Important, Nominal internal, Iron pipe size diameter – Hired-Hand Super-Savers (Forced Air Heaters) XL: SS-225-XL User Manual

Page 21: Ips) length of pipe, meters, Iron pipe diameter, Size (ips) length of pipe, meters

4801-5101

Rev

6-09

Page

21

of

26

Super Saver XL CE Heater

IMPORTANT !

Tables 3 and 4 are based on values given in the Gas Engineers Handbook and are intended as a guide only.

Consult your gas supplier for gas capacity and pipe size information for your particular piping system.

4. In the appropriate table, NG (Table 3) or LP

(Table 4), select the column showing the ELOP

or the next longer length if the table does not

give the exact length. Use this column to

compare table values to the HVR values. In this

example, the Natural Gas (NG) table is selected.

From step 3, ELOP = 60 m. Locate the column

labeled 60 m in Table 3.

5. Select a pipe section and read down the ELOP

column to find the maximum gas capacity that

matches the HVR for that pipe section. If the

exact figure is not shown, choose the next larger

figure in the column. In this example, start with

pipe section c-e. For pipe section c-e, HVR = 12

kW. Since 12 kW is not listed, read the next

higher value from the table. The next higher

value is 21.

6. Follow the row leftward until you reach the

column labeled ‘Nominal Iron Pipe Size’, or

‘Internal Diameter’, and read the number of the

pipe size for the particular pipe section.

Example: For pipe section c-e, the iron pipe size

is 19.1 mm (3/4 in.) (Table 3: Locate 21 in the 60

m column, read left).

7. Repeat steps 5-6 for each pipe section in the

system. Use 60 m column for all readings.

Example: The table ‘Pipe Sizes Determined For

Arbitrary Piping System’, summarizes the pipe

sizes determined in this example.

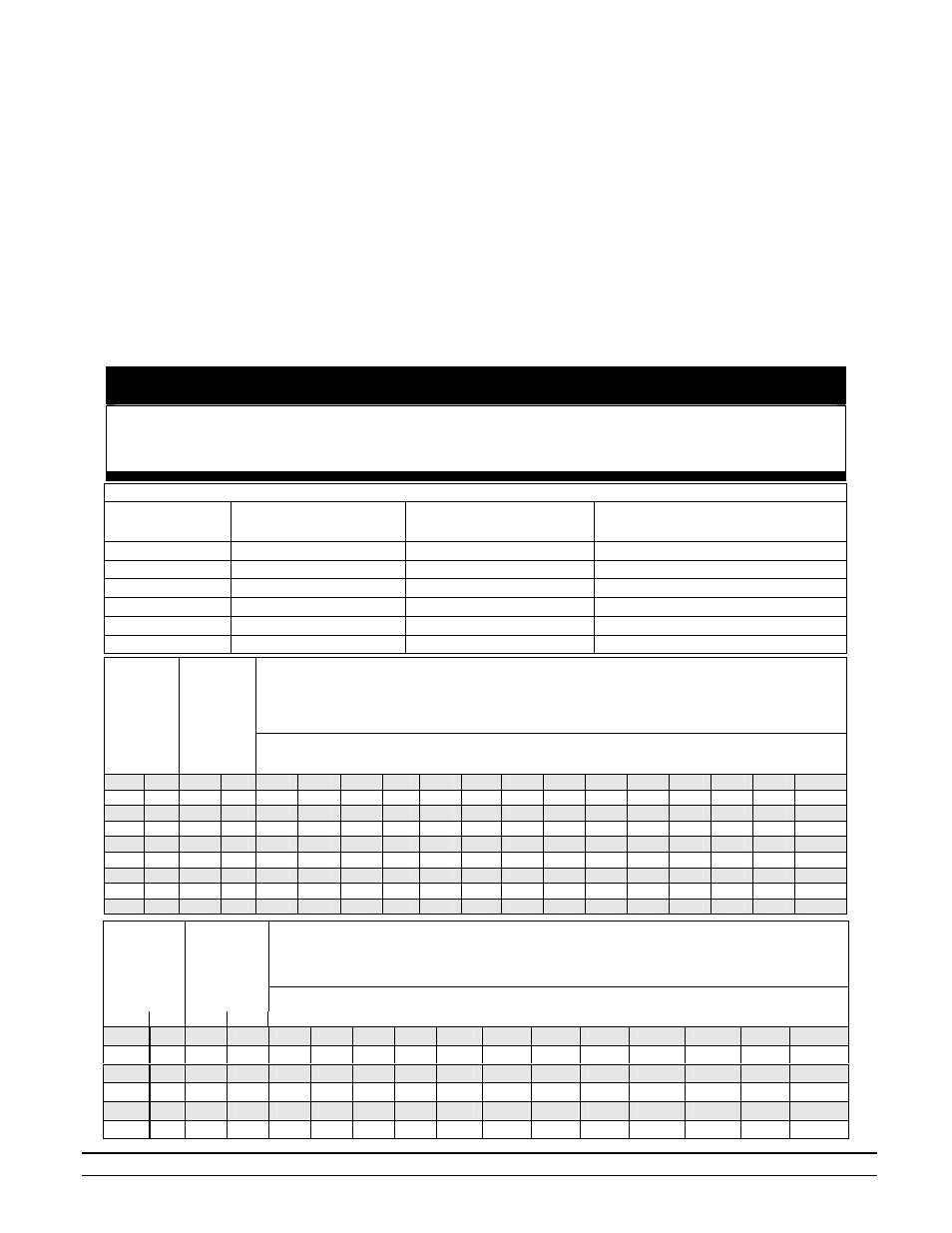

Table 3. Maximum Capacity Of Pipe In kWh (kilowatt hour)

Nominal Internal

Natural Gas (Methane) @ Pressure Drop Of 0.20 mbar (0.08 in. w.c.)

Iron Pipe

Size

Diameter

Values listed are for 0.6 sp.gr. based on Heat Of Combustion of 10.2 kWh/m

3

(IPS)

Length Of Pipe, meters

m

in.

mm

in.

3

6

9

12

15

18

21

24

27

31

46

60

75

90

12.7

.5

15.8

.622

51

35

28

24

22

19

18

17

15

14

12

10

8

7

19.1

.75

20.9

.824

106 73 59 50 44 40 37 35 32 30 25 21 17 16

25.4

1

26.7

1.05

199

138

110

94

84

76

70

65

60

57

47

40

32

29

31.8

1.25

35.1

1.38

410 278 226 193 170 155 144 135 126 117 95 82 64

60

38.1

1.5

40.9

1.61

615

427

346

290

264

237

220

202

190

182

146

126

95

90

50.8 2 52.6

2.07

1158 806 645 556 492 445 410 380 357 337 278 234 180 175

63.5

2.5

62.7

2.47

1846

1275

1032

879

776

703

659

600

571

542

439

375

283

278

76.2 3 78.0 3.07 3223 2256 1831 1554 1392 1260 1143 1084 1011 952 776 668 544

492

102

4

102

4.03

6741

4630

3751

3195

2843

2579

2374

3198

2110

1964

1611

1348

1109

1005

Table 4. Maximum Capacity Of Pipe In kWh (kilowatt hour)

Nominal Internal

Liquid Propane (LP) @ Pressure Drop Of 0.20 mbar (0.08 in. w.c.)

Iron Pipe

Diameter

Values listed are for 1.6 sp.gr. based on Heat Of Combustion of 25.8 kWh/m

3

Size (IPS)

Length Of Pipe, meters

mm

in.

mm

in.

3

6

9

12

15

18

21

24

27

31

38

46

12.7

.5

15.8

0.622

275

189

152

129

114

103

96

89

83

78

69

63

19.1 .75 20.9

0.824 567 393 315 267 237 217 196 185

173

162

146

132

25.4

1

26.6

1.049

1071

732

590

504

448

109

378

346

322

307

275

252

31.8 1.25 35.0 1.380 2205 1496 1212 1039 913

834

771

724

677

630

567

511

38.1

1.5

40.9

1.610

3307

2299

1858

1559

1417

1275

1181

1086

1023

976

866

787

50.8 2 52.5 2.067 6221 4331 3465 2992 2646 2394 2205 2047

1921

1811

1606

1496

Pipe Sizes Determined For Arbitrary Piping System

Pipe Section

HVR Value

(from step 2)

Closest value from Table

3

Pipe Size Determined

From Table 3

a-b

48

82

31.8 mm (1-1/4 in.)

b-c

24

40

25.4 mm (1 in.)

b-d

12

21

19.1 mm (3/4 in.)

b-f

12

21

19.1 mm (3/4 in.)

c-e

12

21

19.1 mm (3/4 in.)

c-g

12

21

19.1 mm (3/4 in.)