8 trouble shooting guide – Stuart Turner Showermate eco S2.0 bar Twin User Manual

Page 18

- 18 -

8 TROUBLE SHOOTING GUIDE

8.11

Environment Protection: Your appliance contains valuable materials which can

be recovered or recycled.

At the end of the products’ useful life, please leave it at an appropriate local civic

waste collection point.

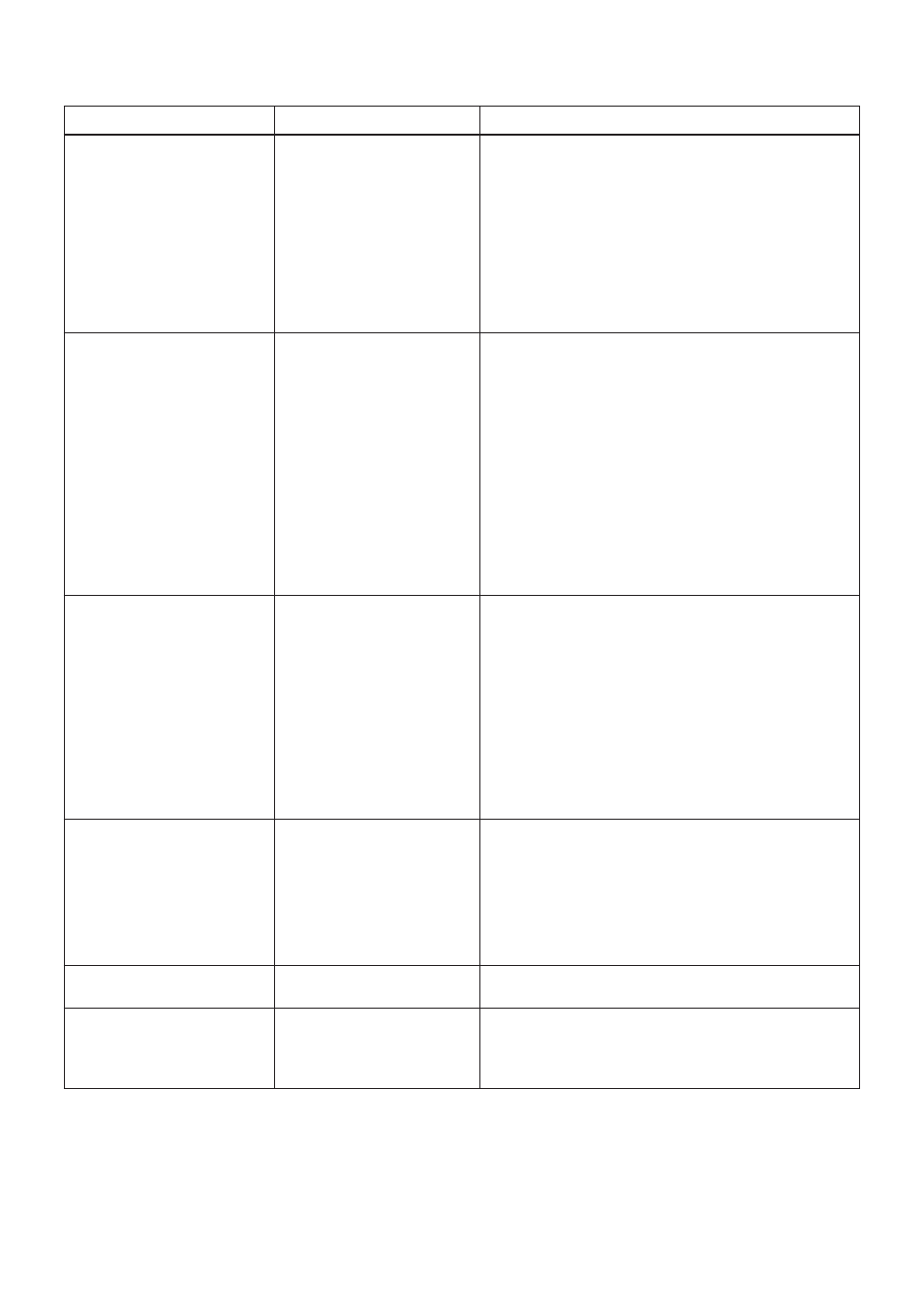

Symptoms

Probable Cause

Recommended Action

Pump will not start.

Insufficient gravity flow.

Check flow rate minimum of 0.8 l/min required on full hot and

cold.

Electrical.

Check power supply.

Check fuse (see fuse section).

Check circuit breaker is set.

Check wiring connections.

Pump jammed.

If motor ‘Buzzes’ switch off power and contact Stuart Turner.

Integral motor thermotrip

activated.

Wait for thermotrip to auto-reset and check that duty point and

run time is within specification (see technical specification).

Reduced/intermittent flow.

Incorrect or no anti-aeration

flange fitted.

Check that the installation complies with installation

instructions.

Incorrect pipe sizes.

Check for correct pipe sizing, see Page 5 - Section 2.19..

Blocked inlet filters.

Clean inlet filters (see maintenance section).

Air in system.

Run system on full hot with pump switched off (ie. gravity

only) for several minutes. Check that vents are fitted as

detailed in instructions.

Hot water temperature set to

high.

Reduce cylinder stat setting to 65

o

C max.

Blocked shower head spray

plate.

Clean in accordance with manufacturers instructions.

No hot water.

Air locked water feed.

Vent hot water pump of air.

Check cold feed to hot water cylinder.

Check water level in cold water tank and that all stopcocks

and isolating valves are open.

Heating source not operating.

Check boiler is switched ‘on’.

Check cylinder thermostat.

Check immersion heater.

Check cylinder contains hot water.

All hot water has been used.

Check tank volume is adequate.

Faulty thermostatic mixer valve.

Consult makers instructions.

Pump runs on with outlets

closed.

Jammed flow switch.

Remove outlet hoses and check that flow switch sits in lowest

position. Check float for free movement.

Damaged reed switch or P.C.B.

If pump continues to run, this indicates a closed circuit in

either the flow switch reed or P.C.B. in the terminal box.

Contact Stuart Turner.

Leak in system.

Check tap washers, w/c valve washers, pipe joints.

Pump starts with all outlets

closed.

Air in system.

Bleed through system without pump running until hot and cold

services run with no air.

Flexible hose leaks

Not fitted correctly.

Check that the hose is pushed firmly onto the pump inlet/

outlet connections and pipework.

Damaged ‘O’-rings.

Check copper pipe ends are cleanly cut and deburred.