Star Water Systems 3SDHL User Manual

Page 3

3

© 2011. All rights reserved.

6. do not allow the cords to interfere with the float

control motion or to drape over the pump motor. With

electrician's tape, secure the cord to the discharge

pipe. This will provide protection for the cord and

make a neat installation.

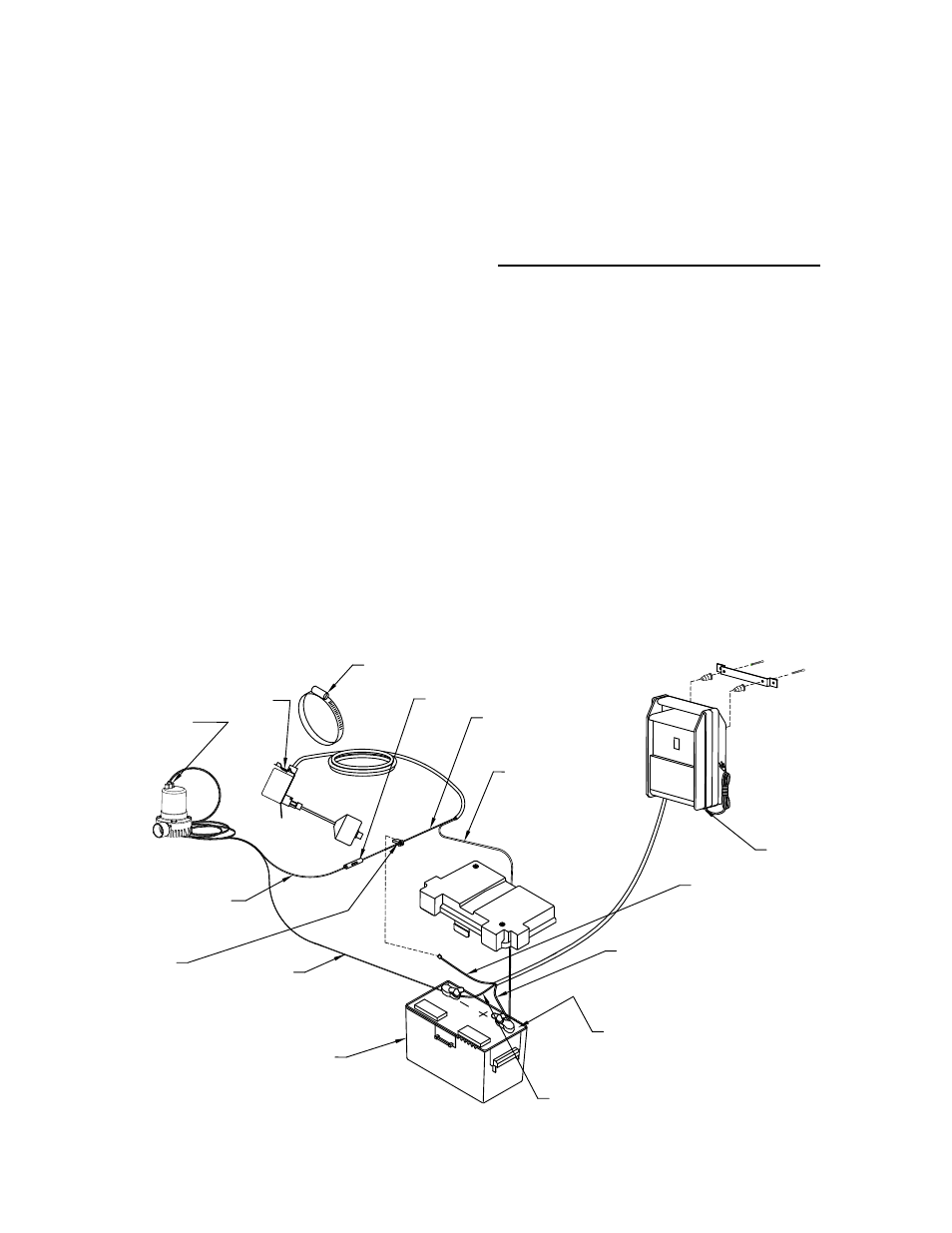

7. Install dC control charger (see Fig. 2) by using

the wall bracket and anchors provided. If more

convenient, the control charger may be set on a

nearby shelf or ledge. The control charger should be

located 3 or 4 ft. above the sump. To reduce noise

from vibration, it is recommended that the charger be

anchored with the wall bracket provided.

8. Connect the leads from the control charger to the

battery terminals. red pos. (+) lead to positive

terminal and black neg. (-) lead to negative battery

terminal. upon proper connection, test alarm will

sound. press alarm reset to silence. This indicates

proper charger to battery connection. Correct

battery hook up is essential for operation of the

system. use wing nuts supplied with battery and

eyelet connectors on battery wire leads. The positive

terminal is the larger stud, 3/8" diameter. The smaller

stud, 5/16" diameter is the negative terminal. Apply

grease to the terminals to help prevent corrosion.

9. Connect the black lead from the pump to the negative

(-) battery terminal. Connect the white or red lead

from the pump to the white lead from the switch. This

connection is made at the fuse installed on the switch

wire (see Fig. 2). Connect the black lead from the

switch to the positive (+) battery terminal.

10. Connect the blue sensor wire to the sensor connector

(Fig. 2).

11. Close battery box and secure cover. Carpeted or

wood barrier between the battery case and the floor

is recommended.

12. plug the control power cord into the 115V wall outlet.

The primary sump pump and the control box should

be on separate circuits.

13. plug in primary pump and restore electrical power at

the service entrance.

INITIAL START-UP AND OPERATION

1. Test the installation for leaks by running water into

the sump allowing for normal operation of the primary

pump.

2. Check the control charger. The “red” power on light

will be lit when the unit is plugged into the 115V

wall outlet. The “yellow/green” light will indicate the

condition of the battery.

3. disconnect primary pump before touching any

component in the sump pit.

4. Lift float switch. The dC backup pump will run and

the alarm will sound. Lower float switch immediately

after pump has started running. pump is running

dry during initial check out for several seconds.

CAuTION Continuous dry running may cause

overheating and damage the pump seals. upon

release of the float switch, the pump will shut off.

press the reset button to turn the alarm off.

5. Complete the final testing of your installation by

disconnecting the power to the primary pump and the

IL1008

Float Switch

DC Back-up

Pump

White or Red

Lead to Float

Splicer

Black Lead

to Negative

Battery Box

Clamp

15 Amp Fuse

White Lead

to DC Pump

Black Lead

to Positive

DC

Control Box

Blue Lead to Float Switch

Black with Red Tracer to Positive

12 Volt Marine Battery

Supplied by User

Black Lead to Negative

FIG. 5

FIGURE 2