STI UNIVERSAL STOPPER SERIES User Manual

Page 4

2. If drilling into wood, four #6 x 1 ¼” screws (provided) should be used without anchors and the

mounting holes should be drilled 7/64” diameter to a depth of 1 ¼”. If drilling into masonry or

drywall (sheet rock), the wall anchors (provided) should be used and the mounting holes drilled 3/16”

diameter to a depth of 1 ¼”.

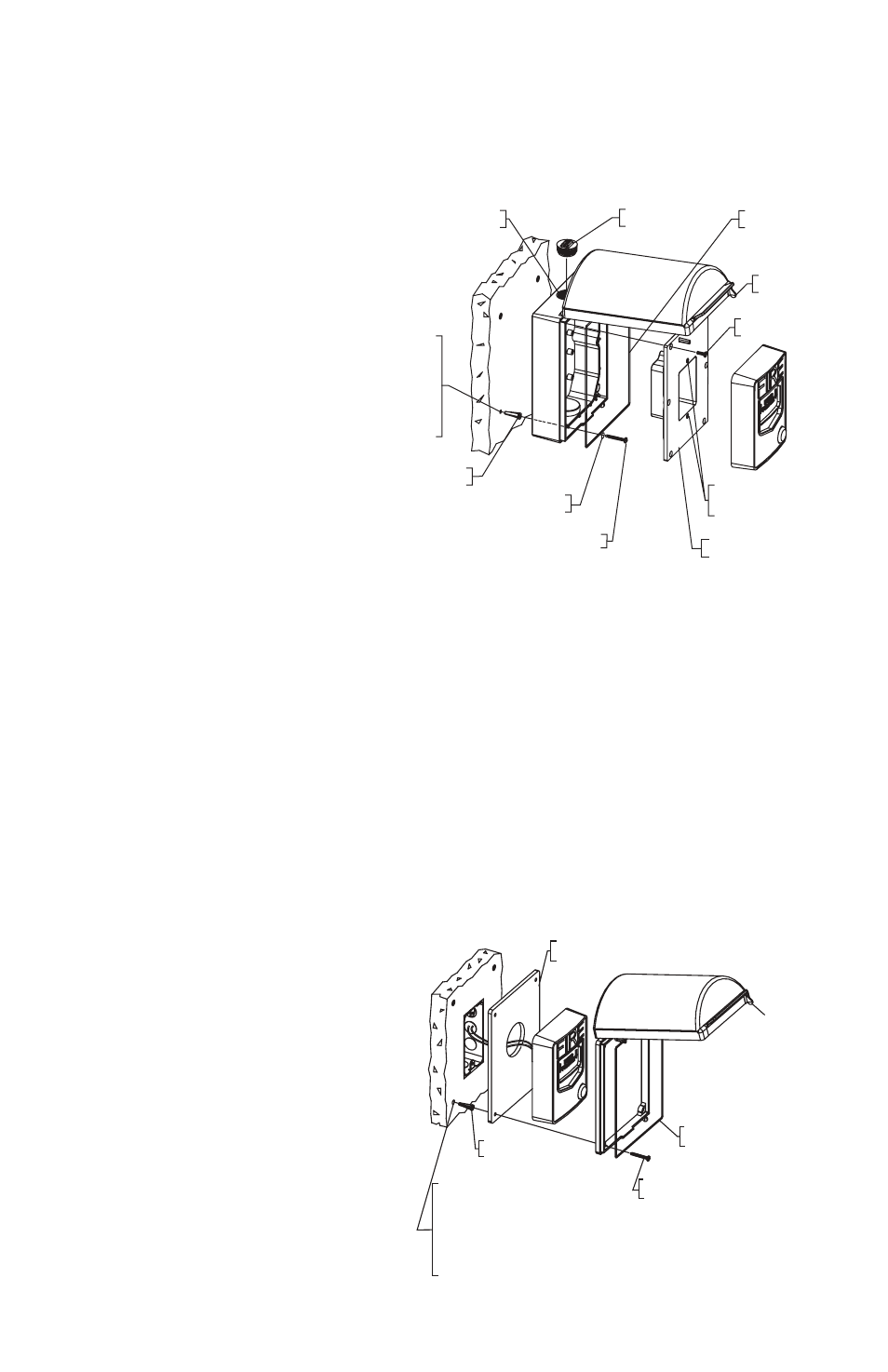

3. Refer to Fig. 2, 3 and 4 for illustrations of the different mounting configurations (BACKBOX,

FLUSH, SURFACE). For additional seal reliability, a silicone sealant may be applied between

optional backplate and wall.

4.

(For the BACKBOX

mounting option only)

If routing conduit from

above, run the conduit

through the hole in the

top of the housing.

5. (For the BACKBOX

mounting option only) If

routing from below, use

a flat head screwdriver

or coin to remove the

NPT Plug. Then knock

out a hole in the bottom

and run the conduit

up through the bottom

of the housing. Apply

thread sealant. Screw

the NPT plug back into

the threaded top of the

housing.

6. (For the SURFACE mounting option only) Note that the inserts fit flush to the housing only in one

orientation (see Fig. 4). Prior to applying either of the Conduit Weather Gaskets, ensure proper

orientation and fit of the desired inserts from the top or the bottom of the housing.

7. (For the SURFACE mounting option only) After noting the proper insert orientation, fit the appropriate

Conduit Weather Gasket size (1/2” or 3/4”) to the conduit. Then fit the gasket to the Conduit Insert or

directly to the housing knock-out. Repeat this step with the appropriate installation on the opposite.

For additional seal reliability, a bead of silicone may be applied to the conduit fitting.

8. (For the SURFACE mounting option only) Use the 3” gaskets (provided) to complete the seal across

the top and bottom insert locations. Overlap 1/8” of the existing Mounting Gasket on the Universal

Stopper body, run the cord into the preformed channel until it overlaps 1/8” of the opposing Mounting

Gasket.

The 3” gasket may need to be trimmed for a proper fit and seal.

9. Align mounting holes in frame to the screw holes made in the wall. If applicable, ensure a proper

seal is made between the wall and

the Mounting Gasket embedded on

the Universal Stopper. If needed, use

optional STI Backplate (STI-1314).

10. (For the BACKBOX mounting option

only) Insert the #6 x 1 ¼” Phillips Pan

Head Screws (provided) into the #6

O-rings STI-01317 (provided) to seal the

Backbox mounting holes.

11. Put the #6 x 1 ¼” Phillips Pan Head

Screws (provided) through the frame

holes into the drilled screw holes and

tighten to mounting surface.

Fig. 2 - BACKBOX MOUNTING OPTION

#6 x 1-1/4 SCREW

(4) PROVIDED

#6 ANCHOR

(4) PROVIDED

3/4 NPT FOR 3/4 CONDUIT

TOP AND BOTTOM

3/4 NPT PLUG

(1) PROVIDED

#6-32 x 1/2 in.

(6) PROVIDED

DRILL 3/16 DIA. HOLES

1-1/4 in. DEEP (4) PLACES

IF ANCHORS ARE USED

DRILL 7/64 DIA. HOLES

1-1/4 in. DEEP (4) PLACES

IF ANCHORS ARE NOT USED

COVER GASKET

(1) PROVIDED

#6-32 x 1/2 in.

(6) PROVIDED

#6 x 1-1/4 in. SCREW

(4) PROVIDED

#6 ANCHOR

(4) PROVIDED

3/4 NPT FOR 3/4 in. CONDUIT

TOP AND BOTTOM

3/4 NPT PLUG

(1) PROVIDED

#6 - 32 x 1/2 in. DEEP

THREADED FOR

MOUNTING DEVICES

DRILL 3/16 DIA. HOLES

1-1/4 in. DEEP (4) PLACES

IF ANCHORS ARE USED

DRILL 7/64 DIA. HOLES

1-1/4 in. DEEP (4) PLACES

IF ANCHORS ARE NOT USED

#6-32 x 1/2 in.

(6) PROVIDED

LOCKING

TAB

O-RING GASKET

(4) PROVIDED

LOCKING TAB

DEVICE MOUNTING PLATE

(1) PROVIDED

O-RING GASKET

(4) PROVIDED

COVER GASKET

(1) PROVIDED

DEVICE MOUNTING PLATE

(1) PROVIDED

#6 - 32 x 1/2 in. DEEP

THREADED FOR

MOUNTING DEVICES

COVER GASKET

(1) PROVIDED

#6 x 1-1/4 in. SCREW

(4) PROVIDED

#6 ANCHOR

(4) PROVIDED

DRILL 3/16 DIA. HOLES

1-1/4 in. DEEP WHEN USING ANCHORS

DRILL 7/64 DIA. HOLES 1-1/4 in. DEEP

WHEN ANCHORS ARE NOT USED

OPTIONAL BACKPLATE RECOMMENDED

WHEN MOUNTING TO UNLEVEL SURFACE

COVER GASKET

(1) PROVIDED

#6 x 1-1/4 in. SCREW

(4) PROVIDED

#6 ANCHOR

(4) PROVIDED

DRILL 3/16 DIA. HOLES

1-1/4 in. DEEP WHEN

USING ANCHORS

DRILL 7/64 DIA. HOLES

1-1/4 in. DEEP WHEN ANCHORS

ARE NOT USED

LOCKING TAB

LOCKING TAB

OPTIONAL BACKPLATE RECOMMENDED

WHEN MOUNTING TO UNLEVEL SURFACE

Fig. 3 - FLUSH MOUNTING OPTION

- 4 -