Van Air Systems FR-800 User Manual

Page 14

PAGE 14

10.3 CHECKIING THE 3-WAY PILOT VALVES

(SV1 & SV2) TOWER CHANGEOVER

All 3-way pilot valves have manual override buttons on the top of the

valve. To test SV1 and SV2 do the following:

Make sure the dryer system is pressurized and the Power switch

is in the

OFF position. Both towers should be at full line pressure

Pushing the manual override of SV1 should cause the left tower to

depressurize. Allow the left tower to come back up to full line

pressure. Pushing the manual override of SV2 should cause the

right tower to depressurize. If this does not happen, replace that

solenoid valve.

With the Power switch (SW) in the

ON position and the dryer system

pressurized, monitor the dryer system for one complete cycle. SV1

should be activated when the left tower is in the regeneration stage

(depressurized) from 15 seconds to 5 minutes. SV2 should be

activated when the right tower is in the regeneration stage

(depressurized) from 5 minutes and 15 seconds to 10 minutes.

These two operations can be monitored in one 10 minute cycle.

Reference

FIGURE 6C for dryer timing chart.

If the above responses are not observed, first check to see if power

is being supplied to each solenoid valve when it is supposed to

open. Check the wiring between the SmartRelay and solenoid

valves. If the SmartRelay is not supplying power to the valve as it

should, replace the SmartRelay. If the valve has power but does not

operate, it must be replaced.

OUTPUT DEVICES

Q1 SV1

Q2 SV2

Q3 PL2

Q4 ALARM CONTACT

TROUBLESHOOTING

SECTION 10

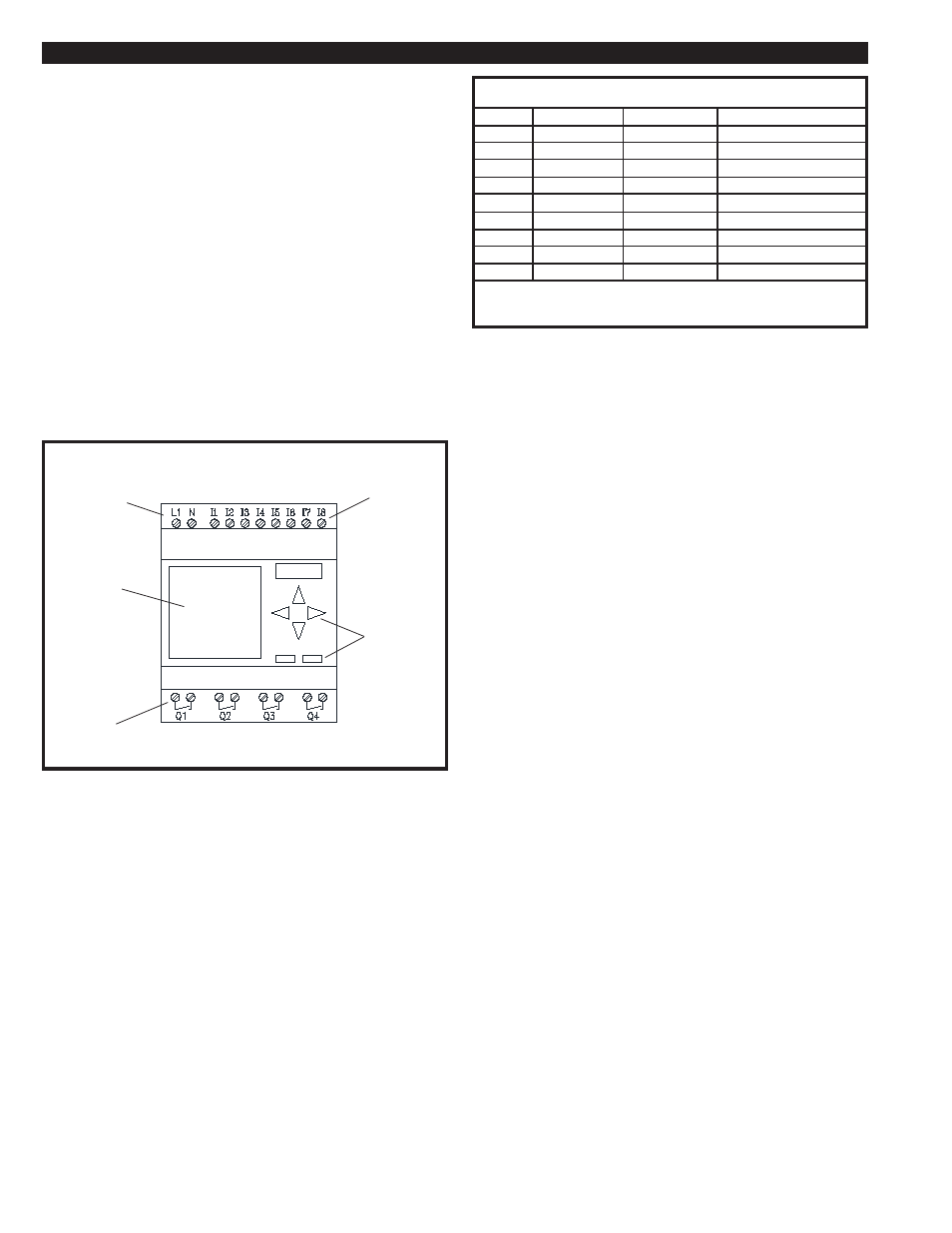

FIGURE 10A SMART RELAY DETAIL

FIGURE 10B INPUT AND OUTPUT LIST

INPUT DEVICES

I1

PS1

I2

PS2

I3

ARPB

I4

SPARE

I5

SPARE

I6

SPARE

I7

SPARE

I8

SPARE

NOTE:

The general alarm contact is a normally open dry contact which is wired to terminals #16

and #17.

10.2A TESTING THE INPUT DEVICES

The input devices supply a 120VAC signal to the SmartRelay. See

FIGURE 10B for a list of the input devices.

The input devices can be easily tested for proper operation. With

power to the control box, set the Power switch to the ON position.

Press the Alarm Reset Pushbutton and verify that there is

120VAC between terminals N and I3 on the Smart Relay. If there

is no voltage, replace the Alarm Reset Pushbutton.

The pressure switches monitor the failure to switch option. The

inputs from the pressure switches (PS1, PS2) can be observed

while the dryer system is in operation. Any time there is more

than 30 psig pressure in the left tower, pressure switch (PS1)

should supply a 120VAC signal to Smart Relay terminal I1. Any

time there is more than 30 psig pressure in the right tower,

pressure switch (PS2) should supply a 120VAC signal to S

martRelay termial I2. If either of the pressure switches does not

respond as previously explained, check the wiring to the pressure

switch. If the wiring and device are good, theSmartRelay is faulty

and should be replaced. Reference

FIGURE 10D WIRING

DIAGRAM for wiring and terminal numbers.

10.2B TESTING THE OUTPUT DEVICES

The SmartRelay’s outputs are 120VAC. See

FIGURE 10B for a

list of the dryer system output devices.

To check output devices SV1 and SV2, follow the procedure in

SECTION 10.3.

INPUTS

POWER

LCD

DISPLAY

CONTROL

BUTTONS

OUTPUTS

10-2 CHECKING THE SMARTRELAY

The control system consists of three different control systems:

1. The SmartRelay

2. Input devices (120VAC components)

a. Pressure switches

b. Alarm Reset push-button

d. Power switch

3. Output components

a. Pilot valves

b. Lights

c. General alarm contact

The SmartRelay controls the cycling of the dryer system. The

program logic is stored on an electrically erasable non-volatile EE-

PROM. Loss of power will not cause loss of the program.

If the LCD display on the SmartRelay is not lit, the SmartRealy is not

operating. If this occurs, check fuse 1FU and replace as needed.

If there is power to the SmartRelay and is still does not function,

consult factory.

See

SECTION 10.2A and 10.2B for procedures to verify the

operation of the input and output devices.