1 temperature errors cause by non-graybodies – LumaSense Technologies ISR 320 User Manual

Page 18

ISR 320 Manual

Settings / parameter descriptions 18

Note: Emissivity Slope K Settings: 0.800 to 1.250 in steps of 1/1000 (2-color mode).

4.2.1 Temperature Errors Cause by Non-Graybodies

A graybody target has emissivity that is the same at each of the two wavelengths used for

measurements and is constant throughout the temperature range. The ratio of the emissivities,

1 / 2= 1 and stays constant regardless of the target temperature. When a target deviates from

this, that is when 1 / 2 does not equal 1.0 and a slope adjustment is required. For many

materials, this is a one-time adjustment.

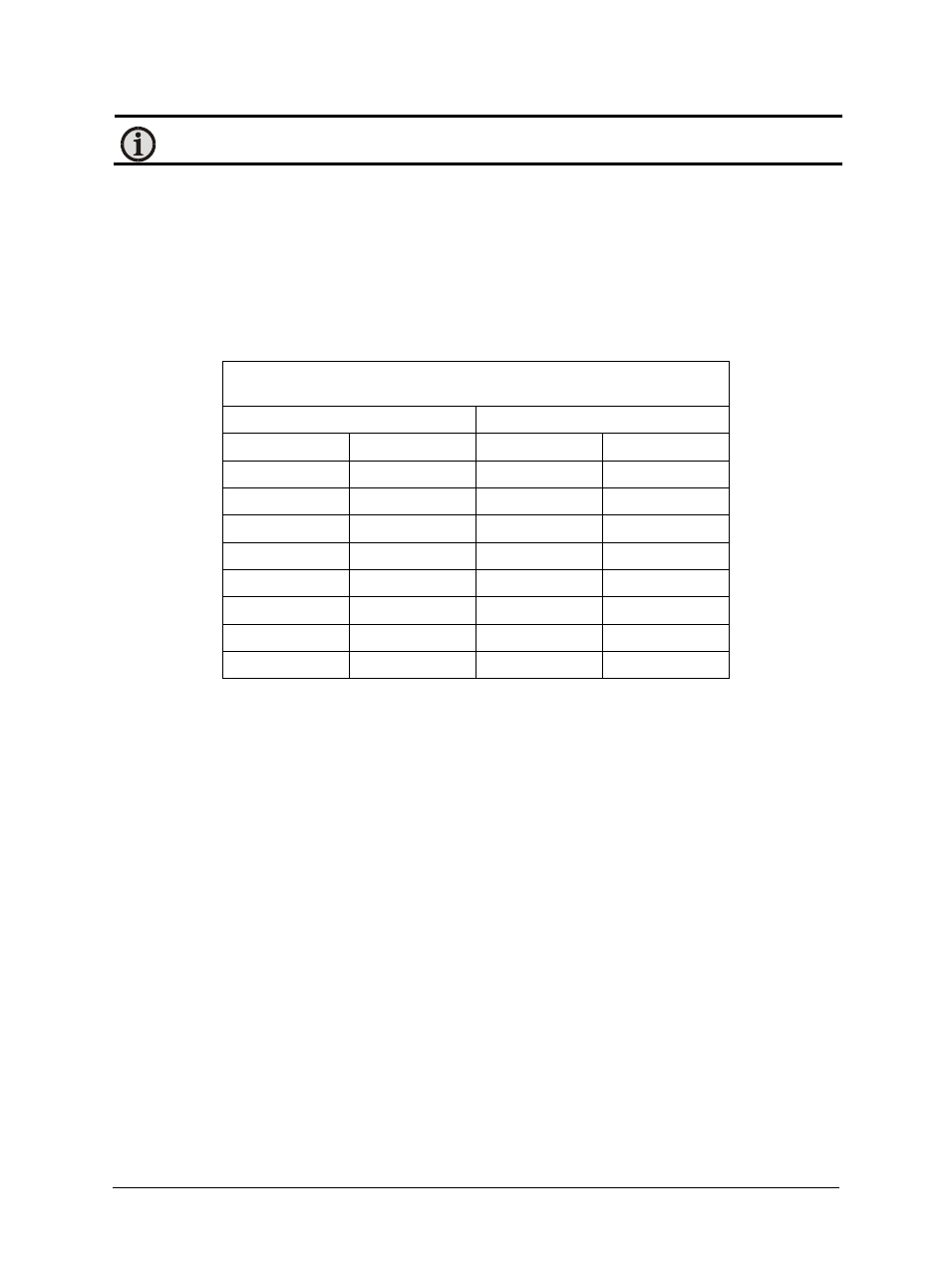

The following table illustrates the ISR 320 reading errors that can occur when the slope setting

differs from the actual material emissivity ratio.

TABLE OF EXPECTED ERROR WHEN EMISSIVITY OF ONE

WAVELENGTH IS 1% DIFFERENT FROM THE SECOND WAVELENGTH

TEMPERATURE

ERROR DEG.

°F

°C

°F

°C

1300

700

18

10

1500

815

20

11

1700

926

22

12

1900

1040

25

14

2100

1150

25

14

2300

1260

27

15

2500

1370

29

16

3000

1650

36

20

The table shows typical errors that can result when the emissivity of one wavelength differs

from the other wavelength by only 1%. The errors can get quite large as temperatures increase.

This error can be much larger than a 1-color IR pyrometer would produce for 1% emissivity

change. Therefore, it is important to select the proper mode (2-color vs. 1-color) on the ISR 320

to measure a specific material.

Another source of error is dust or smoke in the optical path which alters the transmission in one

wavelength more than the other. If the “dust” transmits 1% less energy at wavelength 1 than at

wavelength 2, the error table above also applies. Since not all smoke, dust, or dense steam

transmits equally at each wavelength, errors may become larger than expected for a 2-color

instrument. Usually the smoke and dust are the result of the material being processed and can

be cleared from the sight path by a fan or air purge tube.

In some materials, the emissivity may change at different rates with material temperature. Some

materials exhibit great changes in emissivity with temperature or time as oxidation modifies the

surface finish of the material. Such materials are not suited for measurement with 2-color

instruments. When problems are compounded with spectrally absorbing dust or smoke

(described above), obtaining reliable temperature readings with any 2-color instrument may be

impossible. In cases like this, a single color instrument using the shortest wavelength possible

would be the better choice. If this problem is encountered, switch the ISR 320 to 1-color mode.

In some situations, the single color mode will outperform the ratio mode.