Operation, Welder operation – Lincoln Electric IM707 Commander 500 User Manual

Page 24

B-7

OPERATION

B-7

BREAK-IN PERIOD

The engine used to supply power for your welder is a

heavy duty, industrial engine. It is designed and built for

rugged use. It is very normal for any engine to use

small quantities of oil until the break-in is accom-

plished. Check the oil level twice a day during the

break-in period (about 200 running hours).

IMPORTANT

IN ORDER TO ACCOMPLISH THIS BREAK-IN, THE

UNIT SHOULD BE SUBJECTED TO HEAVY LOADS,

WITHIN THE RATING OF THE MACHINE. AVOID

LONG IDLE RUNNING PERIODS.

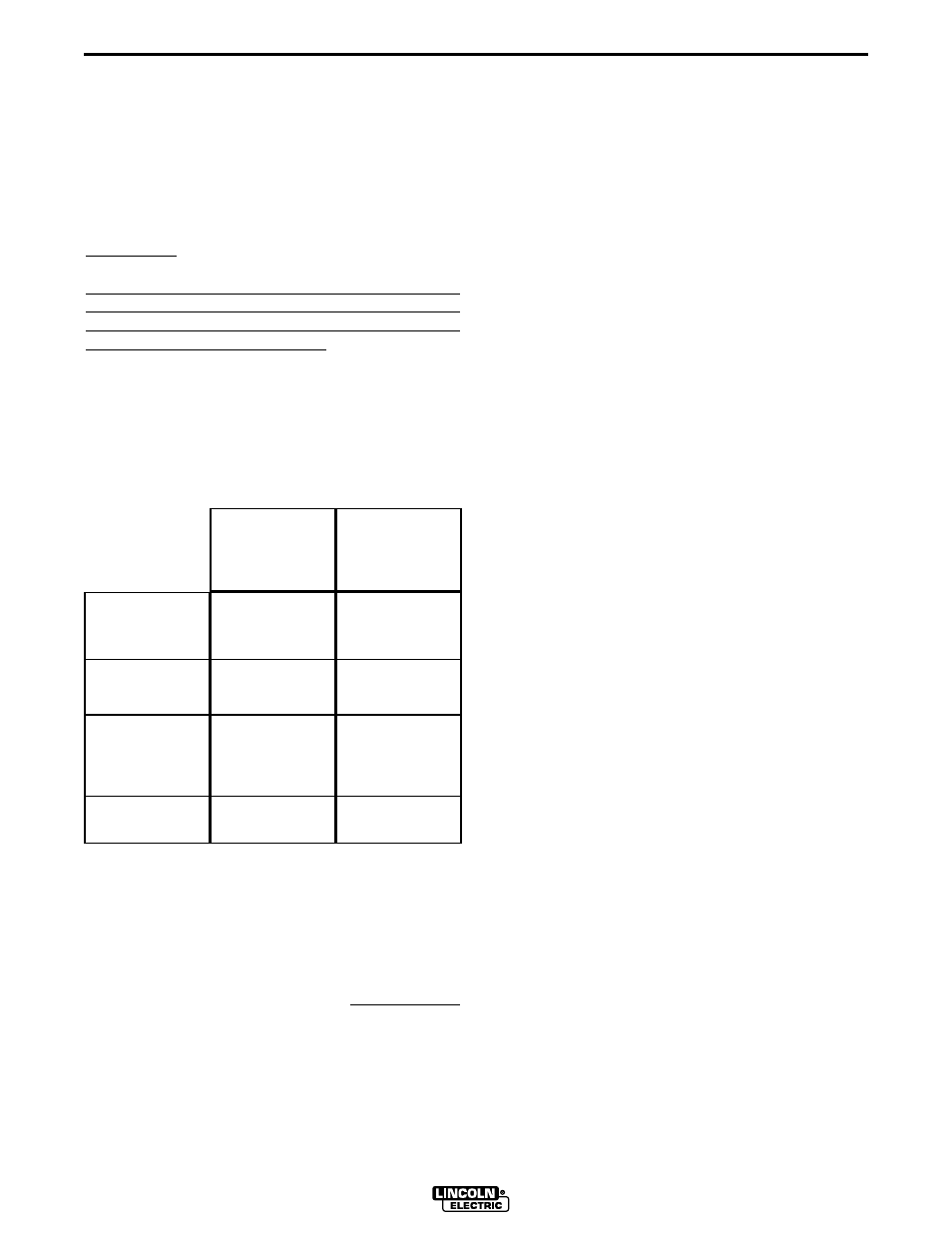

TYPICAL FUEL CONSUMPTION

Refer to Table B.2 for typical fuel consumption of the

COMMANDER 500 CUMMINS’s Engine for various

operating scenarios.

Table B.2

Cummins B3.3 Engine Fuel Consumption

WELDER OPERATION

STICK WELDING

The COMMANDER 500 CUMMINS can be used with a

broad range of DC stick electrodes.

The “WELD MODE” switch provides five overlapping

slope controlled current ranges. The OUTPUT adjusts

the current from minimum to maximum within each

range. Voltage is also controlled by the OUTPUT in the

slope controlled setting. These slope controlled set-

tings are intended for “out-of-position” welding, includ-

ing pipe welding, where the operator would like to con-

trol the current level by changing the arc length.

PIPE WELDING

The COMMANDER 500 CUMMINS is equipped with

special circuitry to minimize pop-outs in the five slope

modes at any open circuit voltage.

For a soft arc characteristic, set the "WELD MODE"

Switch to the lowest setting that still provides the cur-

rent you need and set the "OUTPUT" near maximum.

For example: to obtain 140 amps and a soft arc, set the

" WELD MODE" Switch to the "150 MAX" position and

then adjust the "OUTPUT" for 140 amps.

When a forceful "digging" arc is required, use a higher

setting and lower the open circuit voltage. For example:

to obtain 140 amps and a forceful arc, set the “ WELD

MODE” to the "250 MAX" position and then adjust the

"OUTPUT" to get 140 amps.

CONSTANT CURRENT (CC) WELDING

The CC - STICK position of “30 to 575", the "WELD

MODE" Switch is designed for horizontal welds with all

types of electrodes especially low hydrogen. The

"OUTPUT" adjusts the full range of 30 to 575 amps.

This setting provides a soft, constant current arc. If a

more forceful arc is desired, then select the proper

range from the slope controlled current ranges.

In the CC mode, sticking can be prevented by adjust-

ing the “ARC CONTROL”. Turning this control clock-

wise, increases the short circuit current, thus prevent-

ing sticking. This is another way of increasing arc force.

TIG WELDING

The most clockwise position of the WELD MODE

switch is for TIG welding in the range of 20 amps to 250

amps, with a “Touch Start” feature. To initiate a weld,

the OUTPUT is first set to the desired current and the

tungsten is touched to the work. During the time the

tungsten is touching the work there is very little voltage

or current and, in general, no tungsten contamination.

Then, the tungsten is gently lifted off the work in a rock-

ing motion, which establishes the arc.

The COMMANDER 500 CUMMINS can be used in a

wide variety of DC Tungsten Inert Gas (TIG) welding

applications. In general the “Touch Start” feature allows

contamination free starting without the use of a Hi-Freq

unit. But the K930-1 or -2 TIG module or K799 Hi-Freq

unit, can be used with the COMMANDER 500 CUM-

MINS. The settings for these follow the tungsten cur-

rent range table.

COMMANDER 500 CUMMINS

Low Idle - No

Load 1475 RPM

High Idle - No

Load 1900 RPM

DC CC Weld

Output 500

Amps @ 40 Volts

Auxiliary Power

12,000 VA

.45 gallons/hour

(1.70 liters/hour)

.81 gallons/hour

( 3.07 liters/hour)

1.88 gallons/hour

( 7.12 liters/hour)

1.23 gallons/hour

(4.66 liters/hour)

55.6

30.9

13.3

20.3

Cummins B3.3

56 Hp

@1800 RPM

Running Time for

25 gallons

(Hours)