Star Water Systems 3SDHL User Manual

Page 2

2

© 2011. All rights reserved.

11.

CAUTION: Check to be sure your power source

is capable of handling the voltage requirements of the

motor, as indicated on the pump name plate.

12.

CAUTION: The installation of automatic pumps

with variable level float switches or nonautomatic

pumps using auxiliary variable level float switches

is the responsibility of the installing party and care

should be taken that the tethered float switch will not

hang up on the pump apparatus or pit peculiarities

and is secured so that the pump will shut off. It is

recommended to use rigid piping and fittings and the

pit be 18" or larger in diameter.

13.

CAUTION: Information - vent hole purpose.

It is necessary that all submersible sump pumps

capable of handling various sizes of solid waste be of

the bottom intake design to reduce clogging and seal

failures. A check valve with an integral weep hole

is incorporated in the installation to purge the unit of

trapped air (See page 4). Trapped air is caused by

agitation and/or a dry basin. Vent hole should be

checked periodically for clogging. NOTe: THe HOLe

MuST Be CLeANed perIOdICALLY. Water stream

will be visible from this hole during pump run periods.

14.

CAUTION: pump should be checked frequently

for debris and/or build up which may interfere with the

float “on” or “off” position. repair and service should

be performed by Star Water Systems Authorized

Service Station only.

15.

CAUTION: Sump pumps are not designed for

use in pits handling raw sewage.

16.

CAUTION: Maximum operating temperature

for standard model pumps must not exceed 104°F

(40°C).

Note: pumps with the "cCSAus" mark are tested to uL

Standard uL778 & CSA Standard C22.2 No. 108.

GENERAL INFORMATION

The 2N1 system is designed to provide a primary and a

backup sump pumping capabilities. The primary pump

will operate as long as it is receiving AC electrical power.

The AC power is interrupted, the backup sump pump

will begin pumping automatically. The primary pump,

backup pump, electronic controls and all parts required

for installation are included except the battery which is

supplied by the user.

1. The primary pump is equipped with an

omnidirectional mechanical float switch. The pump

will turn on automatically when the water level

in the sump reaches approximately 10.25” and

automatically turn off when the water is pumped

down to 4.125”. The back-up pump is equipped

with a vertical float switch. The pump will turn on

automatically when the water level in the sump

reaches approximately 11” and automatically turn off

when the water is pumped down to 9.25”.

2. The sump pit must be a minimum of 22" deep and

18" in diameter. The pump assembly requires a

minimum diameter of 18" so that the float switches

will operate without restriction. Any smaller diameter

may restrict the switches operation, resulting in pump

failure.

INSTALLATION

1. For your safety, turn off the electrical power at the

service entrance to avoid any possible electrical

shock hazards.

2. On a replacement installation, remove the existing

pump from the sump by disconnecting the discharge

pipe or hose from the old pump. depending on how

your old pump is installed, unscrew clamps and

discard old corrugated hose, or unscrew galvanized

or plastic pipe from pump discharge. If discharge

pipe cannot be removed easily, saw through the pipe

about five feet above the pump discharge.

3. After removing the old pump, remove sediment,

debris, and any standing water from the sump pit.

4. place your pump assembly in the sump and attach

the discharge piping – The pipe must be supported

from above to ensure adequate support for the pump

assembly.

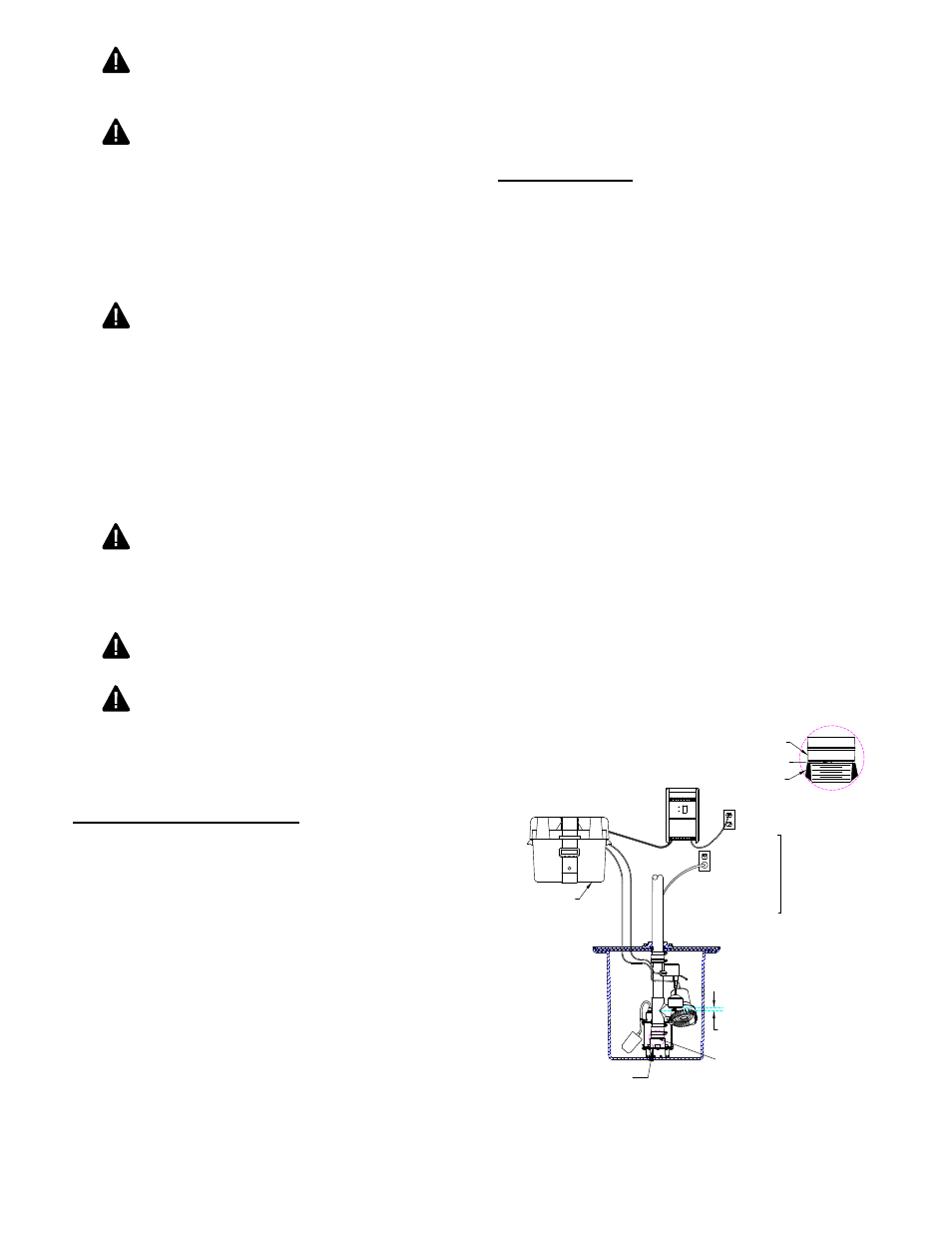

5. Be sure that the pump assembly is positioned so that

the float switches move freely without touching the

wall of the sump or other obstructions. (See Fig. 1)

ensure that the “off” level of the float is 1" min. above

the discharge tee of the dC backup pump (see Fig.

1). Move floats up and down, making sure of free

movement without interference from any obstructions

inside the sump or lid. Very shallow sumps may

require some adjustment to the vertical float to avoid

overfilling or backing up of water into the sump inlet.

IL1007

Battery Box

Check Valve

Weep Hole Provided

Pump

Discharge

Charger

Outlet

Primary

Pump Outlet

Detail “A”

Must be

installed

on two

separate

circuits

IMPORTANT: Off

level of float assembly

must be 1 in. minimum

above center of tee.

1 in. min.

See Detail “A”

FIGURE 1 - DC PUMP PLUMBED IN LINE WITH

SUBMERSIBLE PUMP