Star Water Systems HCP05 User Manual

Page 4

6

95 North Oak Street • Kendallville, IN 46755 • © 2014 Star Water Systems. All rights reserved.

7

95 North Oak Street • Kendallville, IN 46755 • © 2014 Star Water Systems. All rights reserved.

TROUBLESHOOTING

Before ANY work with the pump, SHUT OFF the electrical supply and ball valves #1 and #2 to

prevent electrical shock and water damage.

Problem

Cause

Correction

Pump does not start or shuts

down,

No power supply.

Connect the electricity supply.

Incorrect voltage.

Pump is 115 Volt only.

It will not start with 230V supply.

Incorrectly plumbed.

Confirm FIG 1 installation is correct.

Confirm ball valves #1 and #2 are open

in suction and discharge. Confirm ball

valve #3 is closed on bypass.

Blocked inlet

Check if pump suction inlet screen is

blocked. See FIG 5.

Insufficient water supply

Insure water source is providing

sufficient water.

Pump starts when no water is

consumed.

Pipe leaking.

Insure all threads have 3 wraps of

Teflon tape + hand tight + 1/2 turn with

wrench.

Tank pressure is low.

See FIG 3 to check and add air

pressure to the tank.

Air in the system.

Insure all threads have 3 wraps of

teflon tape + hand tight + 1/2 turn with

wrench. Re-prime unit.

Pump does not shut down

when water is not consumed.

Blocked check valve.

See FIG 4. Confirm check valve is free

of debris and functions freely.

MAINTENANCE REqUIREMENTS

• Pressure Tank Charge – should be checked

every 3 months to confirm tank air pressure. See

FIG 3 for description to check air pressure.

Note – tank pressure should be set

approximately 5 psi higher than the expected

incoming pressure.

• Internal Check Valve – if Teflon tape or debris

enters into the pump cavity, the operation of the

internal check valve can be restricted. This may

create an erratic or poor performance with the

pump. To clean the check valve see FIG 4.

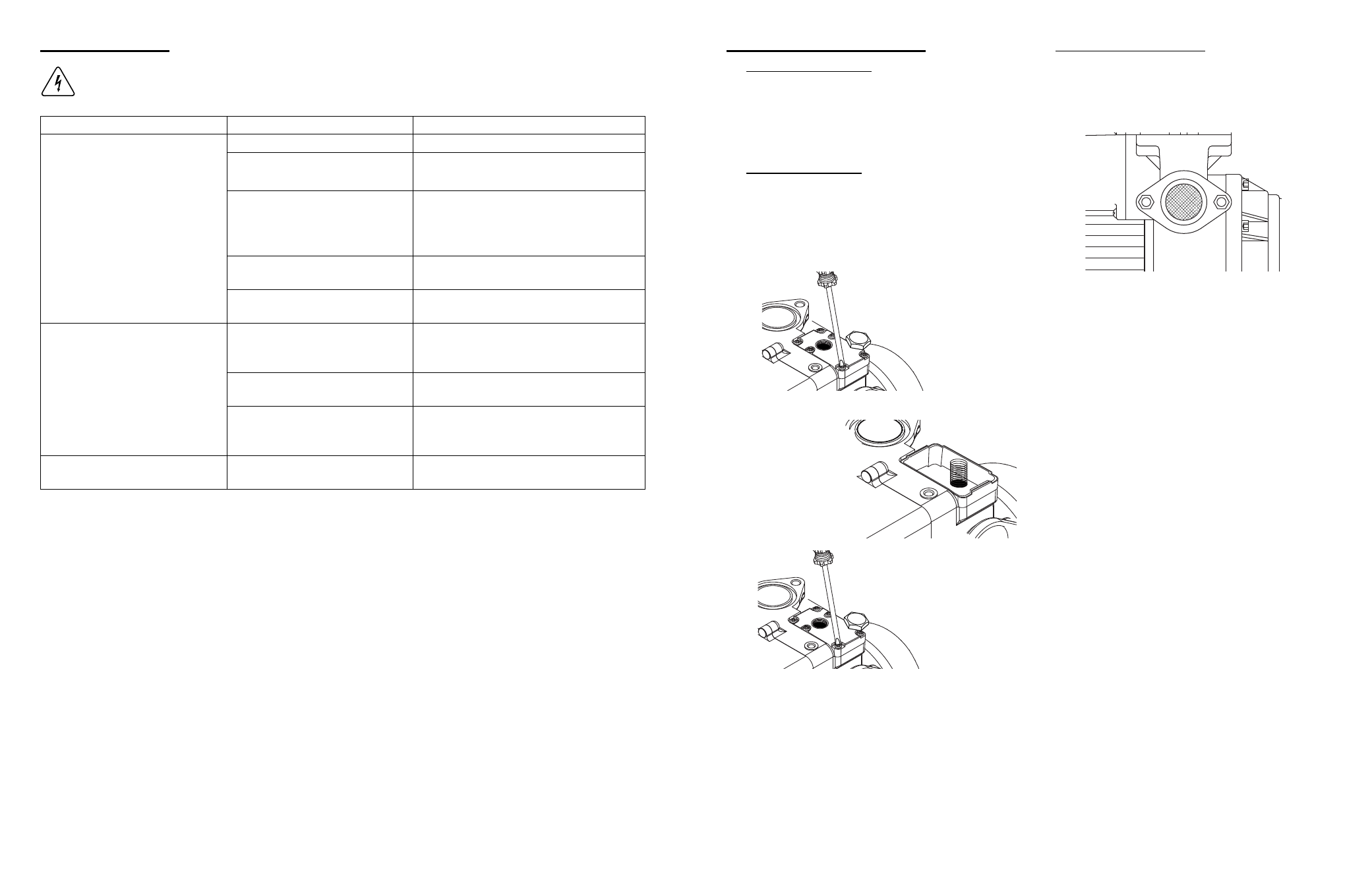

FIG 4 – INTERNAL CHECK vALvE

a. Remove the air relief

port and top cover

b. Confirm the spring

and check valve are

free of debris

a. Reassemble the top

cover and air relief

port

IL1308

• Pump Suction Inlet Screen – if internal debris

blocks or restricts the inlet suction screen (FIG

5), manually clean with hands.

FIG 5 – INLET SCREEN

IL1310