Hired-Hand Super-Savers (Forced Air Heaters) XL: SS-225-XL User Manual

Page 3

4801-5101

Rev

6-09

Page

3

of

26

Super Saver XL CE Heater

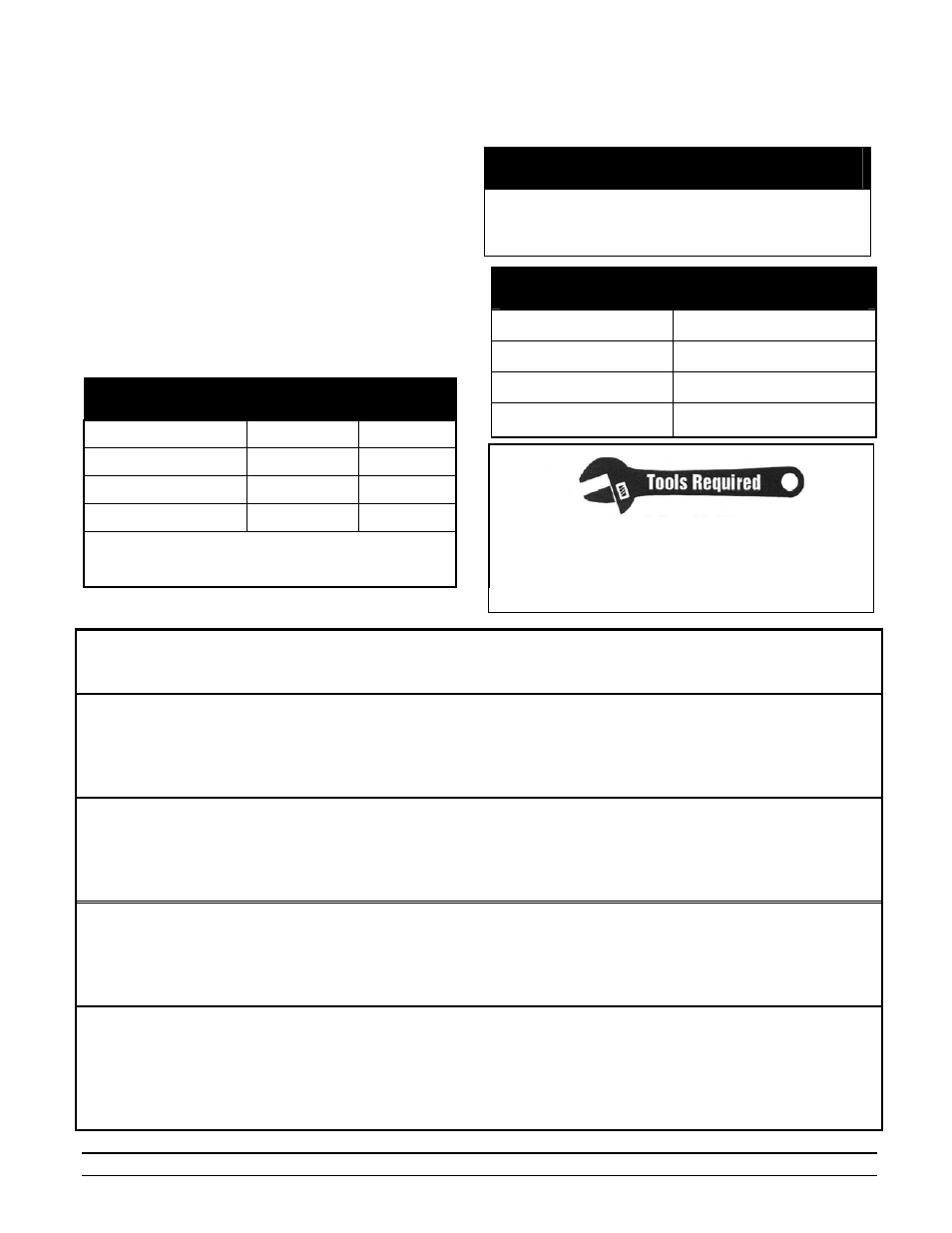

Adjustable

Wrench

Gas Leak Testing

Pipe Glue

¼ in. (7 mm.) Nut Driver

Install screw hooks with hammer or drill.

BE SURE TO CHECK DELIVERY!

Locate packing slip and make sure all of the listed

parts are enclosed. If not, call your Hired-Hand

Distributor immediately.

Table Of Contents

1.

Specifications And Requirements..................3

2.

Warnings And Cautions .................................4

3.

Maintenance And Warranty ...........................5

4.

Installation......................................................6

5.

User Instructions ............................................8

6.

Gas/Air Requirements .................................10

7.

Conversion To Other Gases ........................10

8.

Component And Wiring Diagram .................13

9.

Ladder Type Schematic Diagram ................14

10.

Servicing Instructions...................................15

11.

Pipe Sizing For Sufficient Gas Service........20

12.

Parts & Assemblies......................................22

1. Specifications And Requirements

Model No.

Maximum Input

Ventilation

SS-225-XL

65.9 kW (225,000 BTUH)

1700 m

3

/h (1000 CFM)

Butane & Propane

Gas:

Maximum 57.5 mbar (22.7 in. w.c.) and minimum 25 mbar (9.9 in. w.c.) inlet gas

supply pressure acceptable at heater input. Burner manifold pressure 25 mbar (10

in. w.c.) at maximum input. Gas pressure should be checked by certified gas

technician while heater is in operation. All sealing devices must be restored after the

gas conversion. Refer to Section 6. Gas/Air requirements.

Natural Gas:

Maximum 25 mbar (9.9 in. w.c.) and minimum 17 mbar (6.7 in. w.c.) inlet gas

pressure acceptable at heater input. Burner manifold pressure 9.45 mbar (3.8 in.

w.c.) at maximum input. Gas pressure should be checked by a certified gas

technician while heater is in operation. All sealing devices must be restored after the

gas conversion. Refer to Section 6. Gas/Air requirements.

LHV Natural Gas

Maximum 30 mbar (11.9 in. w.c.) and minimum 20 mbar (7.9 in. w.c.) inlet gas

supply pressure acceptable at heater input. Burner manifold pressure 14.1 mbar

(5.6 in. w.c.) at maximum input. Gas pressure should be checked by a certified gas

technician while heater is in operation. All sealing devices must be restored after the

gas conversion. Refer to Section 6. Gas/Air requirements.

Refer to heater ratings plate for unit voltage, amperage, and frequency ratings.

READ ALL INSTRUCTIONS BEFORE YOU START ASSEMBLING

HEATER DIMENSIONS

WEIGHT

60 kG (130 lb.)

HEIGHT

76.2 cm (30 in.)

WIDTH

62.2 cm (24½ in.)

DEPTH

48.9 cm (19¼ in.)

MINIMUM CLEARANCES

Measured From

Inches

mm

Ceiling 12

305

Wall 12

305

Floor 20

500

Livestock must not be allowed to contact

heater or come within 3 meters (10 feet)

of hot air discharge