Stuart Turner Showermate eco S2.0 bar Twin User Manual

Page 10

- 10 -

Cont ...

3.12

Hose to pipework:

1. The hoses are fitted with plastic push-in connectors, which must only be

connected with the following:

a) 15 mm diameter copper pipe to BS EN 1057 - R250 (half hard) - Table 3.

b) 15 mm plastic pipe to BS 7291 part 1 and part 2 (Table 1), or part 3

(Table 1) plus internal support sleeve*.

* The internal bore of the plastic pipe must be supported against collapse

with the pipe manufacturers recommended support sleeve (pipe insert).

c) Appropriate plumbing fittings that are compatible and will provide a water

tight

connection.

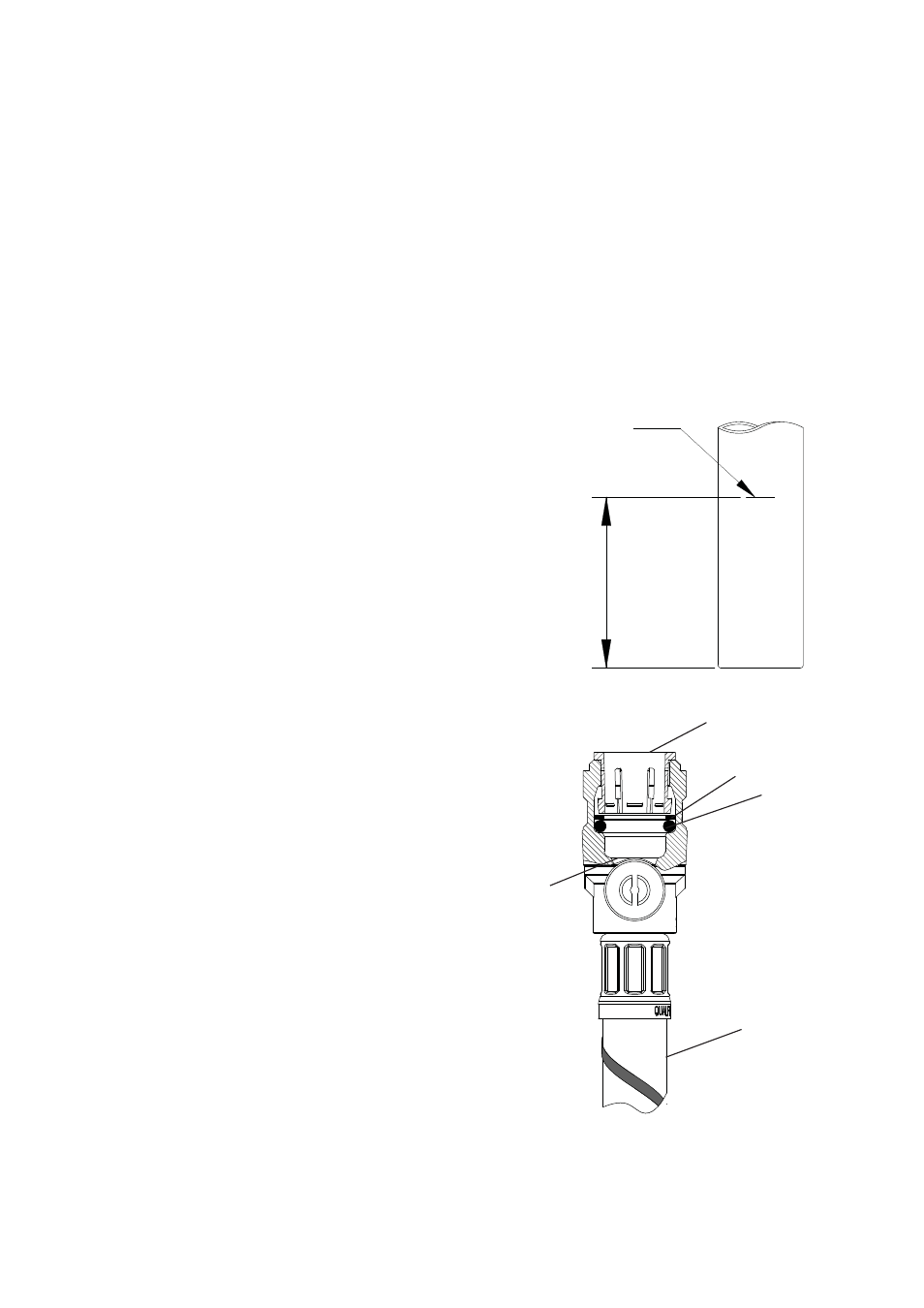

Ensure the pipe is free from all score marks and deformities in the area of the

insertion depth (Fig. 9) and cut the pipe square removing all burrs and sharp

edges to prevent damage to the sealing ‘O’-ring.

2. Prior to inserting pipe into fitting mark

the insertion depth on the wall of the

pipe with a soft pencil at a distance of

31 mm from the end to be inserted

(Fig.

9).

3. Check in the mouth of the

fitting that the ‘O’-ring, nylon

washer and collet are in

position as shown in Fig. 10.

4. Push pipe firmly into fitting,

until pencil mark is level with

the top of the collet and the

pipe stop resistance is felt.

Pull on pipe to check it is

secure and correctly fitted.

5. To release the joint, push pipe firmly into fitting, hold collet down and gently

remove pipe. If the system has been filled with water care should be taken to

isolate pump and towels used to absorb spilled water.

Fig. 9

15 mm Pipe

Pencil

Mark

Insert Depth

31 mm

Fig. 10

Collet

Washer

‘O’-Ring

Flexible Hose

Pipe Stop