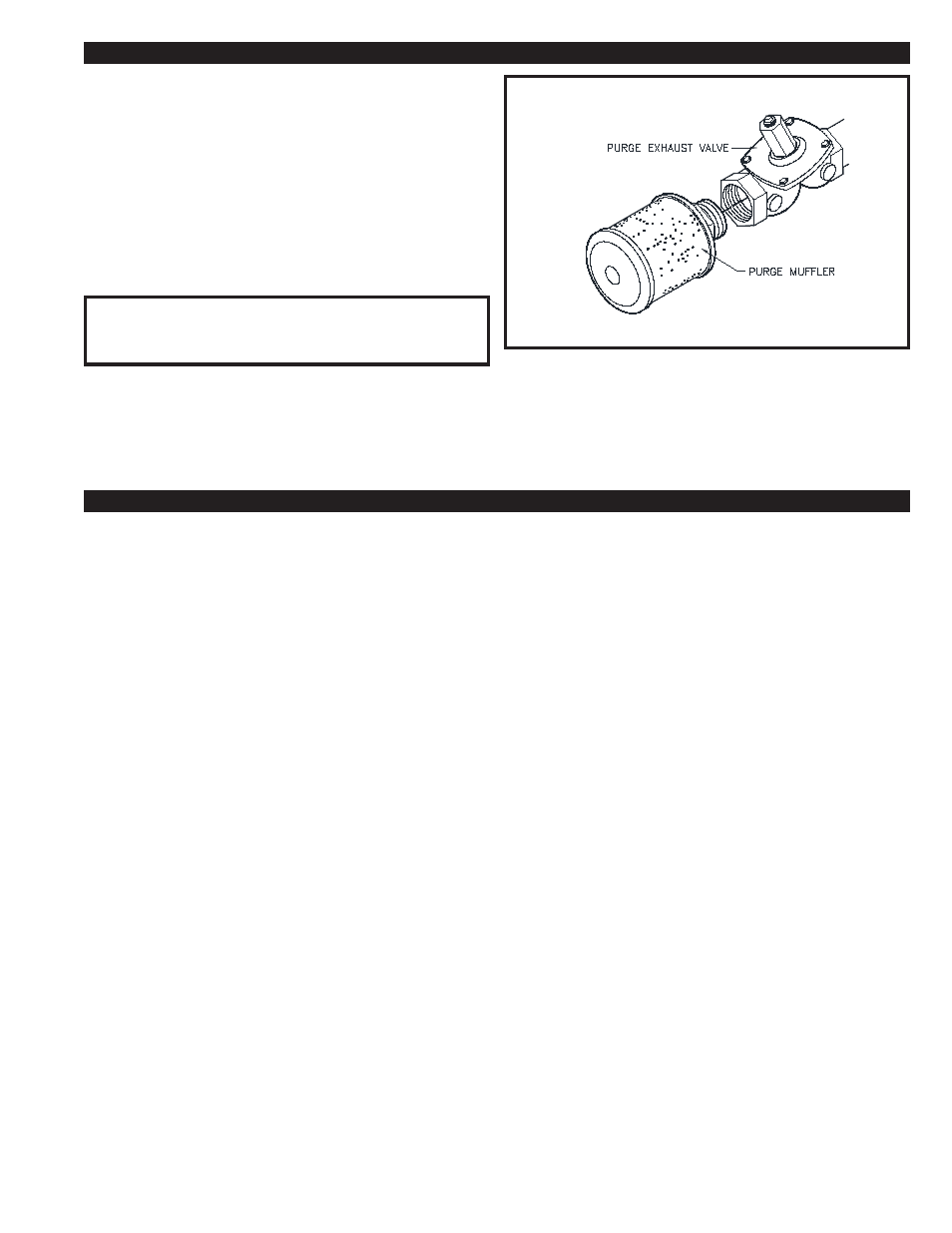

FIGURE 5A PURGE MUFFLER INSTALLATION

5.6 INSTALLING THE PURGE MUFFLERS

To reduce the sound level during purge and tower depressurization,

this dryer system was supplied with mufflers for installation on the

purge exhaust valves.

Mufflers were shipped separately. They should

NOT be installed until

the dryer system has been operated for several hours. From

desiccant installation, some dust may be present in the desiccant

towers. Operating the dryer system with the mufflers installed

immediately after the towers have been filled with the desiccant or

during initial start up may cause the mufflers to clog.

The dryer operation consists of four stages; REPRESSURIZATION,

CHANGEOVER/DEPRESSURIZATION, DRYING and

REGENERATION.

6.2-1 REPRESSURIZATION STAGE

Repessurization occurs in the off-stream (regenerating) tower.

Repessurization must occur before tower changover to reduce shock

to the desiccant and the possibility of downstream pressure spikes.

Pilot valve SV1 or SV2 de-energizes causing the purge valve on the

off-stream (regenerated) tower to close. The purge air, which was

vented to atomosphere earlier in the cycle, is now used to

repressurize the off-stream tower.

6.2 HEATLESS DRYER PRINCIPLE OF OPERATION

The Heatless Regenerative Air Dryer utilizes the pressure swing principle

of operation. The desiccant bed in one tower dries the air stream while

the desiccant bed in the other tower is regenerated.

A purge of dry air is used for tower regeneration. It is taken from the

outlet of the dryer.

The dryer is equipped with a purge metering valve to allow the correct

amount of dry air to flow into the regenerating tower. The heat created

during adsorption of moisture in the drying tower is retained in the desiccant

bed and increases the moisture removal capacity of the purge air.

The timing cycle of the dryer is controlled by two 3-way pilot valves.

A patented shuttle valve system is used to repressurize, changeover,

and depressurize the towers. The inlet transfer valve is controlled by

the pilot valves.

To achieve maximum performance from this dryer, it should be operated

continuously. Operating this dryer for single shift periods may result in

varied outlet dew point performance.

6.2-2 CHANGEOVER/DEPRESSURIZATION STAGE

Tower changeover occurs after the off-stream (regenerated) tower is

pressurized. The SmartRelay signals SV1 or SV2 to open causing pilot

air to be supplied to the opposite side of the inlet transfer valve and

cause exhaust valve to open on regenerative tower. The inlet transfer

valve shuttle will move to the side that has pilot pressure placing the

regenerated tower on-stream. The tower that was on line and drying

the process air is now off-stream.

When the inlet transfer valve changes position, the position indicator

will move.

6.2-3 DRYING AND REGENERATION STAGE

One tower is on-stream (pressurized) drying process air. The process

air passes through the desiccant bed, which adsorbs moisture from

the air.

The regeneration stage of the off-stream tower occurs at the same time

as the drying stage in the on-stream tower. During the regeneration

stage, a percentage of dry air is directed through the desiccant bed

of the offstream tower. The purge air is vented through the purge

valve to the atmosphere.

If pilot valve SV2 is energized, the LEFT tower is drying and if pilot

valve SV1 is energized, the RIGHT tower is drying.