Stuart Turner TFL Automatic Flow Switch User Manual

Page 8

- 8 -

Cont ...

Where secondary circuits are in use, the pump should be sited as close as possible to

the draw off points from the circuit.

Pipework Connections (General)

WARNINGS

Ensure pipework to and from pump is independently supported to

prevent forces being transferred to inlet and outlet branches of pump.

Do not introduce solder flux to pumps or pump parts manufactured

from plastic. All solder joints should be completed and flux residues

removed prior to pump connection.

Do not allow contact with oil or cellulose based paints, paint thinners

or strippers, acid based descalents or aggressive cleaning agents.

Do not allow scale or debris to enter pump. Fit inline strainers to

eliminate the problem in systems at risk.

Do not install a non-return valve, or devices

which contain non-return valves, in the

suction (inlet) pipework to the pump. The

pump must be free to vent to the supply

tanks at all times.

Noise transmission in pipework can be reduced by fitting flexible hoses to pump inlet and

outlet ports.

An installation pack which includes flexible hoses is available, consult Stuart Turner for

details.

We do not recommend location of the pumps in the roof space, since air locks can easily

result. If there is no alternative, please contact our technical sales department for advice.

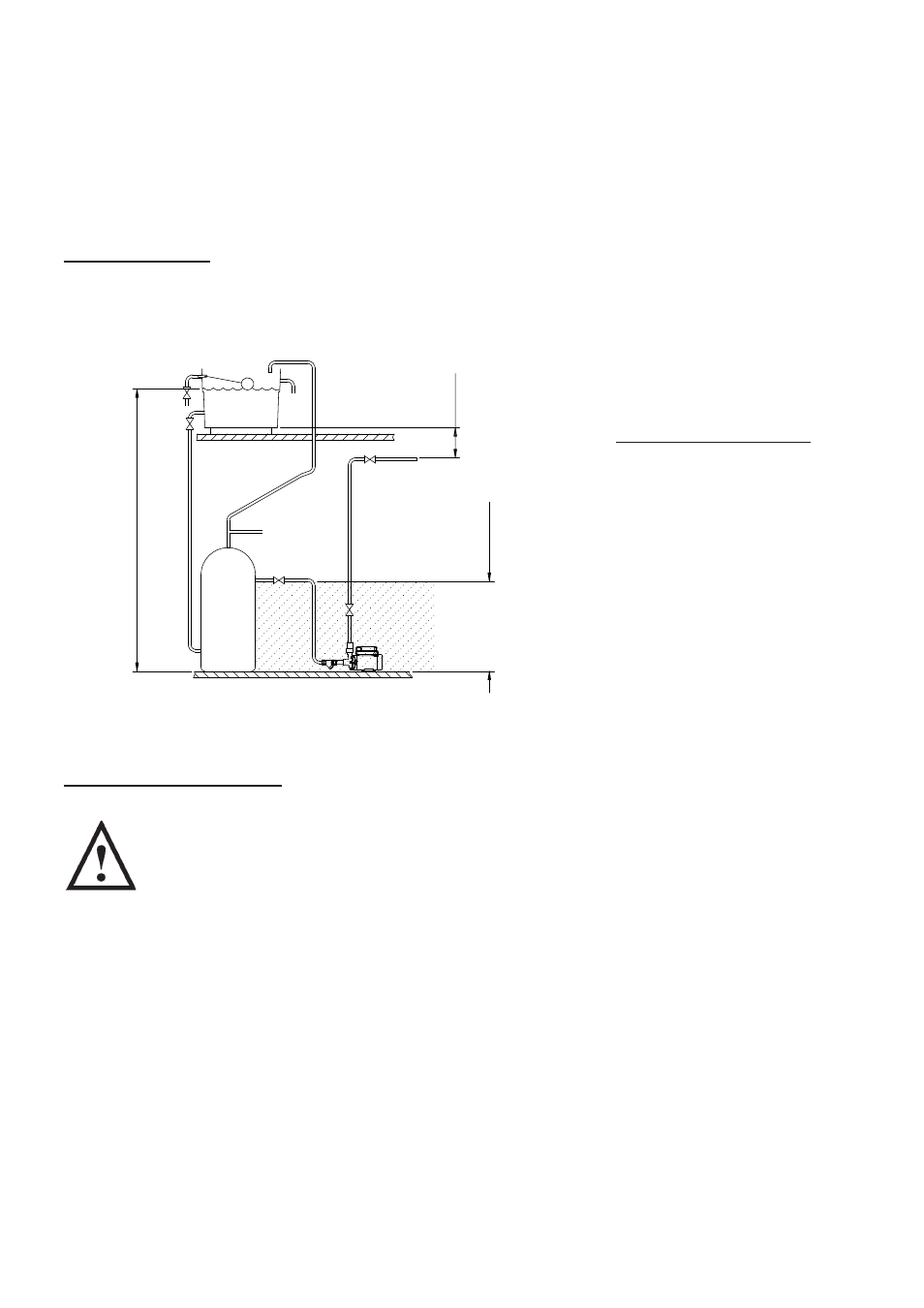

Pump Location (Hot Water Installation)

The preferred pump location is at floor level next to the hot water cylinder or a level that

is below the secondary tapping that feeds the pump. This will ensure the pump has access

to an air free water supply which is important for trouble free operation (Fig. 7).

Fig. 7

Preferred Pump Location

with pump at a level below

draw off tapping in cylinder.

Max. inlet head (consult limits of application section)

Min. inlet head

1

m

100

mm

min

preferred

area

hot water

services