Iv. operation – Sterling MS User Manual

Page 16

— 16 —

DX COIL EQUIPPED UNITS (OPTIONAL)

See Coil Installation/Maintenance Manual for Refrigerant

Piping, Liquid and Suction Line Components, Refrigerant

Charging and Thermal Expansion Valve Adjustment.

Remove coil cabinet access door located next to blower

section. Cut holes in fi xed door to allow suction and liquid

line passage. Provide weatherproof seal around suction

and liquid lines at piping plate when installed.

The DX Coil has a 300 ft/min. (1.524 m/s) minimum and

a 600 ft/min. (3.048 m/s) maximum velocity through the

coil requirement. This is due to prevention of coil icing or

condensate blow-off. To calculate the velocity through the

coil, apply the following formula:

Velocity =

Cooling Air Flow in CFM (m

3

/s)

through the coil

Coil Surface Area in ft

2

(m

2

)

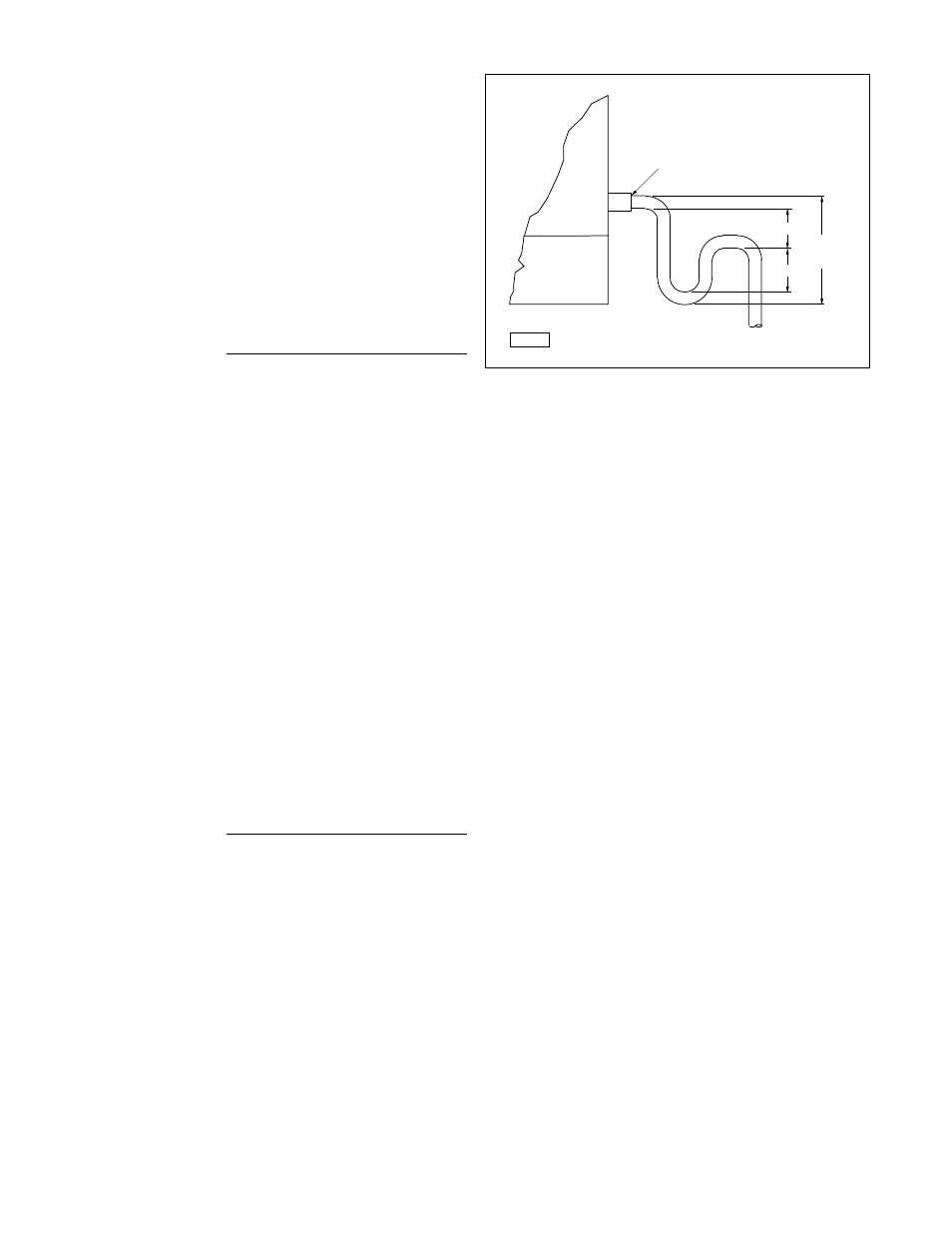

Condensate Drain piping must have a P-trap in line

immediately downstream of drain pan connection,

external to the unit, to prevent possible outside air

leakage into unit. The P-trap shall be of sufficient

differential to overcome negative pressure of the indoor

air blower. A minimum height difference of 2" (51mm) is

required (See Figure 16). Before unit operation begins,

the P-trap must be primed with either water (summer) or

glycol (winter).

CHILLED WATER COIL

EQUIPPED UNITS (OPTIONAL)

See Coil Installation/Maintenance Manual for General

Coil Piping Recommendations. Remove coil cabinet

access door, cut holes in door to allow chilled water piping

passage. Provide weatherproof seal around chilled water

pipes at piping plate when installed.

The Chilled Water Coil has a 600 ft/min (3.048 m/s)

maximum velocity through the coil requirement. This is

due to prevention of condensate blow-off. To calculate

the velocity through the coil apply the following formula:

Velocity =

Cooling Air Flow in CFM (m

3

/s)

through the coil

Coil Surface Area in ft

2

(m

2

)

Condensate Drain piping must have a P-trap in line

immediately downstream of drain pan connection,

external to the unit, to prevent possible outside air leakage

into unit. The P-trap shall be of suffi cient differential to

overcome negative pressure of the indoor air blower. A

minimum height difference of 2" is required (See Figure

16). Before unit operation begins, prime P-trap with either

water (summer) or glycol (winter).

EVAPORATIVE COOLER

EQUIPPED UNITS (OPTIONAL)

Refer to Evaporative Cooler Installation and Service

Manual for water and electrical connections.

Figure 16 - Drain Pan Connection

IV. OPERATION

GENERAL INFORMATION

Refer to Separated Combusion Indoor Gas-Fired Duct

Furnace Installation and Service Manual for specifi c

information regarding the heating operation of this unit.

All units are equipped with an intermittent ignition pilot

system. The pilot is lit and extinguished each cycle of unit

heating operation.

On natural gas units, the ignitor will continue to spark and

pilot gas will continue to fl ow until the pilot fl ame is proven.

LP (propane) units are equipped with 100% lockout. The

lockout function shuts off the main and pilot gas valves if

the pilot gas fails to ignite within 90 seconds of the onset

of trial for ignition.

The gas control system operates at 24 VAC and is

supplied by a stepdown transformer found in the electrical

cabinet that will match the unit line voltage specifi ed. See

Figures 13 through 15 for unit controls location.

Do not use a thermostatic fan control switch when either

two-stage fi ring or modulated gas controls are used.

GAS CONTROL SYSTEM

The standard unit comes equipped for single stage

operation. Unit heating operation is accomplished at

full input.

Each duct furnace is equipped with an individual ignition

control system which consists of the following components:

ignition control module, gas valve and pilot burner.

The ignition control module is the heart of the ignition

control system. This control initiates all gas fl ow, provides

means to light the pilot burner, proves and monitors the

pilot burner operation.

Drain Pan Connection

H

Total

Height

of Trap

X = 1/2 “H”

H = At Least 1 Inch Plus

Casing Static Pressure

D3887

Total Height Of Trap = X+ H + (1-1/2 X Pipe Diameter)

(without Insulation)

Unit

Housekeeping

Pad

X