Star Water Systems 473707 User Manual

Page 4

6

7

Face Plate

Screws (4)

Face Plate

Gasket

Pump Cavity

Impeller

Spring

Brush

Cap

Brush

Cap

Spring

Brush

Cap

Water Source

Outlet

Inlet

3 ft. Max.

Vertical

INSTALLATION INSTRUCTIONS

TROUBLESHOOTING

7

7. If pump does not start to pump water within 30 seconds,

unplug and re-check the installation and plumbing as

follows.

- Check to be sure pump is located so that the water

source is within reach of supplied 6 ft. inlet hose.

- Check to be sure all inlet connections are air and water-

tight and inlet hose is as short as possible.

- Check to be sure inlet hose is below the surface of the

water source.

- Check to be sure the outlet hose is less than 25 ft. in

length and is above the surface of the outlet water.

CARE AND MAINTENANCE

1. Always drain pump when not in use. If pump is going to be

out of use for a month or longer, flush with fresh water and

remove face plate cover. Remove impeller, clean inside

pump cavity and apply a generous coating of petroleum jelly

(not included) to the inside of the cavity and the impeller

before replacing the impeller. The pump should be checked

frequently for proper operation. If anything has changed

since the pump was new, it should be repaired or replaced.

CAUTION: Only qualified electricians should repair this unit.

Improper repair and/or assembly can cause electrical shock

hazard.

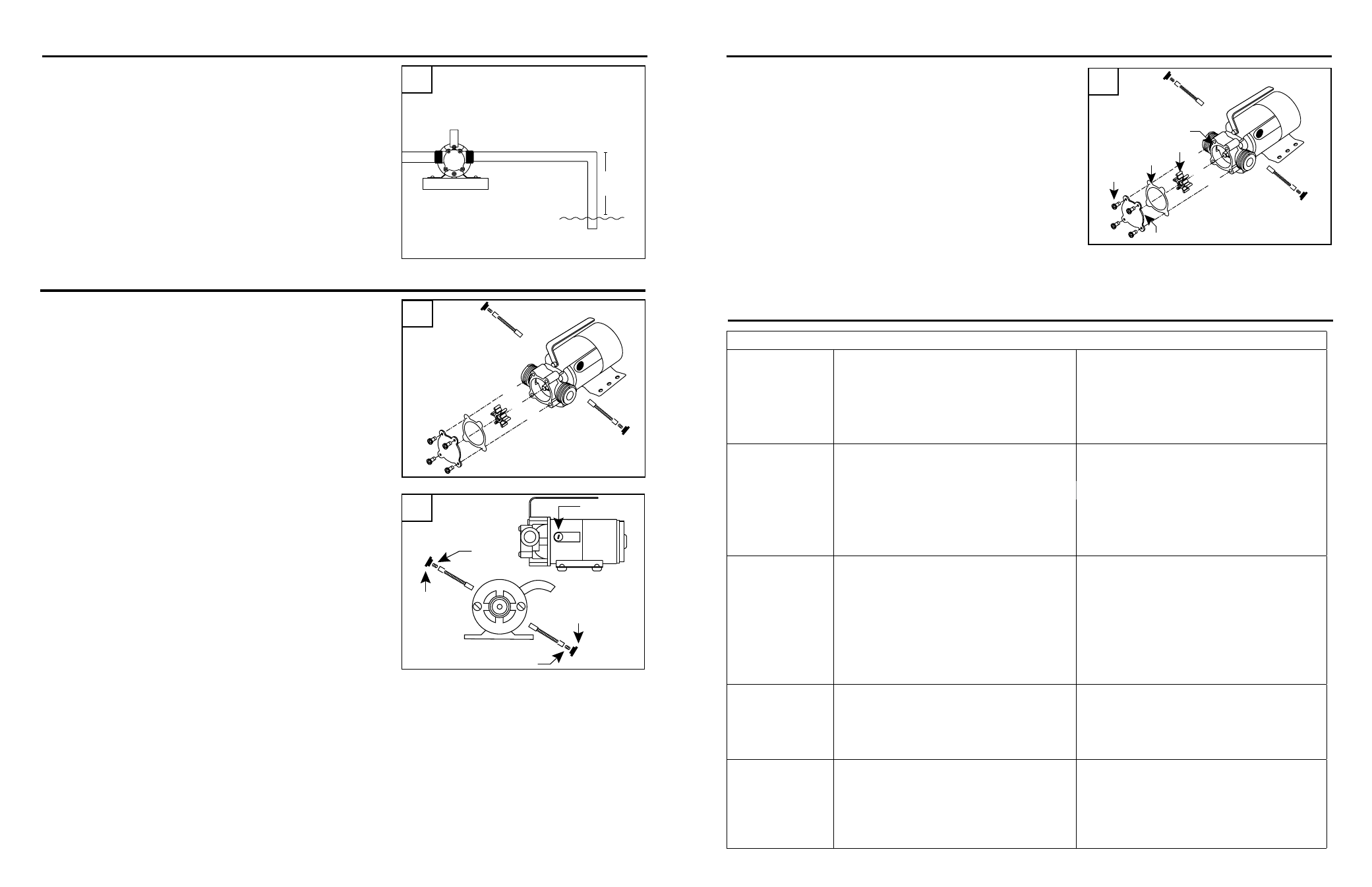

2. How to Replace Brushes (115V pump only)

NOTE: Motor brushes (not included) are normal wear items and

must be replaced periodically.

- Be sure pump is disconnected from power source.

- Unscrew brush cap located along the side of the motor.

Remove brush and spring and spring cover by pulling them

straight out of the brush holder.

- Install new brush and spring assembly (not included), keeping

the new brush curvature aligned the same as the previous

brush.

- Replace cap.

3. How to Replace Impeller

NOTE: Replace the impeller when it has been worn or

damaged by foreign objects, improper liquid or running dry.

- Remove four face plate screws, face plate and gasket.

- Remove damaged or worn impeller.

- Clean the inside of the pump cavity and remove any foreign

materials that might prevent the impeller from moving easily.

- Apply petroleum jelly to the inside of the pump cavity and the

outside of the new impeller (not included).

- Align the flat on the new impeller with the flat on the motor

shaft. Push into place while twisting blades in a clockwise

direction.

- Place new gasket on pump cavity face, align holes and

replace cover. Tighten all four screws evenly and snugly.

1

2

3

Problem

Possible Cause

Corrective Action

Pump will not

prime or retain

prime after

operating.

1. Pump won’t prime.

1. See priming instructions on page 6.

2. Suction lift too high.

2. Move pump closer to water source.

3. Hose kinked.

3. Straighten hose.

4. Hose fitting not tight on inlet.

4. Tighten fitting.

5. Air leak in suction hose.

5. Repair or replace hose.

Pump runs

but no water is

discharged.

1. Hose kinked.

1. Straighten hose.

2. Pump is not primed.

2. See priming instructions on page 6.

3. Defective impeller.

3. Replace impeller.

4. Suction lift too high.

4. Move pump closer to water source.

5. Discharge height too great.

5. Reduce discharge height.

6. Clogged inlet.

6. Clean inlet.

Motor runs too

hot.

1. Voltage incorrect.

1. Connect to 115 volt outlet.

2. Restricted discharge hose.

2. Increase hose diameter to 3/4 in.

3. Impeller damaged.

3. Replace impeller.

4. Liquid too viscous.

4. Reduce viscosity of liquid.

5. Plugged or kinked discharge.

5. Clean and straighten hose.

6. Insufficient air flow on motor.

6. Make sure ample fresh air is available

at the motor.

Flow rate is low. 1. Hose kinked.

1. Straighten hose.

2. Clogged impeller.

2. Clear obstruction.

3. Worn impeller.

3. Replace impeller.

4. Excessive length of hose.

4. Reduce length of inlet and outlet hose.

Pump will not

run.

1. No power.

1. Verify that unit is plugged into 115 volt

outlet.

2. Impeller jammed.

2. Clean pump cavity and impeller.

3. Motor overheated.

3. Motor has automatic thermal protector.

Wait fifteen minutes for motor to cool.

CARE AND MAINTENANCE