Stuart Turner Monsoon Extra S3.0 bar Single User Manual

Page 4

- 4 -

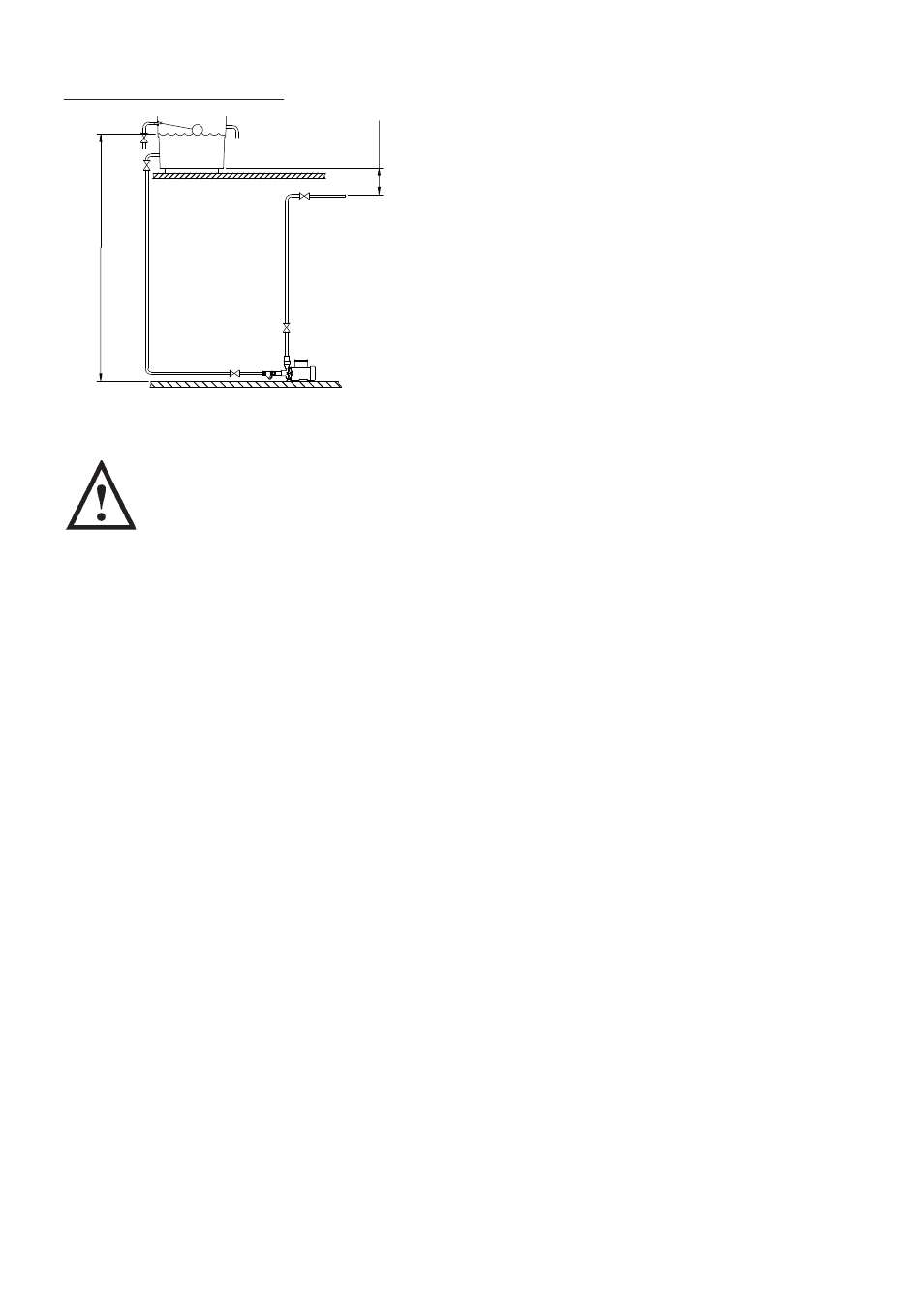

Diagram showing typical cold

water boosting installation.

Cold Water Installation

STEP 2 PIPEWORK CONNECTIONS (General)

WARNINGS:

Ensure pipework to and from pump is independently supported to

prevent forces being transferred to inlet and outlet branches of pump.

Do not introduce solder flux to pumps or pump parts manufactured

from plastic. All solder joints should be completed and flux residues

removed prior to pump connection.

Do not allow contact with oil or cellulose based paints, paint thinners

or strippers, acid based descalents or aggressive cleaning agents.

Always install isolating valves to both suction and delivery pipework.

Do not install a non-return valve, or devices

which contain non-return valves, in the

suction (inlet) pipework to the pump. The

pump must be free to vent to the supply

tanks at all times.

It must be ensured that the water storage capacity is sufficient to meet the flow rates

required by the pump and any other water using fittings and appliances, which may be

operated simultaneously.

As a rule of thumb: assuming a cold water temperature of 10°C and a hot water

temperature of 65°C.

A 6-minute shower using 10 litres/min will consume 40 litres of hot water and 20 litres

of cold. This means the total quantity of water used from the cold water storage tank

will be 60 litres (40 + 20).

A 10-minute shower using 15 litres/min will consume 100 litres of hot water and

50 litres of cold. This means the total quantity of water used from the cold water

storage tank will be 150 litres (100 + 50).

On installations where there are high flow requirements e.g. multiple showers or body

jets.

A 10-minute shower using 45 litres/min will consume 300 litres of hot water and

150 litres of cold. This means the total quantity of water used from the cold water

storage tank will be 450 litres (300 + 150).

Fig. 4

10

metres max

1

metre min

100

mm

min